Device for measuring fill level of liquid in container with ultrasonic sensor

A technology for ultrasonic sensors, filling levels, applications in measuring devices, material analysis using acoustic/ultrasonic/infrasonic waves, sound-generating instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

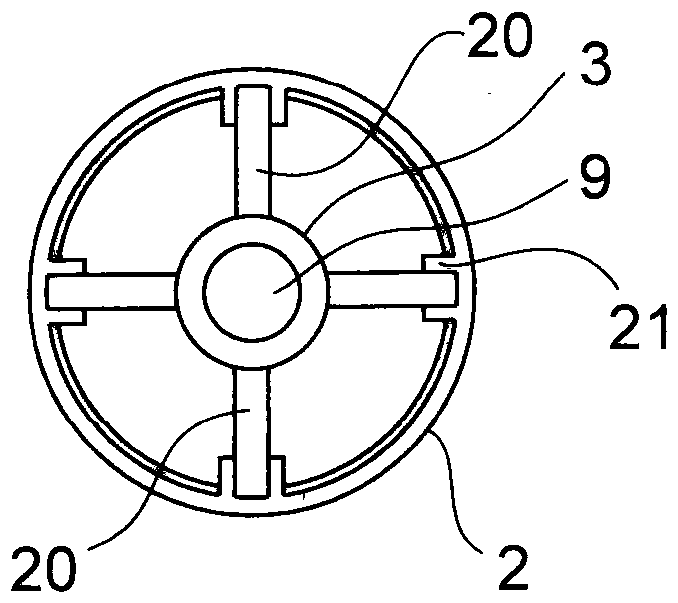

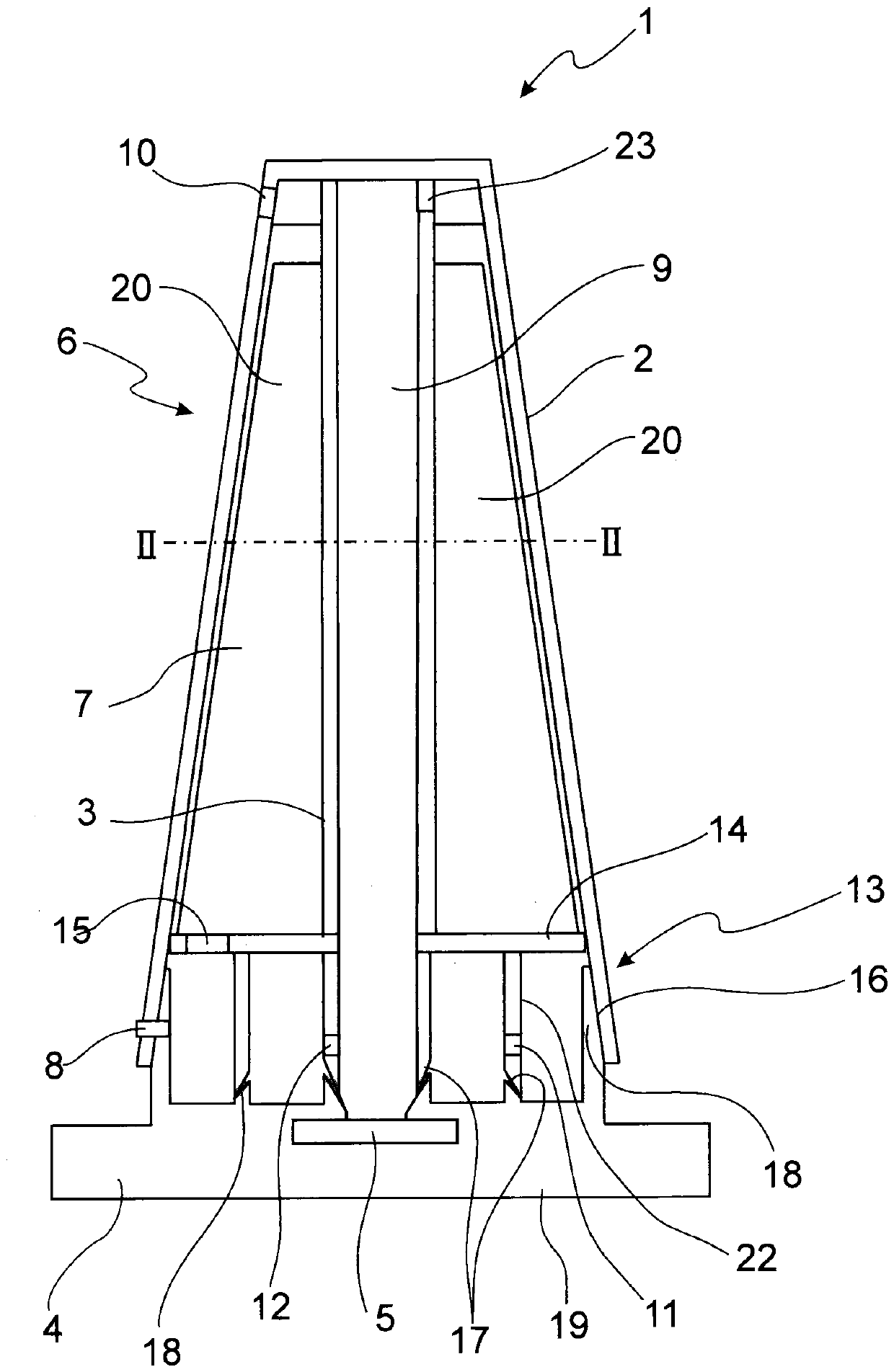

[0017] exist figure 1 The device 1 is shown in a cutaway side view. The device 1 essentially consists of a combination of a sound absorbing cup 6 and a base element 4 , which in the present embodiment is designed as a flange 19 . An ultrasonic sensor 5 is integrated in the base element 4 or arranged thereon. The base element 4 is designed here as a flange 19 , it is also evident that the flange 19 protrudes laterally beyond the structural surface of the sound absorbing cup 6 in order to form the fastening region here. A measuring tube 9 extends over the ultrasonic sensor 5 , in which measuring tube 9 the actual measurement takes place. The ultrasonic sensor 5 emits ultrasonic waves which propagate upwards in the measuring tube 9 , are reflected at the interface liquid / air and are then picked up again by the ultrasonic sensor 5 as reflected ultrasonic waves. From the travel time of the ultrasound waves, the distance of the ultrasound sensor 5 to the interface and thus the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com