Web liner with partially embedded filaments

A precursor and liner technology, applied in the direction of film/sheet release liner, film/sheet adhesive, thin material processing, etc., can solve the problem of damaged appearance, pressure-sensitive adhesive damage, and labor-intensive And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

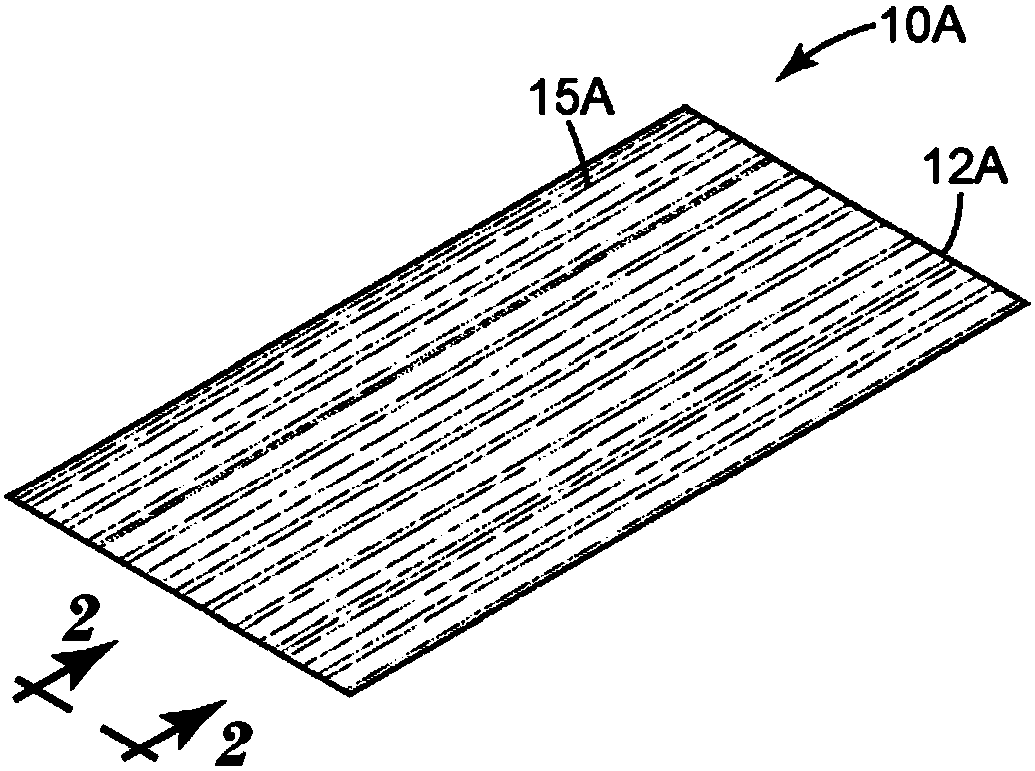

[0082] Example 1: Pad with partially embedded strands

[0083]Liner L1, release surface facing up, was fed through a heated nip consisting of a rubber roll on top (Roll 1 ) and a steel roll on the bottom (Roll 2 ) at 60 ft / min. The nip pressure was 40 psi. The nip heat exchanger for both rolls was set to 240°F (116°C) and the exiting pad temperature was estimated to be 206°F with an infrared thermometer. Resin R1 was heated at 480°F (249°C) in an extruder with a screw diameter of 50 mm and an L / D of approximately 32:1 and passed through a 2 inch die with 60 holes per inch Extrude onto a room temperature steel roll (roll 3). The die holes were drilled with a 0.008 inch (0.20 mm) opening. The extrusion rate was measured to be an average of 0.14 lb / hr, but varied due to the low extruder speed.

[0084] The resulting extruded strand is drawn over 5 inches and contacts the side of a smooth steel roll (Roll 3) and is then clamped with a heated pad on a heated roll (Roll 2) so ...

