Special multi-position output control structure for liquid flow

A liquid flow and control structure technology, applied in the direction of valve housing structure, multi-way valve, valve device, etc., can solve the problems of unable to meet the liquid flow control of complex structure, high maintenance cost, unfavorable wide use, etc., to achieve stable flow regulation Good performance, high assembly efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

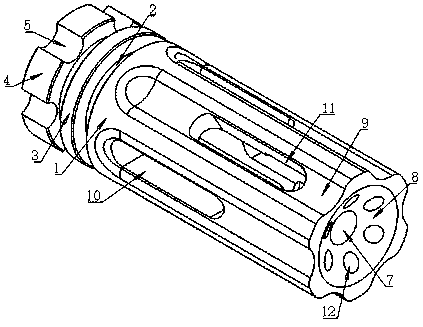

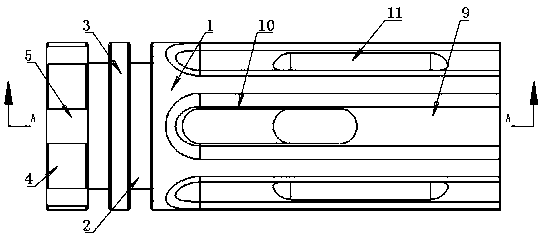

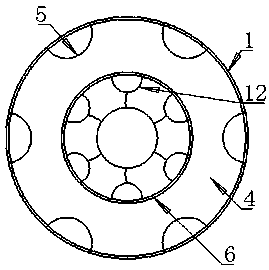

[0018] like Figure 1 to Figure 7 As shown, a special liquid flow multi-position output control structure can be assembled at the interface position of the pipeline structure. When the transfer pipelines in different directions are installed at the pipeline interface position, the control structure can easily realize different directions in different directions. Flow size control,

[0019] It is more convenient to use and can meet the requirements that the traditional switch valve structure cannot meet. This part is more convenient to use, and the tightness of the assembly connection is better. The flow rate of the output position is adjusted through the output hole structure of the spherical structure, so that the liquid is output. The speed can be adjusted freely, and the production cost is lower, and the effect of controlling the liquid flow is better. It includes a cylindrical control structure main body 1, which is the main part of the control structure and is used to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com