Brace-shaped steel wire welding fixture in sextant seat cushion skeleton

A welding jig and steel wire technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increased welding difficulty, difficult positioning welding, and deformation of steel wire, so as to ensure the balance of force and facilitate the The effect of positioning and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

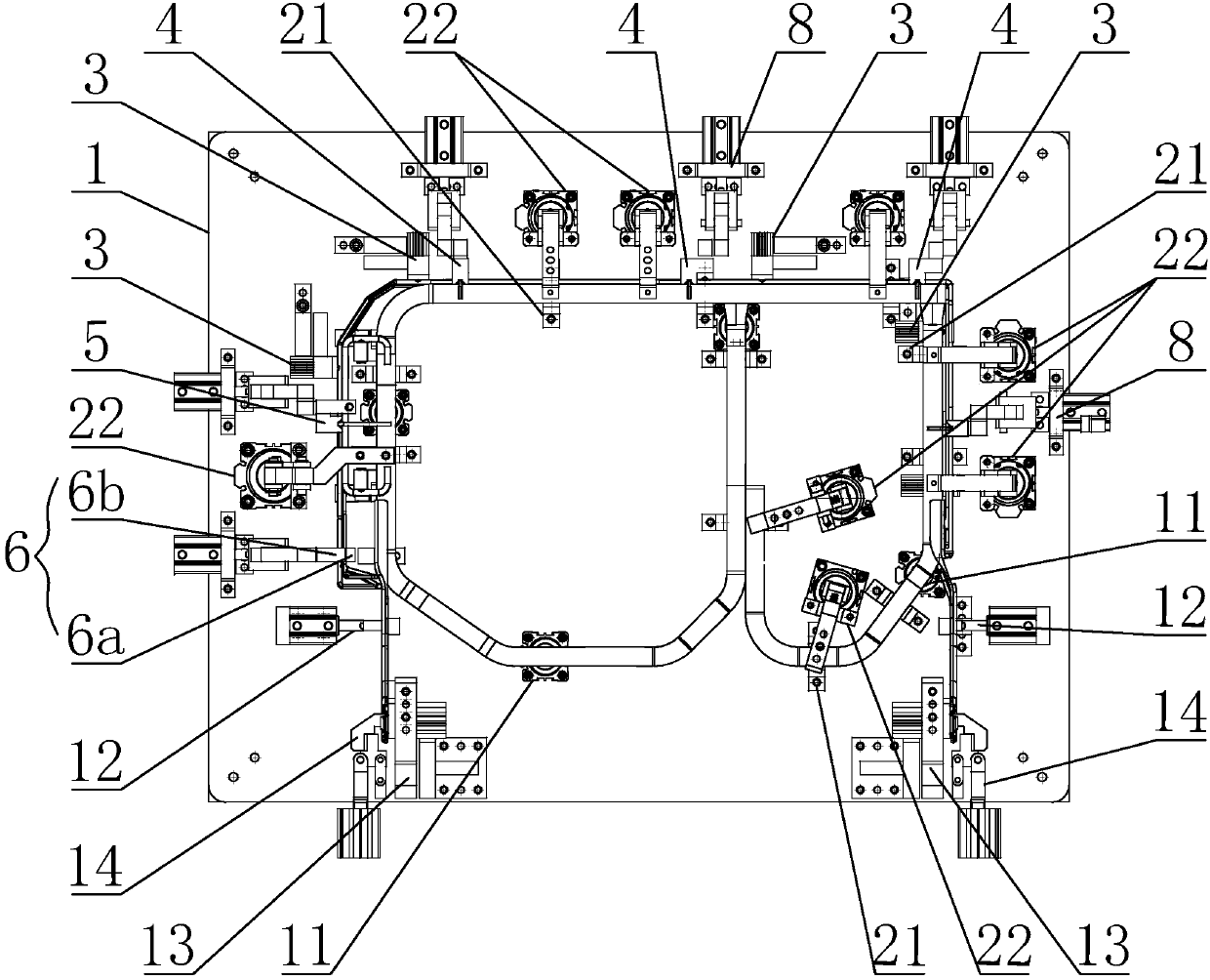

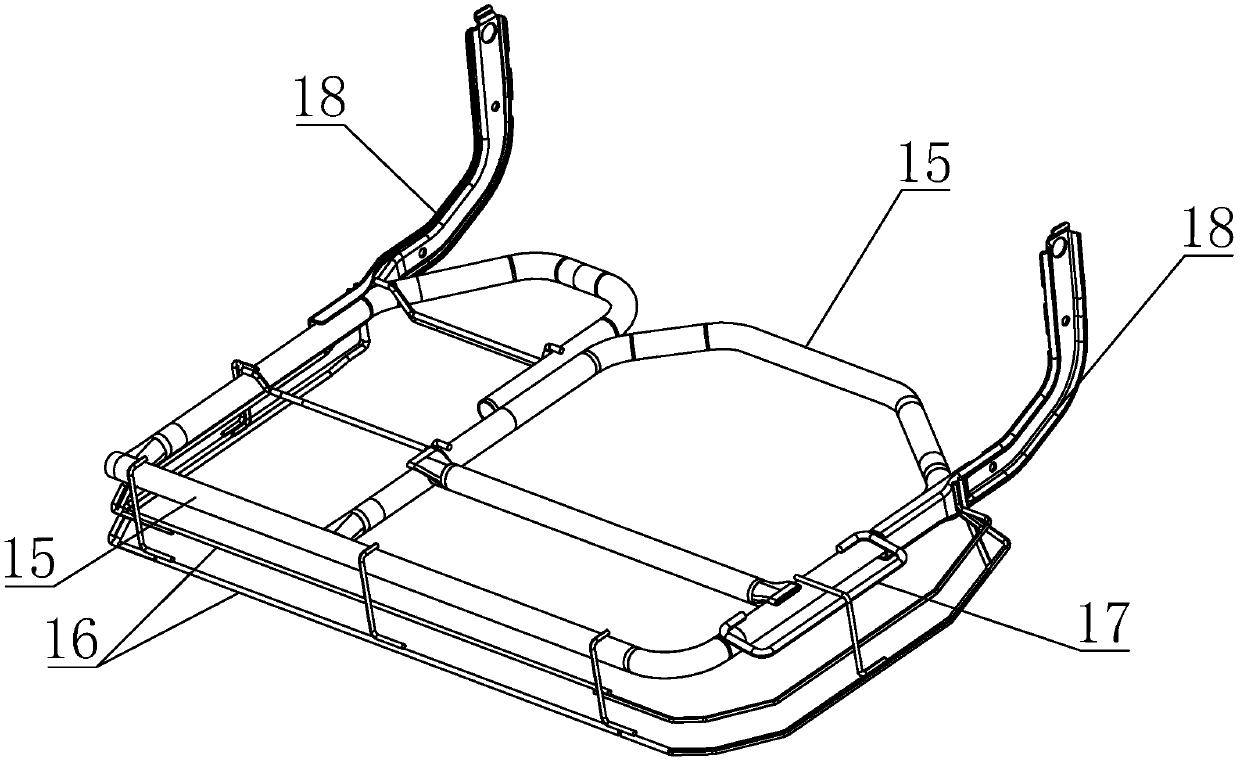

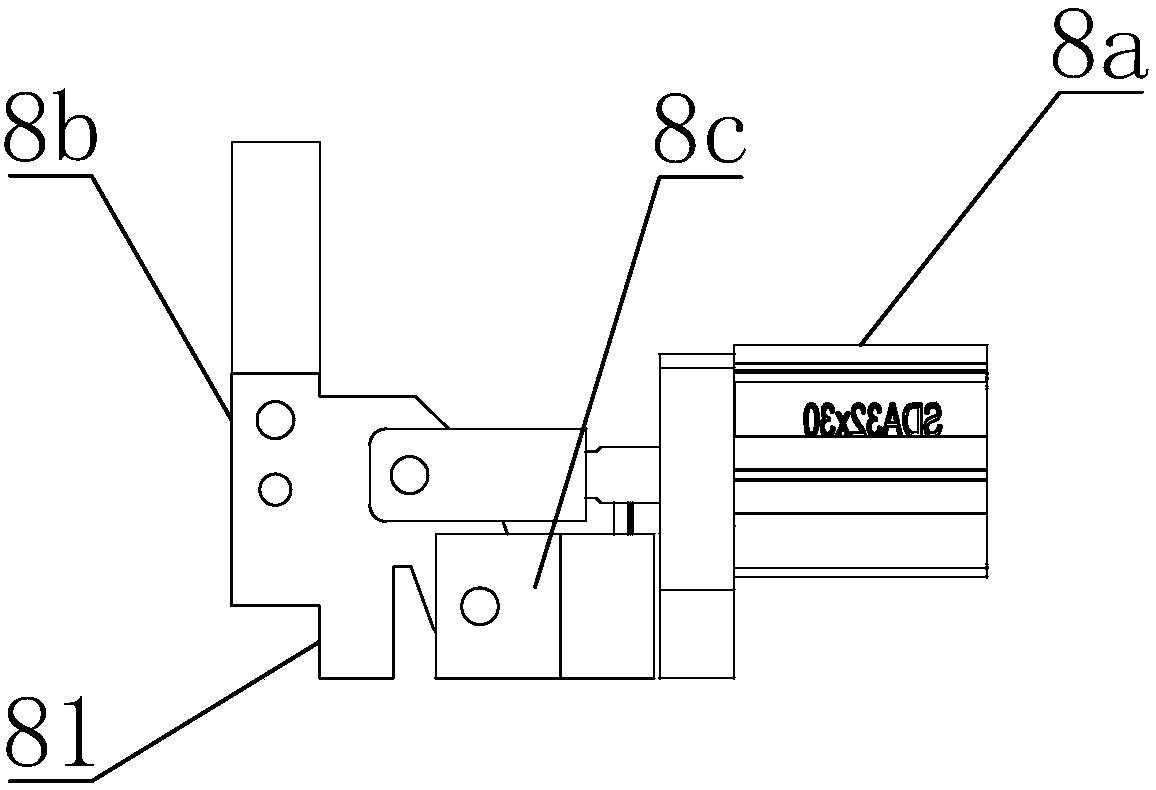

[0032] Such as figure 1 with 2 As shown in and 6: a six-point seat cushion frame middle brace steel wire welding fixture, consisting of a bottom plate 1 used to place the components of the seat cushion frame, a positioning mechanism provided on the bottom plate, a lifting card seat 3, a first The compression block 4, the second compression block 5, the clamping block 6 and the seat side support-shaped steel wire positioning block 7; the positioning mechanism is evenly distributed along the frame tube and supports positioning, such as Picture 9 Shown: the lifting card seat 3 is composed of a slot seat 3a provided with a limiting wire and a pin 3b pushed and clamped by the cylinder, and the lifting card seat 3 is evenly distributed along the lower side of the front support-shaped wire While lifting the limit, the first compression block 4 is located at the front and right side of the seat front brace steel wire and presses the seat front brace steel wire to the frame tube, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com