Automobile rear tail door push rod wire harness fixing structure

A wire harness fixing and rear tailgate technology, which is applied in the field of auto parts, can solve problems such as damage to the skin of the wire harness, affecting product performance, and affecting the normal operation of the tailgate push rod. The effect of rainwater entering the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

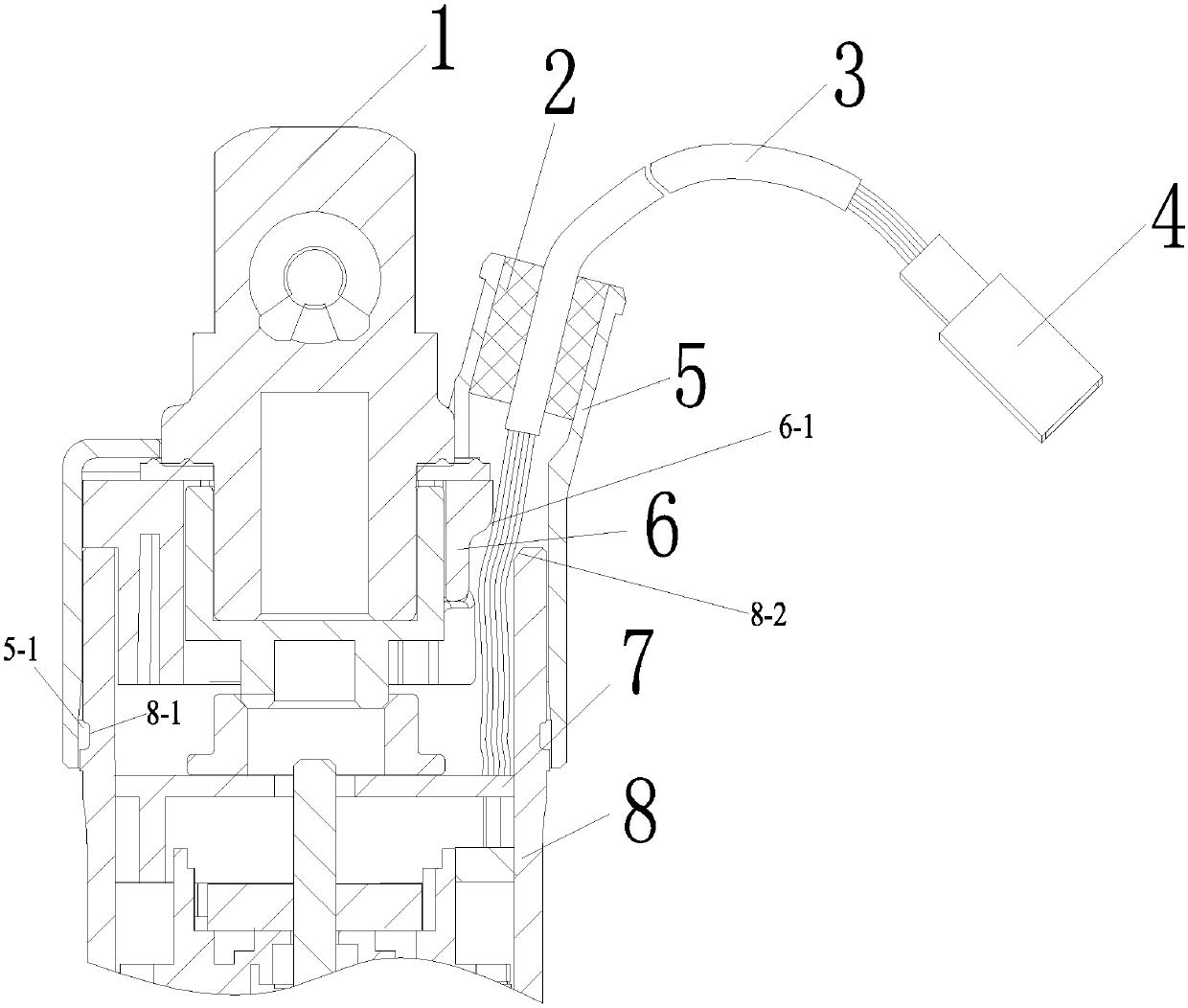

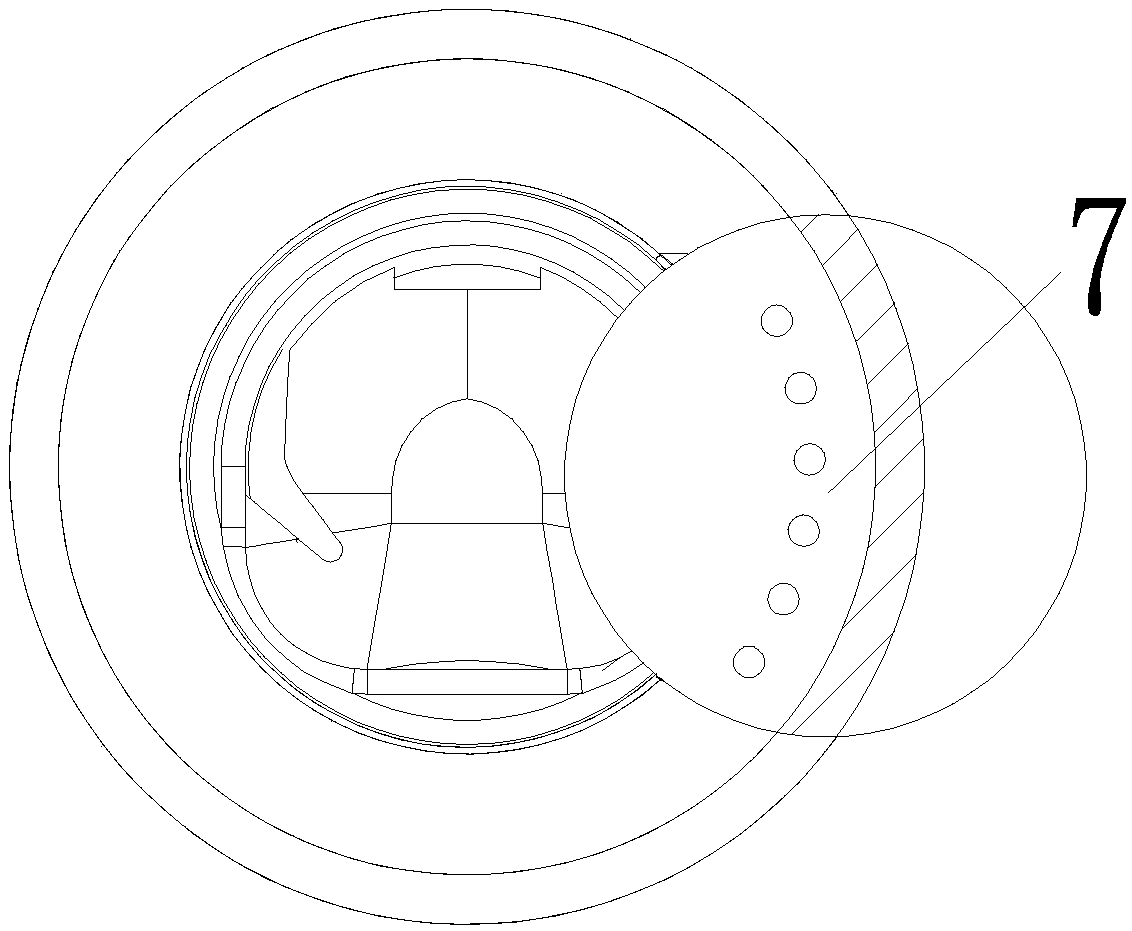

[0012] figure 1 , 2 It includes ball head 1, rubber plug 2, wire harness 3, plug 4, outlet sleeve 5, limit protrusion 5-1, connector 6, arc transition part 6-1, circuit board 7, outer tube 8, Ring groove 8-1, chamfered portion 8-2, etc.

[0013] Such as figure 1 , 2 As shown, the present invention is an automobile rear door push rod wiring harness fixing structure, including a ball head 1, a connector 6 is provided on the ball head 1, an outer tube 8 is fixed on the outside of the connector 6, and an outer tube 8 is arranged in an inner cavity The circuit board 7, the outer tube 8 and the outlet sleeve 5 are fixedly connected. One end of the wire harness 3 is connected to the terminal on the circuit board 7, and the other end of the wire harness 3 passes through the outer tube 8 and extends from the outlet sleeve 5. The outlet end is provided with a rubber p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com