Embodiment 2

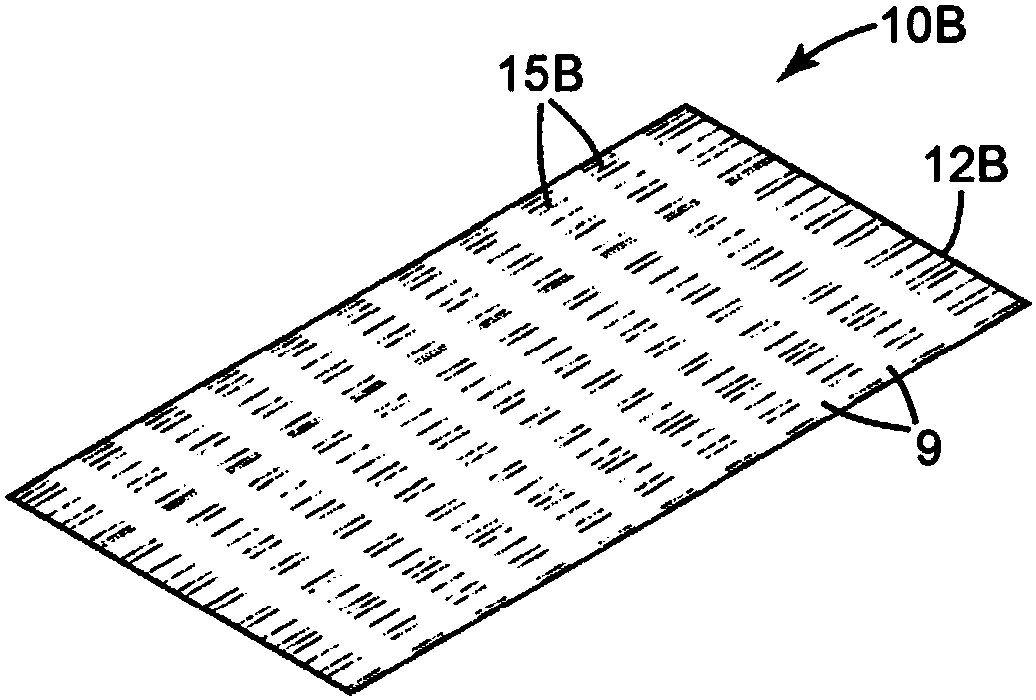

[0086] Example 2: Film laminated to a liner with embedded filaments

[0087] A length of pad with embedded strands (according to Example 1 ) was placed on a hard flat table with the embedded strands facing up. A slightly larger length of reflective graphic film F1 is then laminated to the liner: First, a small length of film F1 is aligned with the liner containing the strands and manually secured to the bench. A rubber roller (similar to p / n EDI: 19560, available from Marshalltown Company, Marshalltown, IA) was then placed on the adhered portion of film F1 and advanced so that Film F1 was laminated to a liner with embedded filaments.

Embodiment 3

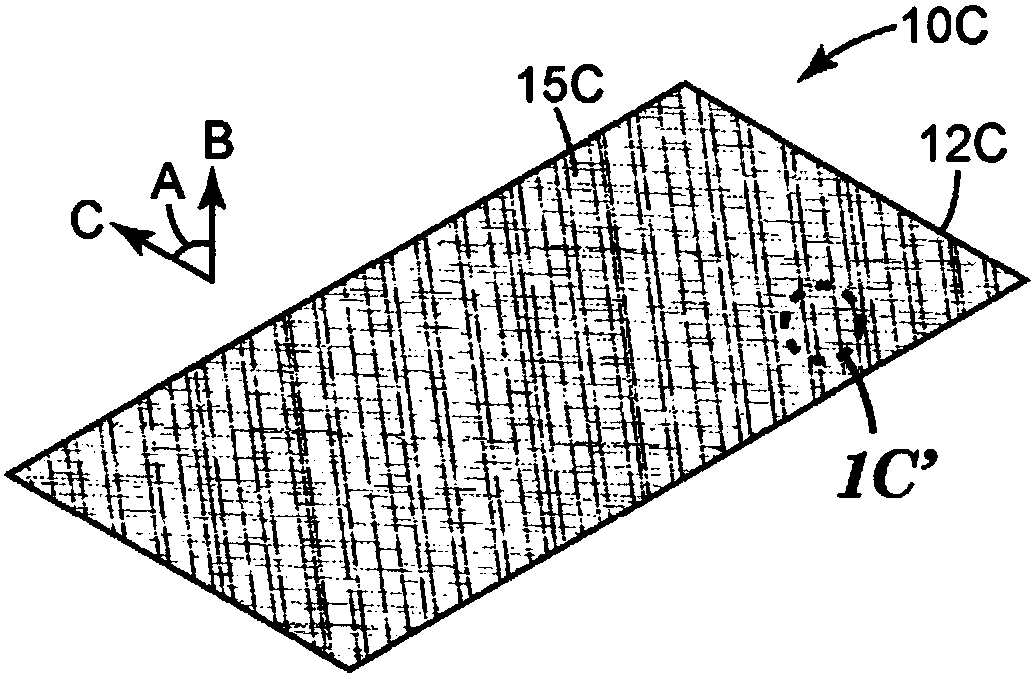

[0088] Example 3: Repositionable adhesive film with strands

[0089] The laminate of Example 2 was separated manually, thereby removing the liner L1 used in Example 1 from the film F1. When the two films were separated, the filaments remained on the adhesive side of film F1. This forms an adhesive-backed film with partially embedded strands.

[0090] An adhesive-backed film with partially embedded strands is placed adhesive side down on a surface with no additional pressure applied (i.e., no hard pressing), thereby rendering the strands resistant to adhesion The agent layer is in close contact with the surface. The adhesive-backed membrane with partially embedded strands was then moved and repositioned by pulling on the corners of the membrane. Once the membrane is lightly pressed, the membrane adheres to the surface. When pressed harder, more adhesive bonds to the surface, increasing bondability.

[0091] Another sample of the adhesive-backed film with partially embedd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com