Welding clamp for cushion frame of sixty-percent seat

A technology for welding fixtures and cushions, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as difficult positioning welding, easy deformation of steel wire, and increased welding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

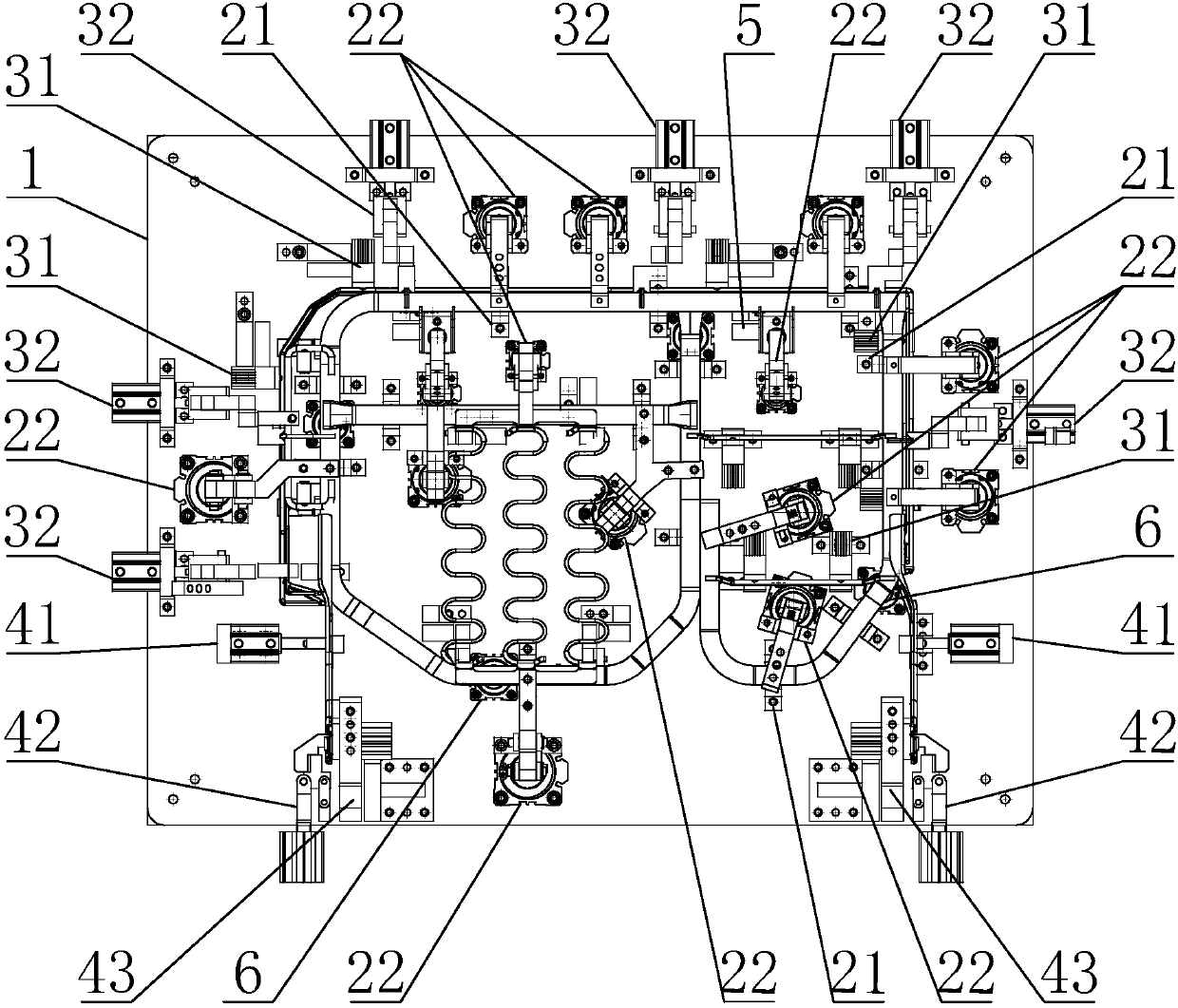

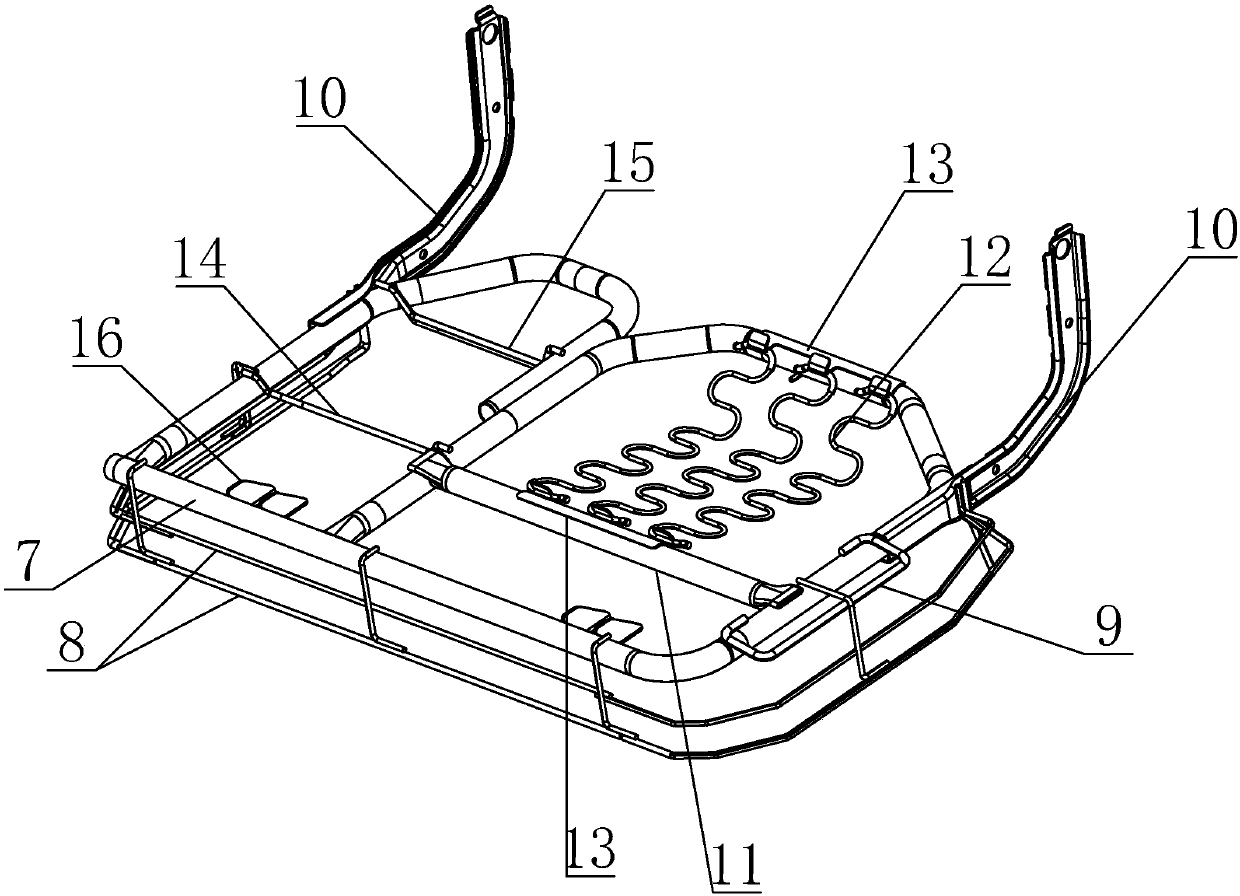

[0032] like figure 1 and 2 Shown: a welding fixture for a six-point seat cushion frame, which consists of a bottom plate 1 for placing the various components of the seat cushion frame, a frame tube positioning mechanism, a front brace steel wire positioning mechanism, and a connecting arm positioning mechanism on the bottom plate It is composed