Cloth ironing equipment for garment production

A technology for ironing equipment and cloth, which can be used in mechanical cleaning, textile and paper making, fabric surface trimming, etc., and can solve the problems of time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

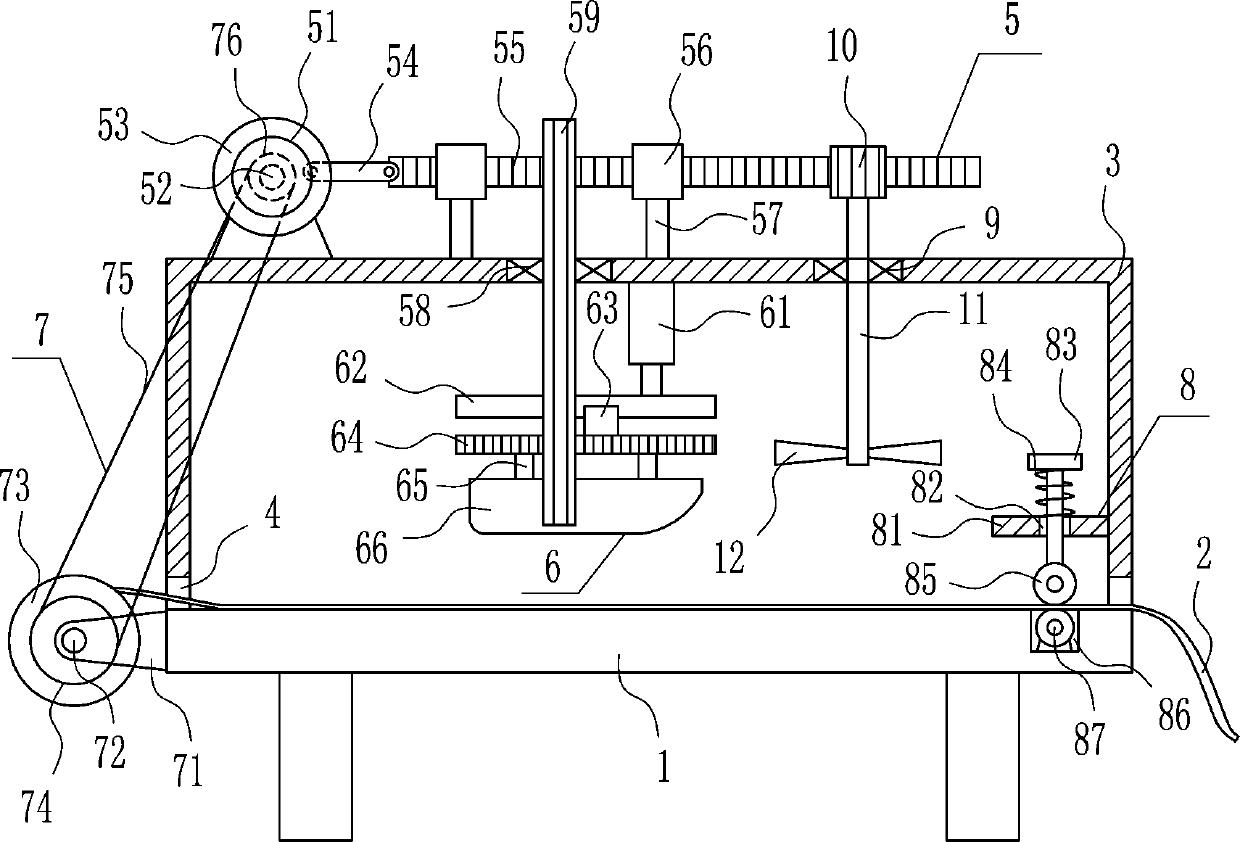

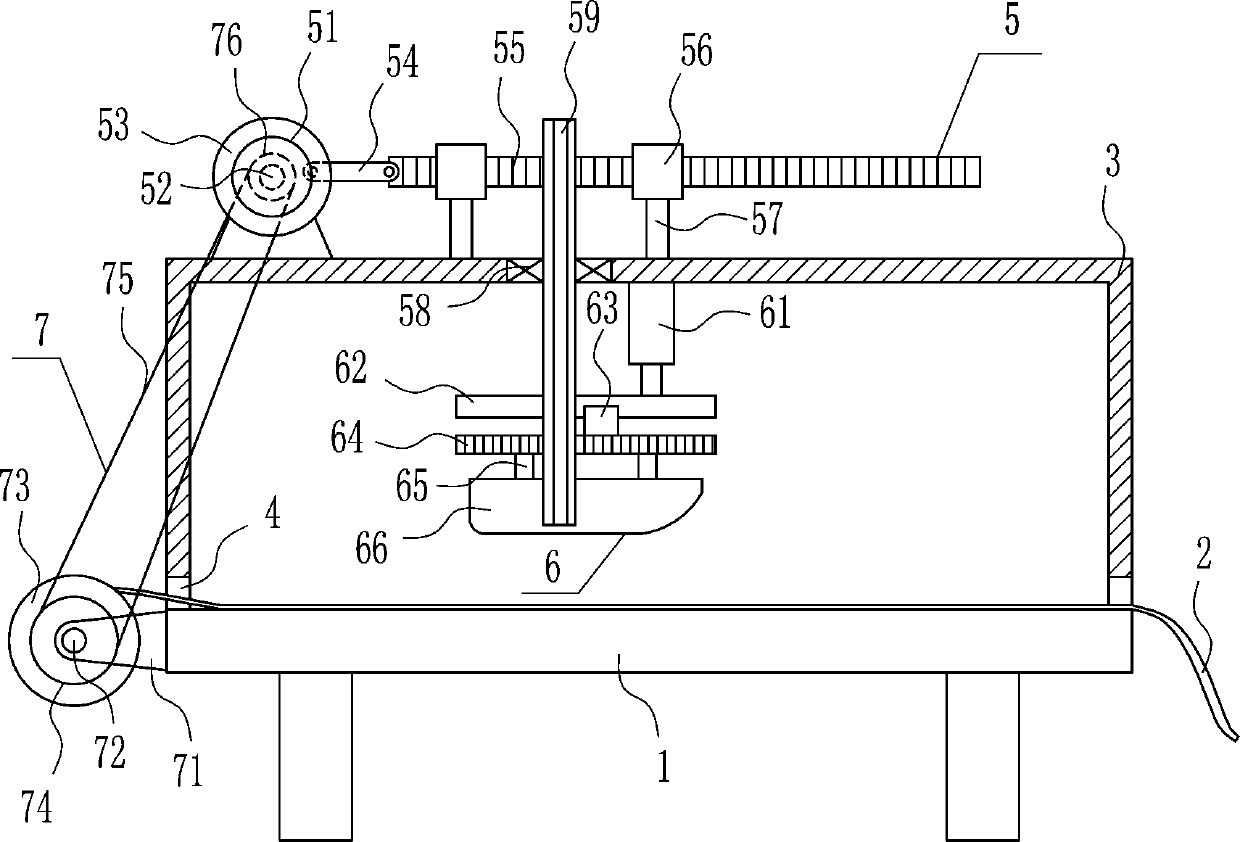

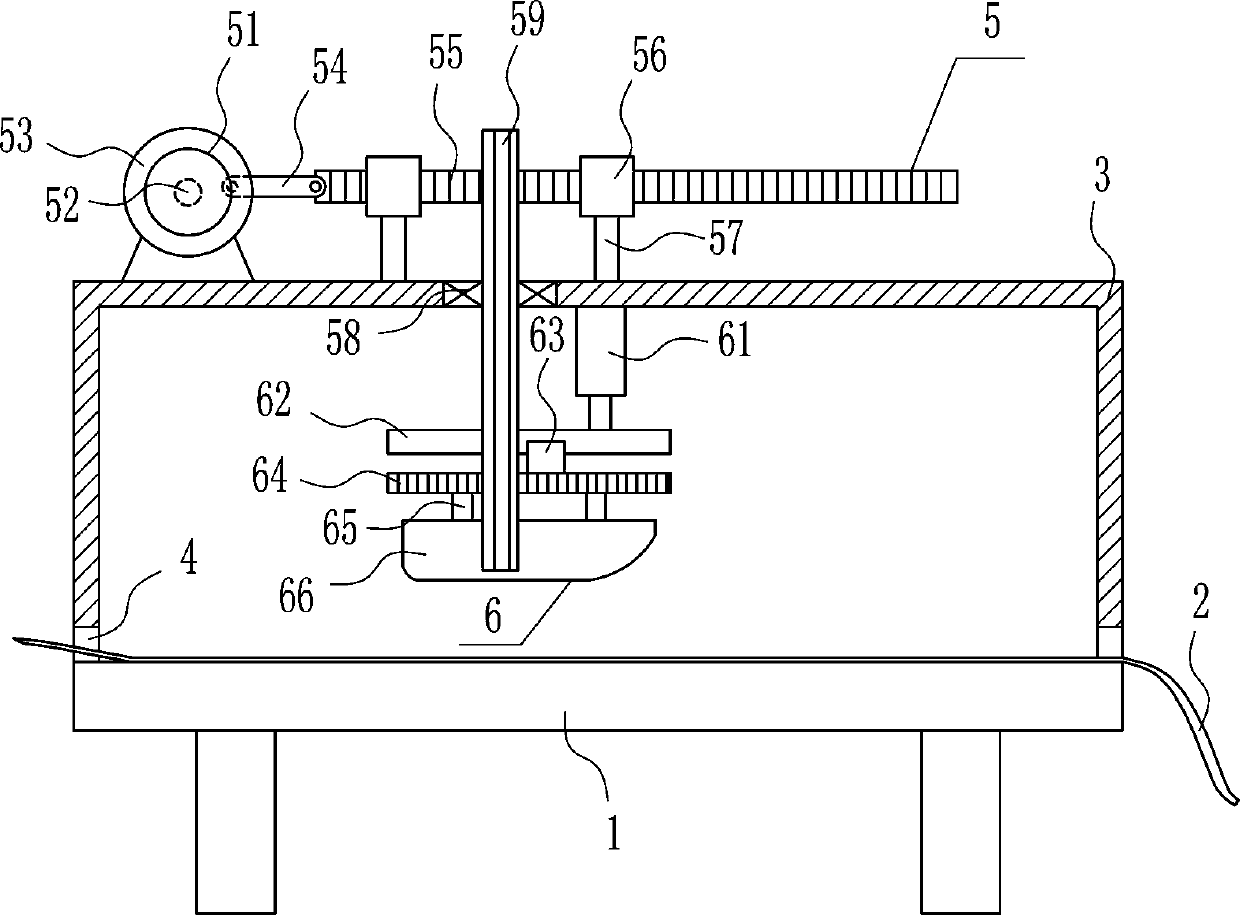

[0031] Cloth ironing equipment for garment production, such as Figure 1-5 As shown, it includes a placement table 1, a frame 3, a driving device 5 and an ironing device 6. A frame 3 is installed on the top of the placement table 1, and a through hole 4 is opened on the lower left side and the lower right side of the frame 3, and the outer top of the frame 3 A driving device 5 is arranged on the left side, and an ironing device 6 is arranged in the middle of the inner top of the frame 3 , and the ironing device 6 is in contact with the driving device 5 .

Embodiment 2

