Method and apparatus for producing a membrane-electrode assembly for a fuel cell

A membrane electrode group and fuel cell technology, which is applied to fuel cell components, fuel cells, sealing/supporting devices, etc., and can solve problems such as the difficulty in realizing the connection of components of the membrane electrode group

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

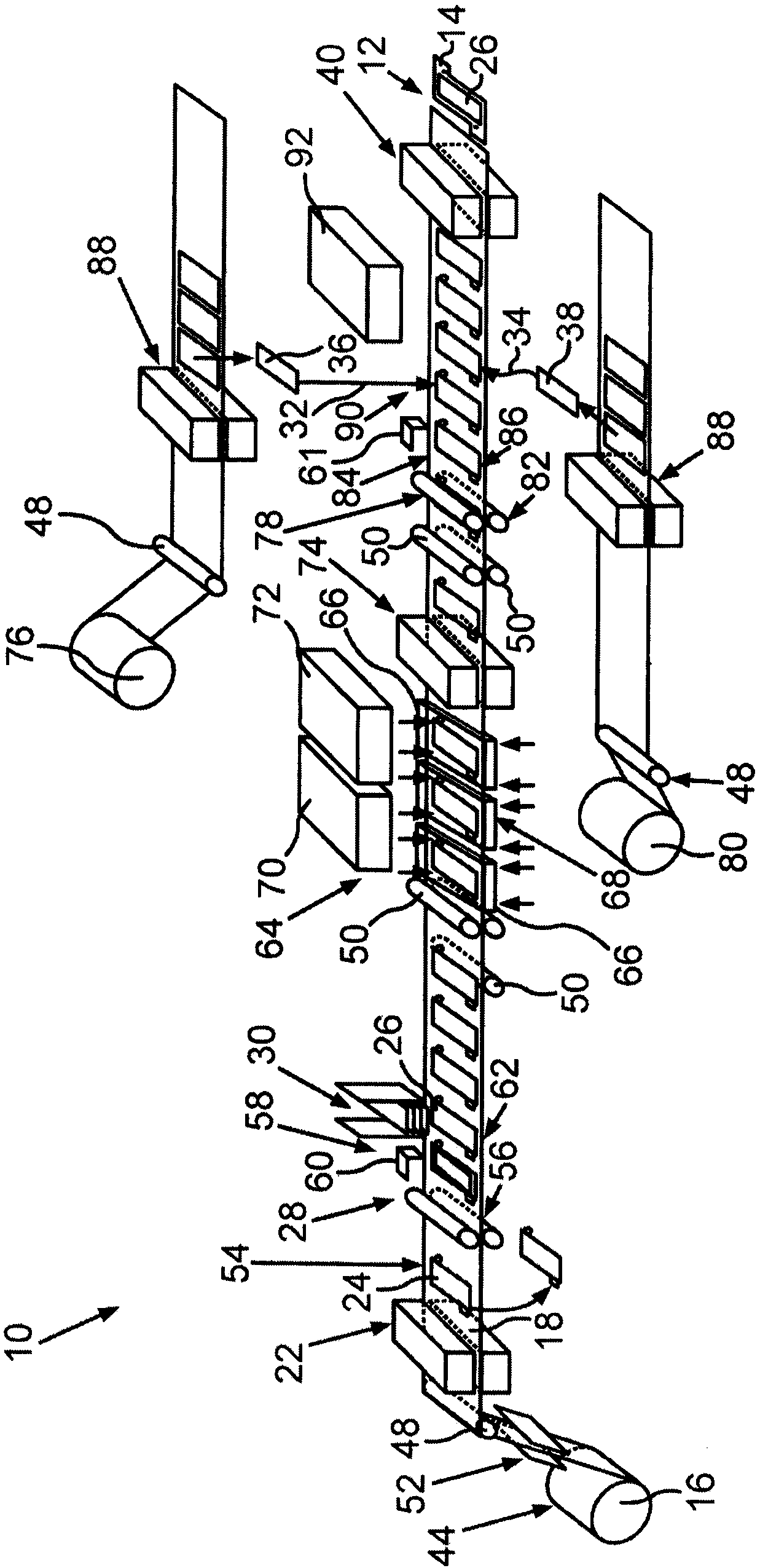

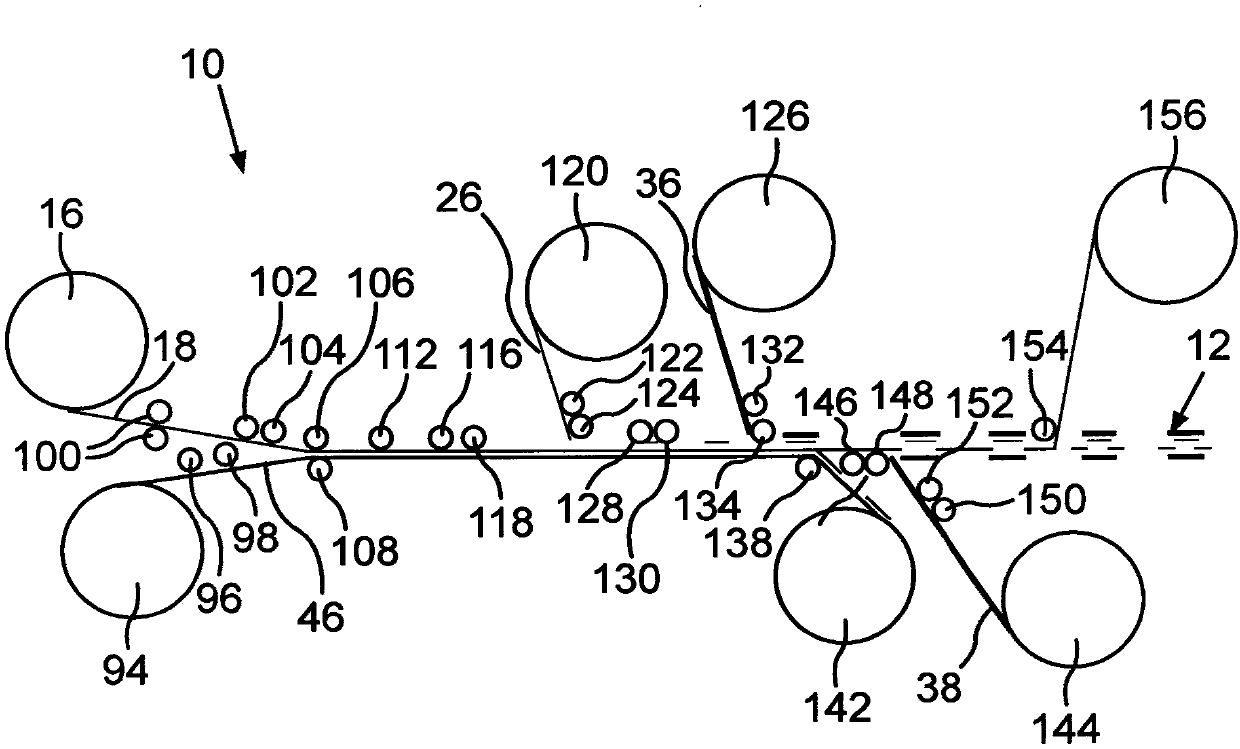

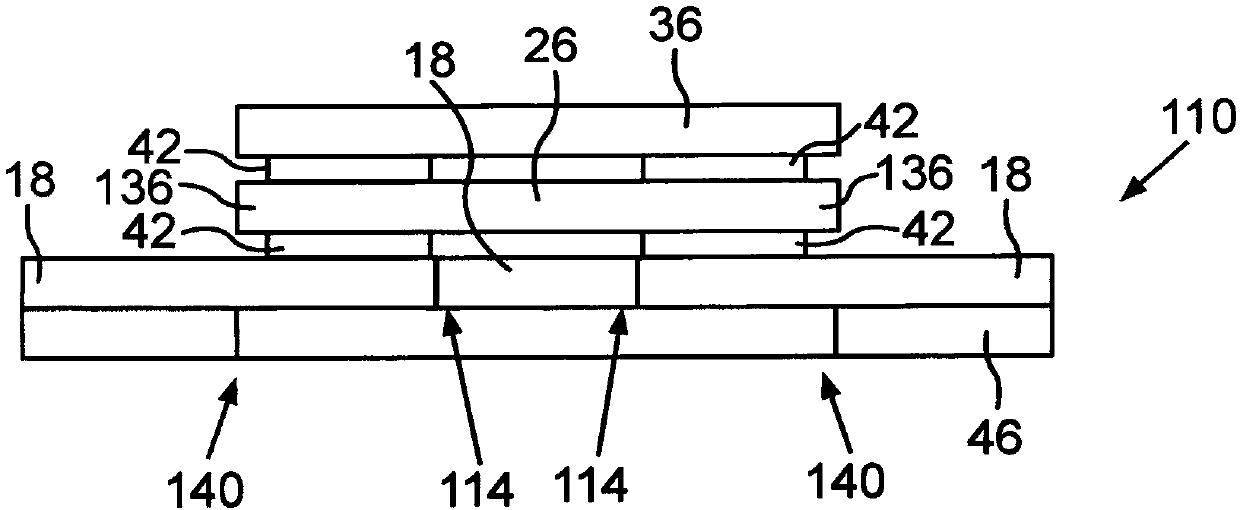

[0048] figure 1 A device 10 is shown in a greatly simplified manner for producing a membrane electrode assembly 12 with a frame 14 in a continuous production process. The printing method can be used here, or alternatively another roll processing method can be used. In this case, a continuous web-like material is unrolled from the roller 16 , by means of which the frame material 18 of the membrane-electrode assembly 12 is provided in the present invention. Correspondingly, the frame material 18 is used to form the frame 14 in the finished membrane electrode assembly 12 . In this case, the web-like material is conveyed through the device 10 in one conveying direction or feed direction. For example, a synthetic material unrolled from the roller 16 can be used as frame material 18 .

[0049] figure 1 The various processing stations traversed in the manufacture of the membrane electrode assembly 12 are shown. exist figure 1 These processing stations are only shown schematical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com