Line-to-point connection structure and transverse impulse suppression method of flux switching linear motor

A linear motor, magnetic flux switching technology, applied in biological neural network models, design optimization/simulation, special data processing applications, etc., can solve problems such as increased failure rate, increased noise, and low system transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

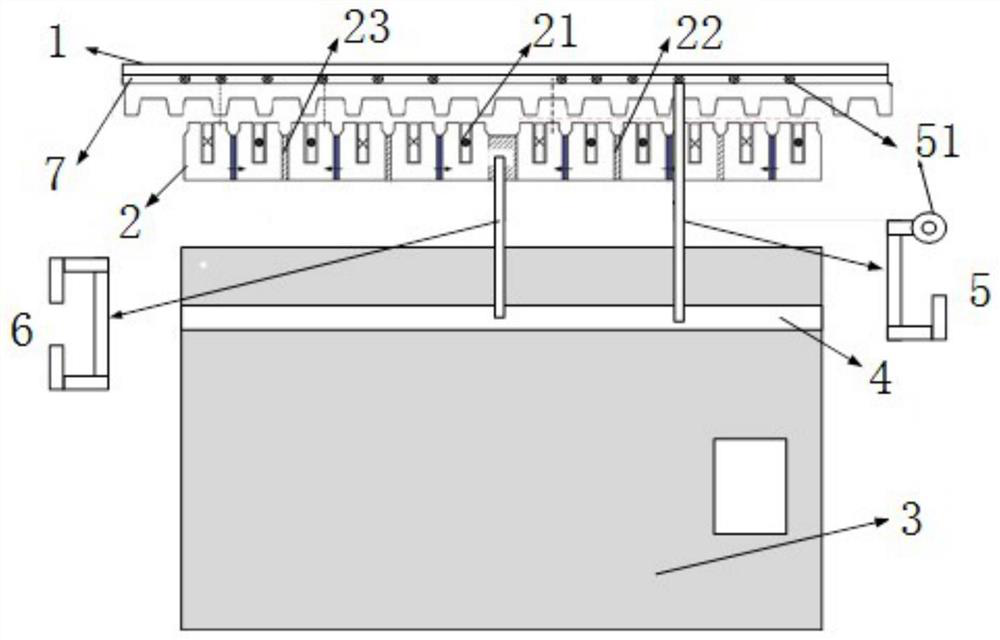

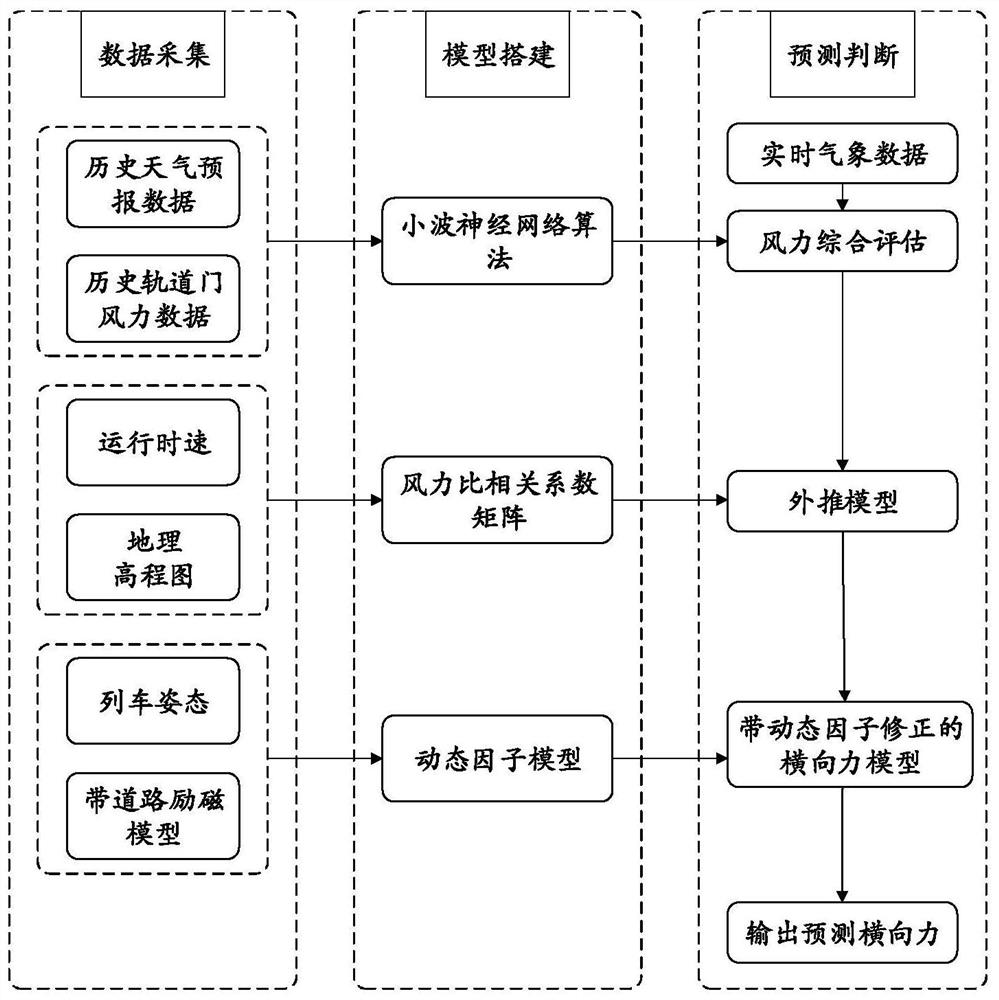

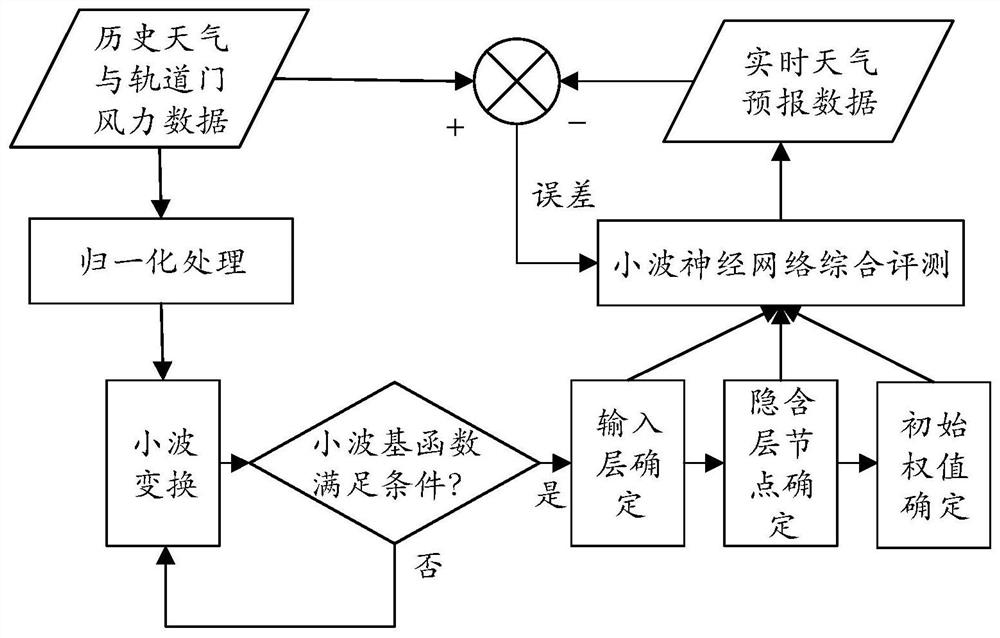

[0025] like figure 1 Shown is a line-point connection structure of a magnetic flux switching linear motor and a lateral impulse suppression method. A three-point connection is used between the LFSPM motor and the track door to ensure that the primary mover and the track are connected while the secondary stator actively carries the high load of the track door. Synchronous operation of the door; for the flux loss caused by the lateral impulse force of the track door under the conditions of train encounters and hurricanes, the digital-analog disturbance observer and the wavelet neural network algorithm are used to achieve accurate prediction of the lateral impulse force, and the reinforcement current Harmonic injection method is used to compensate, realize the lateral fixation of the track door, and reduce the loss. The invention combines a three-point fixed structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com