[0033] Cloth ironing equipment for garment production, such as Figure 1-5 As shown, it includes a placement table 1, a frame 3, a driving device 5 and an ironing device 6. A frame 3 is installed on the top of the placement table 1, and a through hole 4 is opened on the lower left side and the lower right side of the frame 3, and the outer top of the frame 3 A driving device 5 is arranged on the left side, and an ironing device 6 is arranged in the middle of the inner top of the frame 3 , and the ironing device 6 is in contact with the driving device 5 .

[0034] The driving device 5 includes a motor 51, a first rotating shaft 52, a disc 53, a connecting rod 54, a first rack 55, a guide sleeve 56, a pole 57, a first bearing seat 58 and a bar gear 59, and the outer top of the frame 3 The center and the left side are all equipped with poles 57, and the tops of the two poles 57 are equipped with guide sleeves 56. A first tooth bar 55 is arranged between the guide sleeves 56 on th...

Embodiment 3

[0036] Cloth ironing equipment for garment production, such as Figure 1-5 As shown, it includes a placement table 1, a frame 3, a driving device 5 and an ironing device 6. A frame 3 is installed on the top of the placement table 1, and a through hole 4 is opened on the lower left side and the lower right side of the frame 3, and the outer top of the frame 3 A driving device 5 is arranged on the left side, and an ironing device 6 is arranged in the middle of the inner top of the frame 3 , and the ironing device 6 is in contact with the driving device 5 .

[0037] The driving device 5 includes a motor 51, a first rotating shaft 52, a disc 53, a connecting rod 54, a first rack 55, a guide sleeve 56, a pole 57, a first bearing seat 58 and a bar gear 59, and the outer top of the frame 3 The center and the left side are all equipped with poles 57, and the tops of the two poles 57 are equipped with guide sleeves 56. A first tooth bar 55 is arranged between the guide sleeves 56 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com