Lotus-root beam unit connected with prefabricated floor slab unit and three-dimensional beam-column unit

A three-dimensional beam column and floor slab technology, applied to floors, building components, buildings, etc., can solve problems such as increased installation difficulty and transportation difficulties, and achieve the effects of improving prefabrication rate, saving social resources, and realizing seismic isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

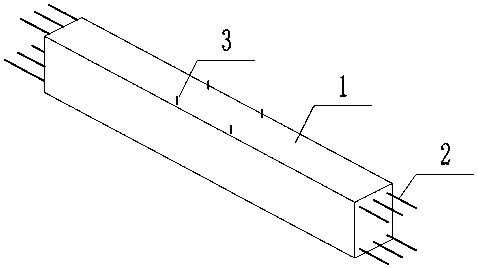

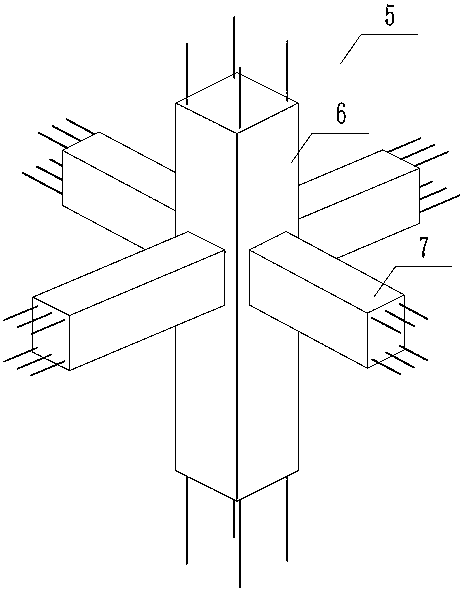

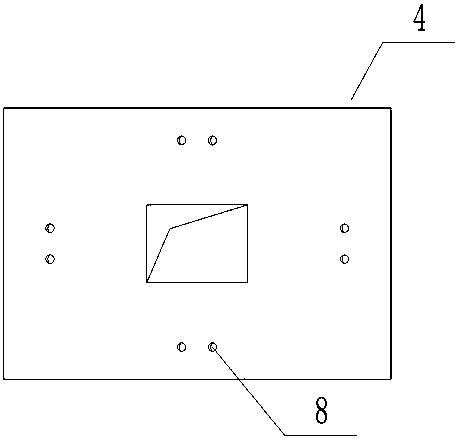

[0019] 1. A lotus root beam unit connected with the prefabricated floor unit 4 and the three-dimensional beam-column unit 5, including the lotus root beam body 1, the reinforcement material 2, the embedded part 3, and the reinforcement material 2 can pass through the sleeve and the three-dimensional beam-column unit 5 The beam unit 7 is connected with reinforcement, and then concrete is poured, and the embedded part 3 can install the prefabricated floor unit 4 in place through the plate-beam installation hole 8 in the prefabricated floor unit 4 (such as figure 1 , figure 2 , image 3 ). The lotus root beam body 1 is prefabricated concrete.

[0020] 2. A lotus root beam unit connected with the prefabricated floor unit 4 and the three-dimensional beam-column unit 5, including the lotus root beam body 1, the reinforcement material 2, the e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap