Assembling structure of lamp holder and bulb

An assembly structure and light bulb technology, applied to lighting devices, components of lighting devices, light source fixing, etc., can solve the problems of easy electric shock, potential safety hazards, troublesome bulb replacement, etc., and achieve the effect of convenient replacement and avoiding electric shock accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

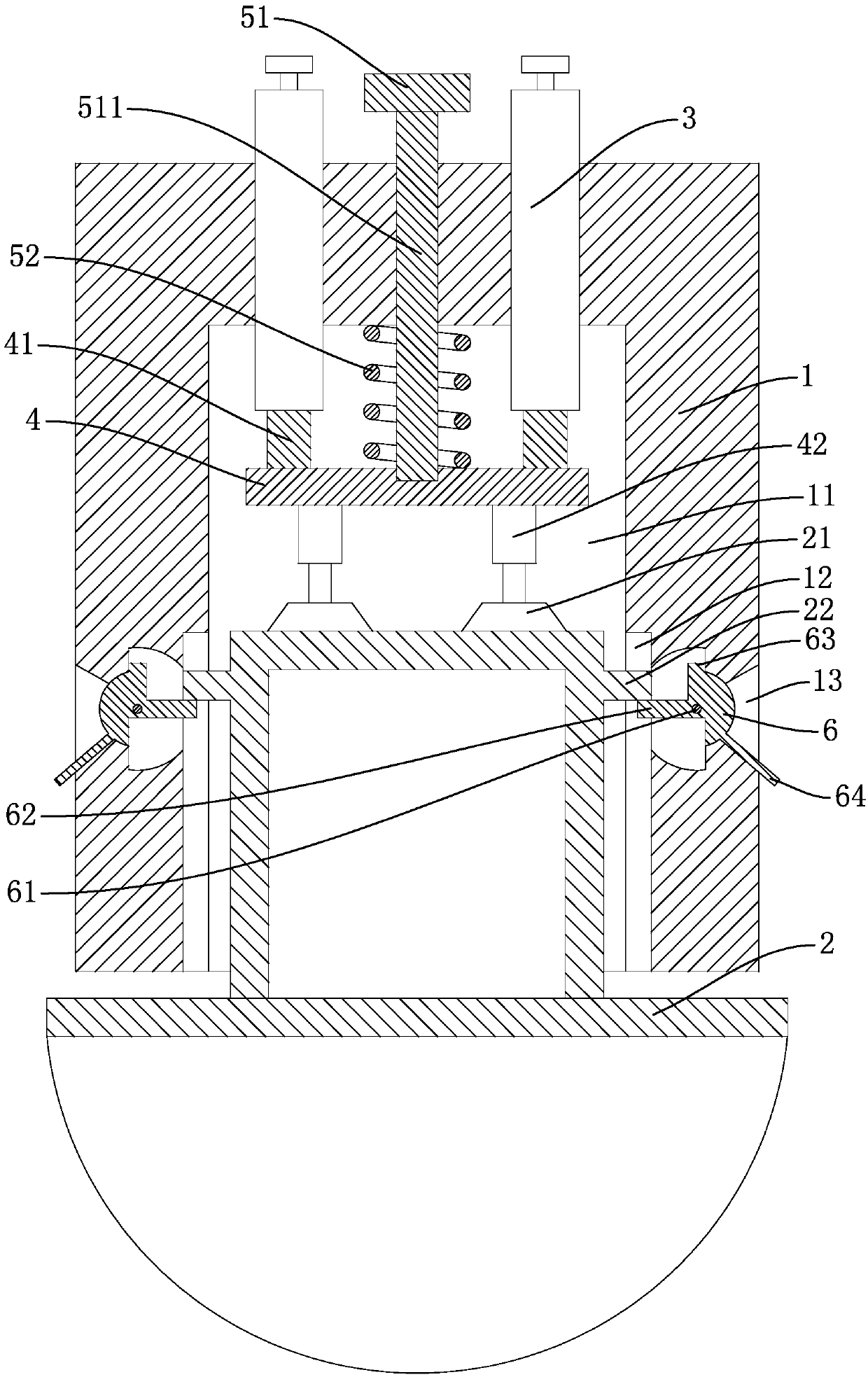

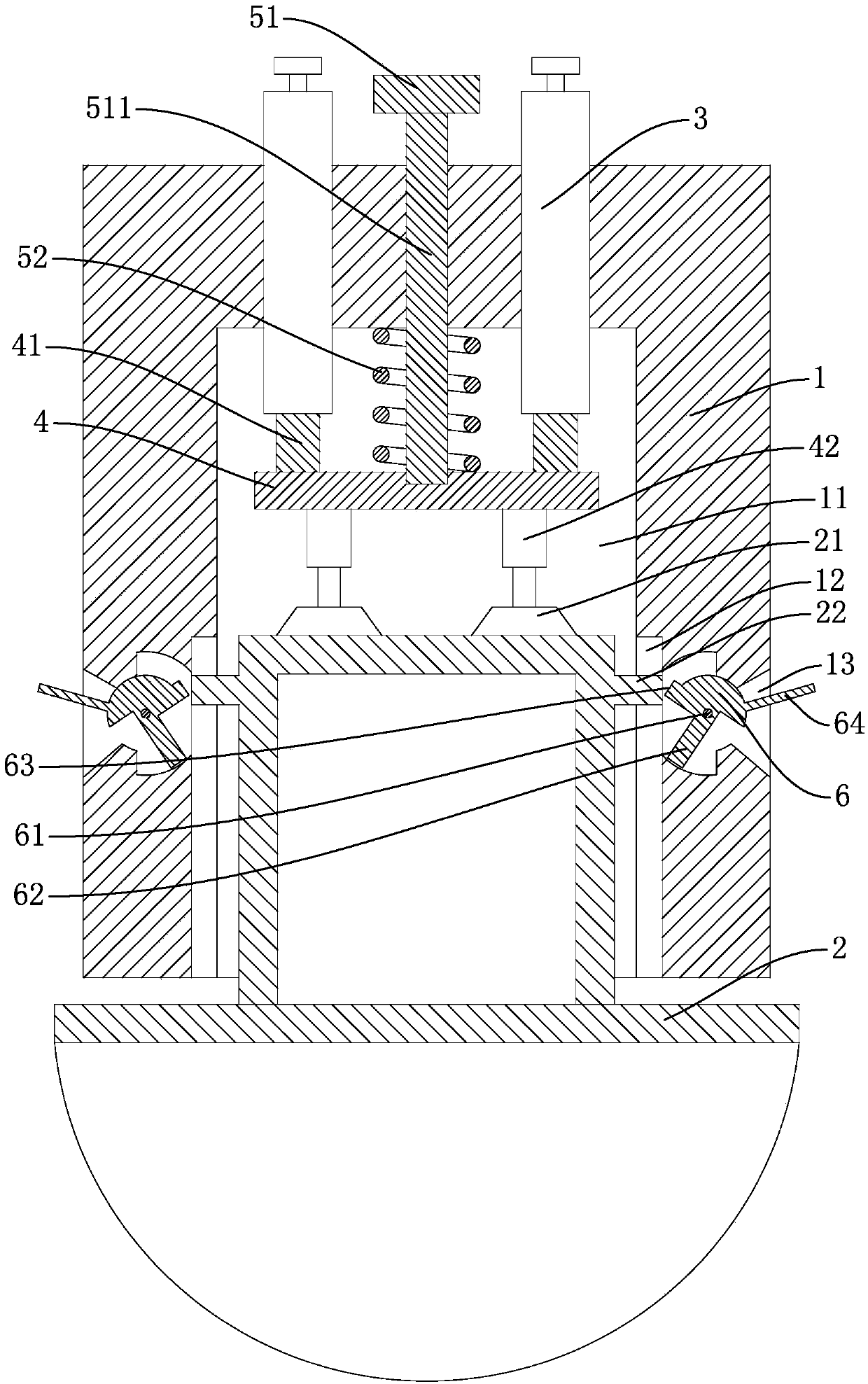

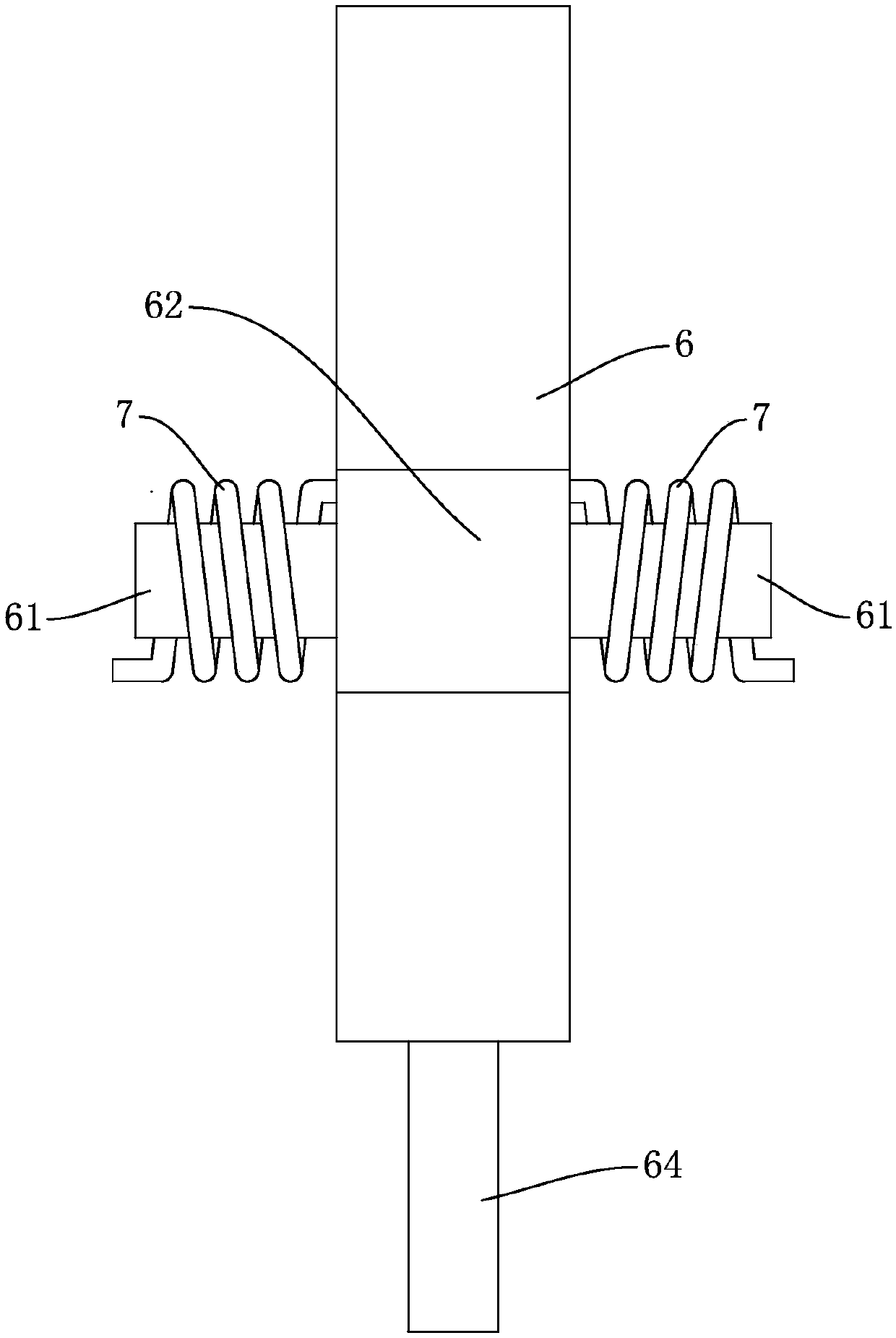

[0013] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] An assembly structure of a lamp holder and a light bulb, comprising a case 1 with a cavity 11 inside and an open bottom end, a light bulb 2 is installed on the case 1, the upper end of the light bulb 2 is inserted into the cavity 11, and the cover 1 A pair of terminal posts 3 are fixed on the top, and the terminal posts 3 extend into the cover case 1 after penetrating the cover case 1. A circuit board 4 is arranged in the cover case 1 above the bulb 2, and a circuit board 4 is fixed on the upper end surface of the circuit board 4 for wiring. A pair of conductive contacts 41 are fixed on the lower end of the column 3 to achieve electrical connection, and a pair of elastic conductive pins 42 are fixed on the lower end surface of the circuit board 4 to abut against the contact 21 on the upper end of the bulb 2 to achieve electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com