of the connecting bracket hole positioning seat 5; the top cylinder 6 is distributed directly below the corresponding frame pipe.

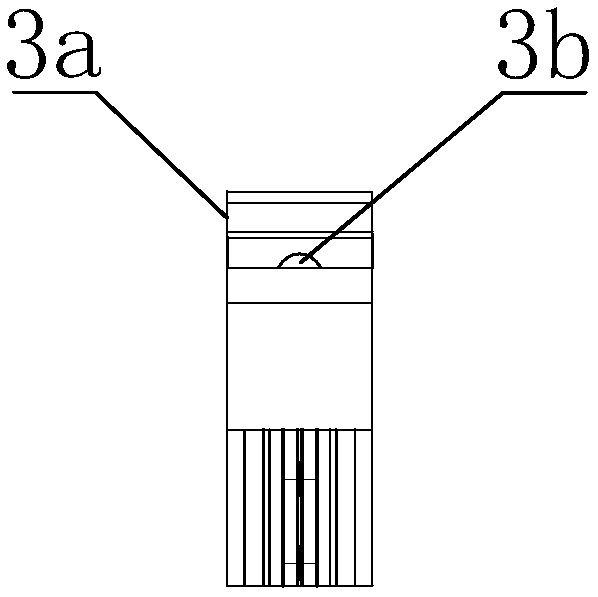

[0033] like figure 1 As shown: the frame tube positioning mechanism is composed of a support seat 21 and a pressing device 22; as Figure 7 The top of the supporting seat 21 shown is a "U" shaped groove, and the supporting seat 21 is evenly distributed along the frame tube and the rear seat horizontal tube, and the pressing device 22 is arranged along the periphery of the frame tube, the rear seat horizontal tube and the The connecting bracket is arranged, and the said pressing device 22 corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com