Axial-flow type water control reducing valve

A pressure reducing valve, axial flow technology, applied in the field of axial flow water control pressure reducing valve, can solve the problems of high cost and short service life, and achieve the effect of low manufacturing cost, fewer failure points and good medium flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

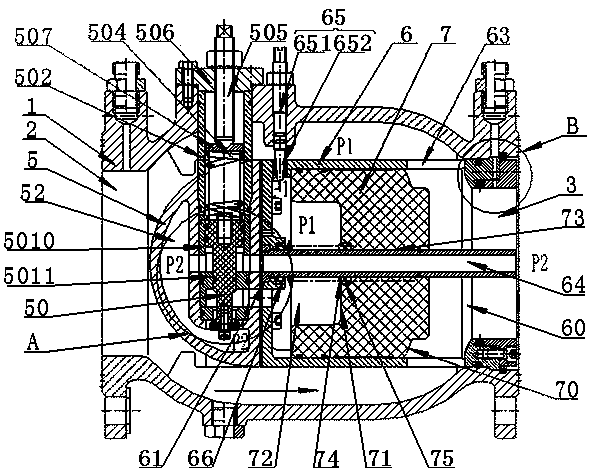

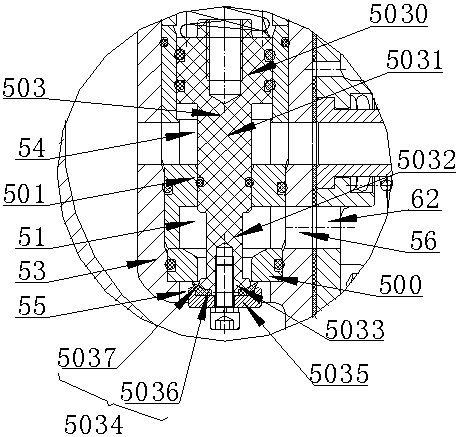

[0024] Combine below Figures 1 to 3 Describe the structure and content of the invention of the axial-flow water-controlled pressure reducing valve of the present invention.

[0025] An axial flow water control pressure reducing valve, comprising a valve body 1, a water inlet 2 and a water outlet 3 arranged at both ends of the valve body 1, a first valve seat 4 installed at the water outlet 3, arranged inside the valve body 1 and The pressure relief body 5 near the water inlet, the pressure relief valve 50 installed in the pressure relief body 5, the piston ring 6 installed on the pressure relief body 5, and the piston ring 6 installed in the piston ring 6 and sealed with the first valve seat 4 piston7.

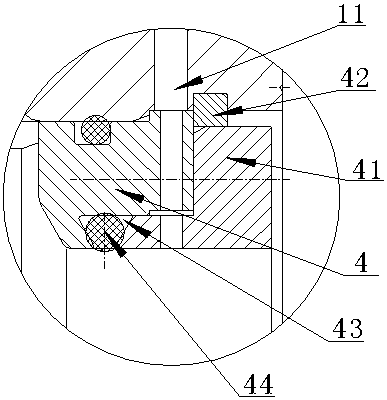

[0026] Pressure measuring holes 11 are provided on the valve body 1 at positions corresponding to the water inlet 2 and the water outlet 3 . A pressure measuring instrument is installed on the pressure measuring hole 11 .

[0027] The first valve seat 4 is sealingly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com