A multifunctional cutting machine

A cutting machine, multi-functional technology, applied in the cutting of textile materials, fabric surface trimming, textiles and papermaking, etc., can solve the problems of heavy workload, inaccurate cutting of manual line drawing, etc., to improve production efficiency, reduce deformation, The effect of avoiding traces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

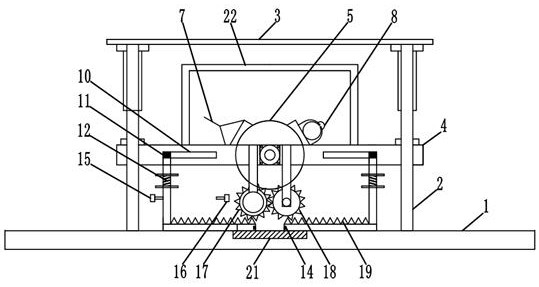

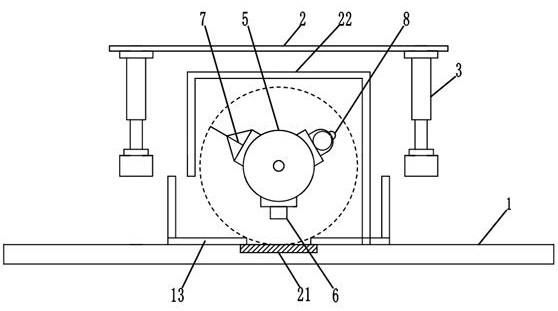

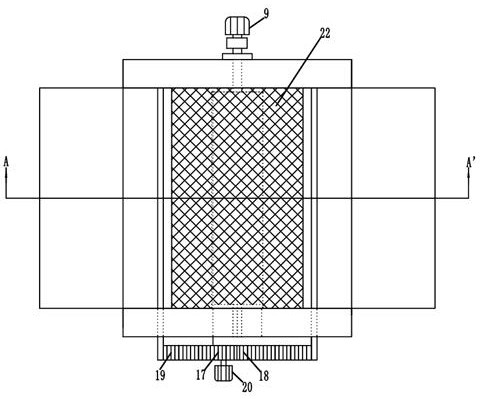

[0026] Such as Figure 1-3 As shown, a multifunctional cutting machine includes a workbench 1, a support frame 2 is fixed on the workbench 1, and a hydraulic rod 3 is fixed upside down on the bottom surface of the top of the support frame 2, and the hydraulic rod 3 is connected with a hydraulic pump station, There is an operation button for controlling the expansion and contraction of the hydraulic rod 3; a set of beams 4 are connected under the hydraulic rod 3, and the beam 4 is provided with a bearing seat in the middle position. The shaft at one end of the drum 5 is connected to the bearing seat, and the shaft at the other end of the drum 5 penetrates The bearing seat on the beam 4 is connected to the first stepping motor 9 through a coupling. The first stepping motor 9 provides power for the rotation of the drum 5; the surface of the drum 5 is provided with a laser marking device 6 at the center position. The preferred model of the marking device 6 is LTA200L-30. The length...

Embodiment 2

[0028] The working method of a multifunctional cutting machine is as follows: When the cloth needs to be cut, the operator fully unfolds the cloth on the worktable 1 and keeps it flat, the drum 5 is in the initial position, and the laser marker 6 is at the bottom, and the laser is turned on The switch of the marking device 6, the marking line of the laser marking device 6 is projected on the cloth, the operator can adjust the cloth according to the cutting size, and after the adjustment is correct, the first stepping motor 9 is started, and the first stepping motor 9 drives the drum 5 to rotate After the drum 5 rotates 120°, the cutter 7 moves to the lowermost position and is tangent to the reinforcement block 21 on the worktable 1 to complete the cutting of the cloth; the drum 5 continues to rotate until the atomizing nozzle 8 reaches the bottom, and then the control The controller stops the rotation of the first stepping motor 9 and starts the water pump at the same time. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com