Double-staple stapler

A technology of a stapler and an outer frame, which is applied to staple tools, staple staple tools, manufacturing tools, etc., can solve the problem that staples reduce the formality and aesthetics of documents, waste time, and cannot stitch two staples together. and other problems to achieve the effect of improving aesthetics, simplifying workload and shortening working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

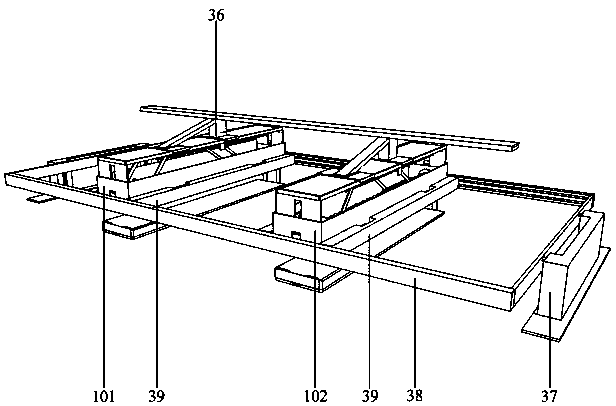

[0025] See attached figure 1 As shown, it includes a presser 36 , an outer frame base 37 , an outer frame 38 , a beam 39 , a left horizontal stapler 101 , and a right horizontal stapler 102 . The whole structure is divided into three large parts, the top pressing device, the outer frame device, and two horizontal staplers.

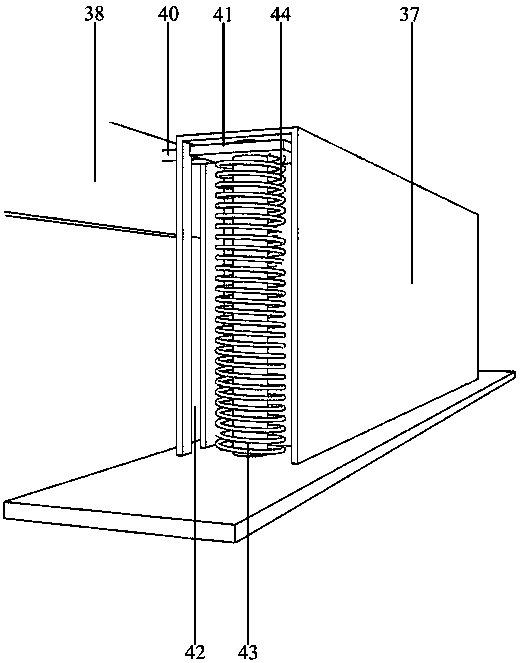

[0026] See attached figure 2As shown, it includes an outer frame base 37, an outer frame 38, an outer frame connecting rod 40, a pressure spring 41, an outer frame connecting rod sliding gap 42, a base spring axis 43, and a base spring 44. Outer frame 38 links to each other with compression reed 41 by outer frame connecting rod 40, and compression reed 41 is in outer frame base 37, and base spring 44 upper end is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com