A kind of forming method of vertical coaming plate of electrolytic cell

A molding method and electrolytic cell technology are applied in the field of manufacturing process of vertical shrouds of electrolytic cell shells, which can solve the problems of low forming efficiency, low rounding precision, poor appearance quality, etc., so as to solve the problems of low efficiency and realize batch forming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific engineering example, further elaborate the present invention. The specific steps are:

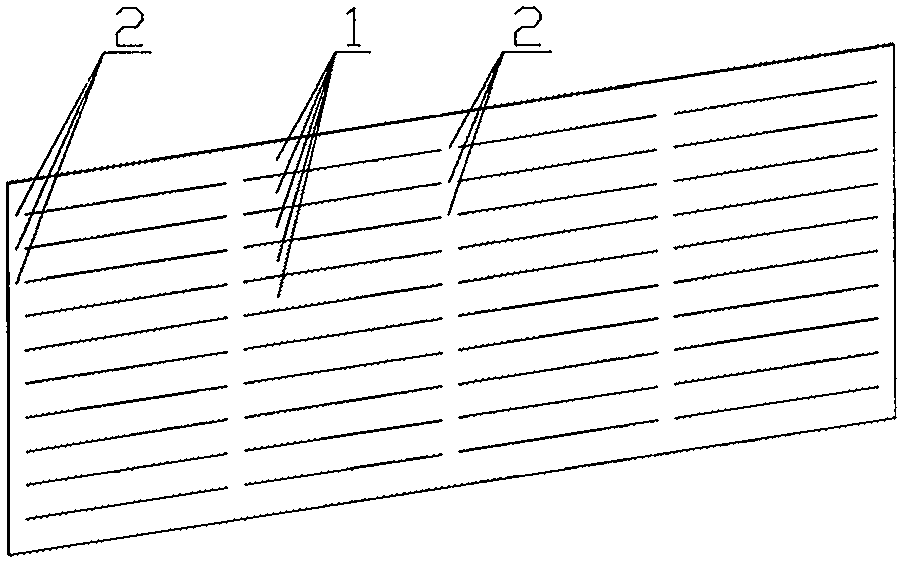

[0019] (1) The overall blanking and cutting of multiple vertical hoarding parts, such as figure 1 . Cut multiple strips 1 of vertical hoarding parts at the same time by intermittent cutting on the steel plate, leave 100mm connecting section 2 at both ends of each panel without cutting, and leave 3-4 100mm long connecting sections 2 at equal intervals in the middle part without cutting .

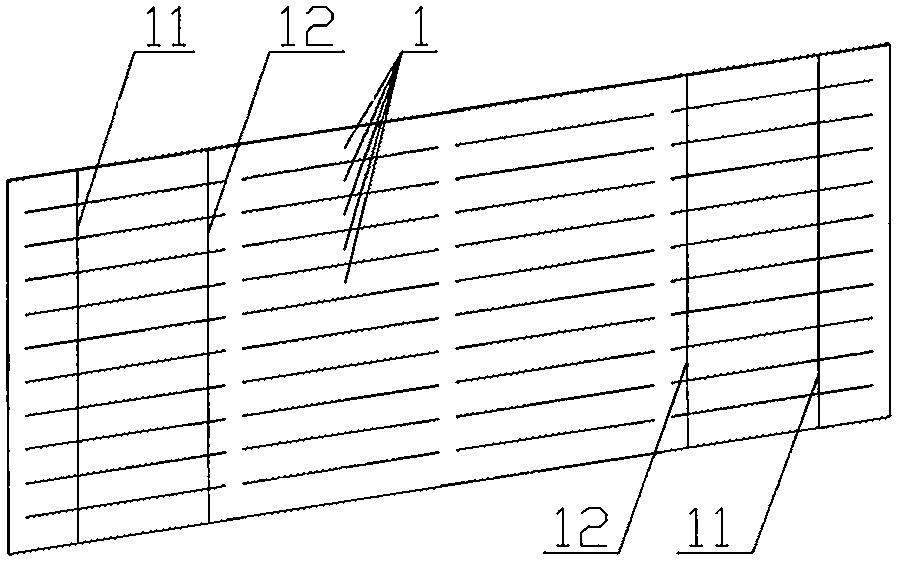

[0020] (2) underline, such as figure 2 . Draw the starting line 11 and the ending line 12 of the arc section of the vertical wall on the steel plate, and the starting line 11 and the ending line 12 of the arc section must be perpendicular to the long side of the vertical wall part slat 1.

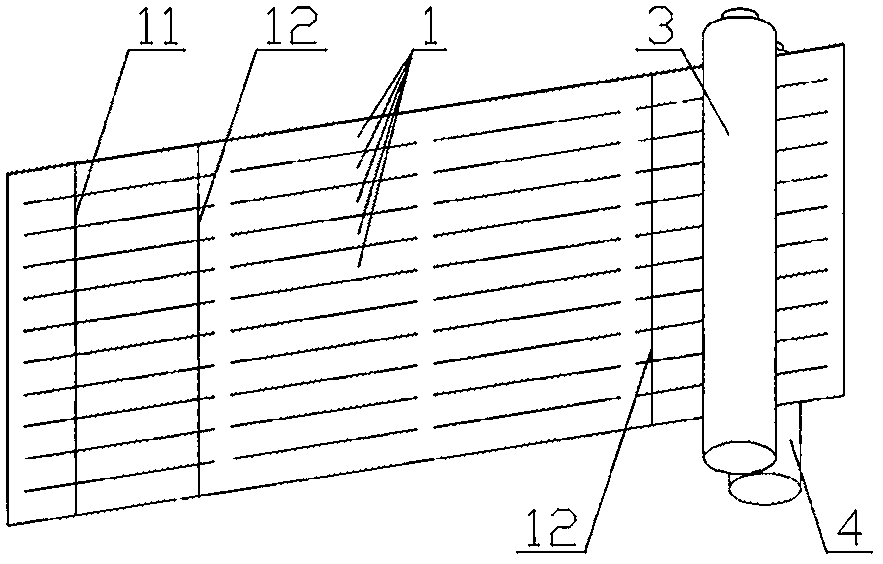

[0021] (3) into an arc, such as image 3 and Figure 4 . A small-diameter two-roll plate rolling machine is used for rolling and forming. Firstly, the arc on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com