Straight-through type pneumatic discharging valve

A discharge valve, straight-through technology, used in sliding valves, multi-port valves, valve details, etc., can solve the problems of hidden safety hazards, inconvenient applications, inconvenient installation, etc., to achieve control and reliability, simple and compact structure, and manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

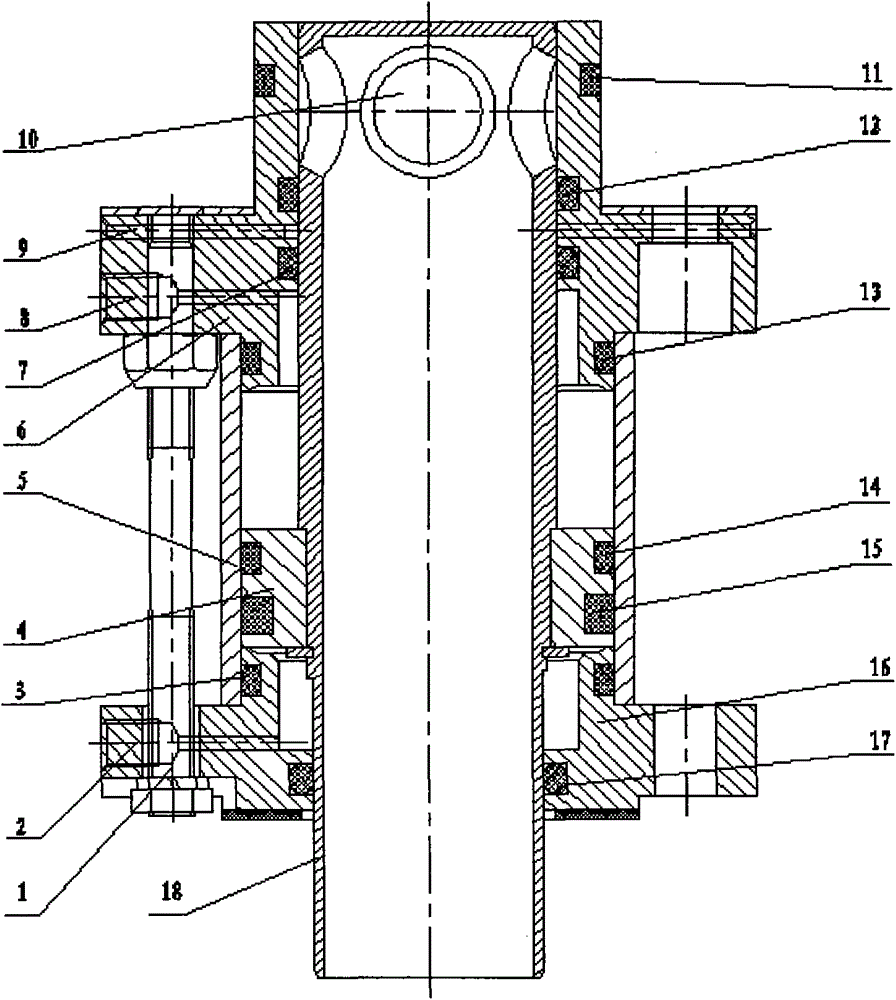

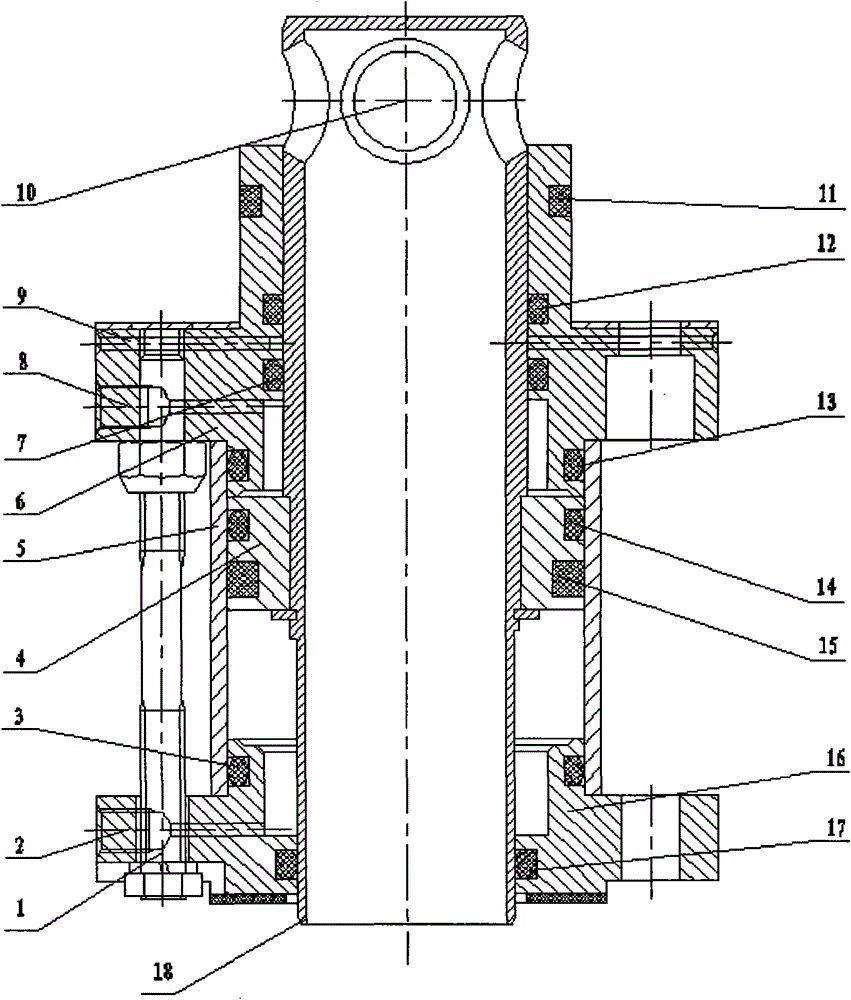

[0015] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as figure 1 , 2 As shown, a straight-through pneumatic discharge valve includes a piston rod 18, a lower end cover 16, a first sealing ring 3, a piston 4, a magnetic ring 15, a cylinder barrel 5, an upper end cover 6, and a second sealing ring 7. The piston rod 18 is a hollow pipe with a closed upper end and an open lower end. Four feeding materials 10 are evenly distributed in the circumferential direction of the upper part of the piston rod 18. The four feeding materials 10 are all tapered holes, and the diameter of the lower end of the tapered hole is 25mm. The angle is 60°, the middle part of the piston rod 18 is provided with a shaft shoulder, and the piston 4 is fixed on the shaft shoulder of the piston rod 18 through a circlip; the magnetic ring 15 is stuck on the piston 4, and the width of the magnetic ring 15 is 3-5mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com