Material collecting component used for filter

A filter and aggregate technology, which is applied in the direction of filtration separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of filter element tilt, mutual impact, impact on filtration efficiency, etc., to achieve convenient installation and improve filtration efficiency , no skill required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

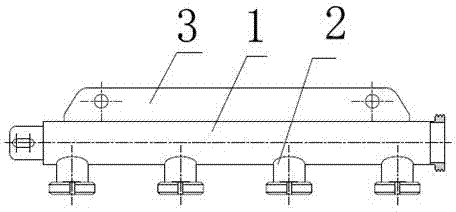

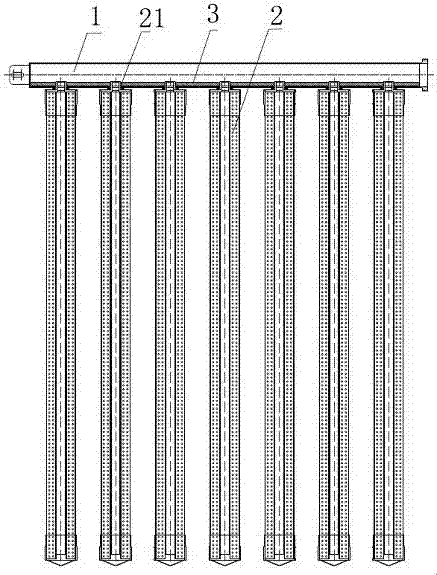

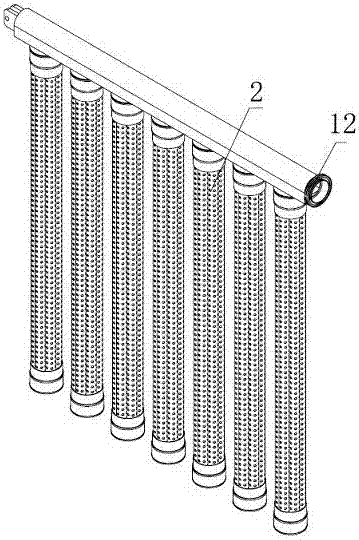

[0019] The technical scheme of the present invention is specifically set forth below in conjunction with embodiment, in conjunction with Figure 2-Figure 7 As shown, the present invention discloses a collection assembly for a filter, which, like the prior art, includes a collection pipe 1 and a filter element 2 arranged below the collection pipe 1 . Different from the welding connection in the prior art, the filter element 2 and the collecting pipe 1 are connected by threads. Specifically, the bottom of the collecting pipe 1 is a flat surface, and through holes are opened on the flat surface, and the top 11 of the collecting pipe is arched.

[0020] The bottom in the described collecting pipe is provided with a plate nut 3 equivalent to the length of the collecting pipe, and the plate nut 3 is provided with a threaded hole 31, and the threaded hole 31 is coaxial with the through hole, The upper end of the filter element 2 is provided with a threaded cap 21 , and the threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com