A planting robot control system

A technology of control system and robot, which is applied to the parts of planters, hole planters, and sowing, can solve the problems of low degree of mechanization, influence on seedling emergence rate, complex equipment, etc., achieve high degree of automation, increase planting efficiency and quality, The effect of simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

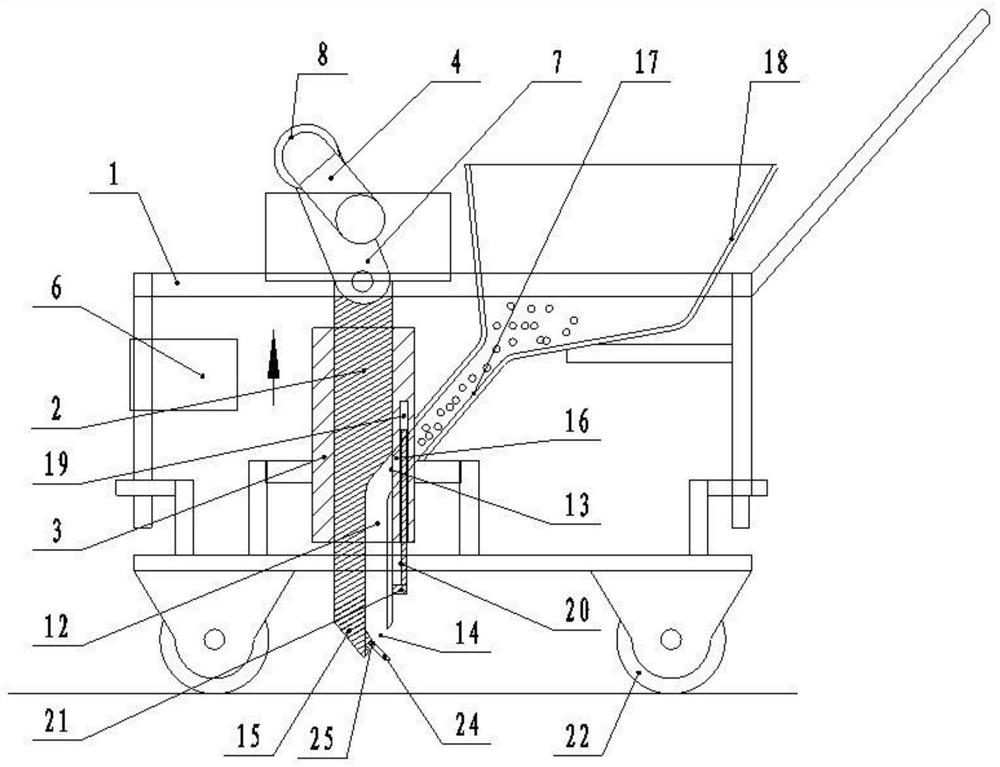

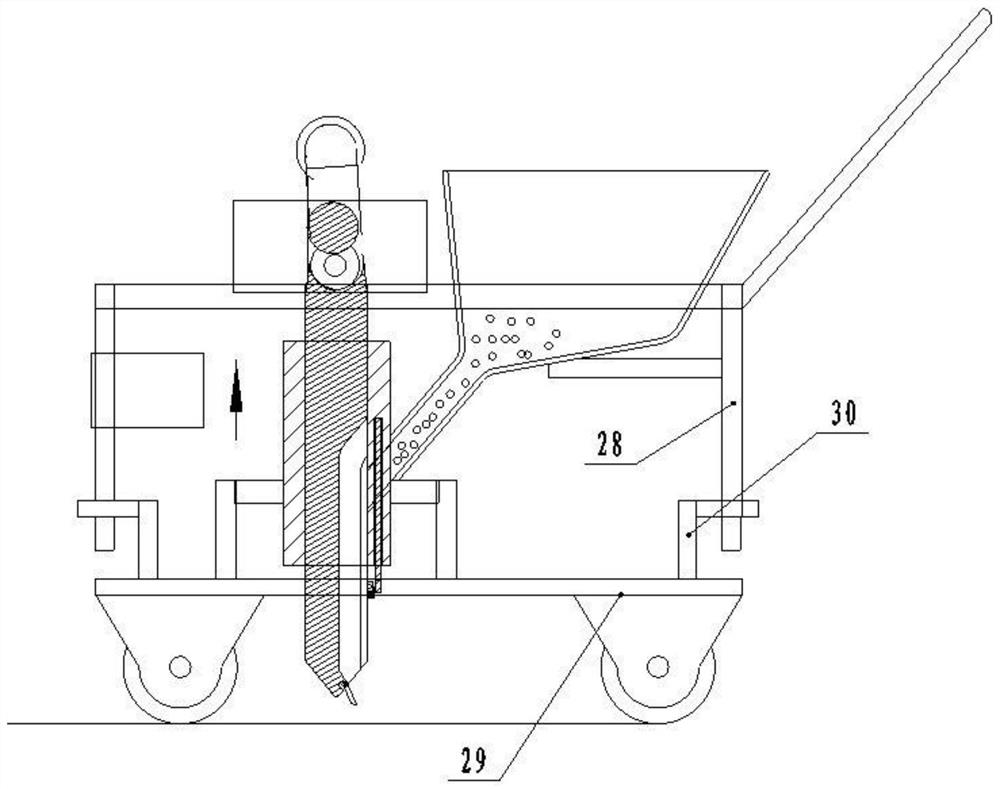

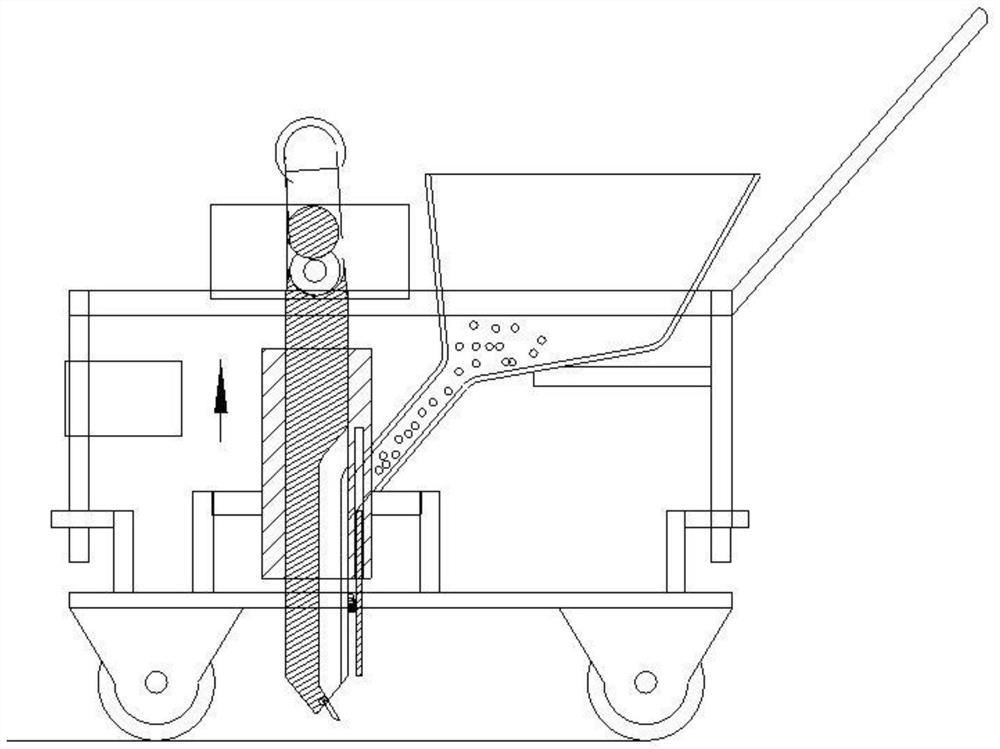

[0040] Such as Figure 1-8 As shown, a planting robot control system of the present invention includes a lifting sowing cone rod 2 and a controller 23, the controller 23 controls the operating speed of the electric hub 22 and the rotating speed of the motor 5, and the controller 23 controls the electric hub 22 pulse type advances to determine the sowing distance of two nests of seeds or seedlings; the controller 23 performs the sowing operation by controlling the rotation of the motor 5;

[0041] By starting the controller 23 switch, the electric wheel hub 22 drives forward, and the motor 5 drives the rotating gear 9 to rotate through the motor gear 11 on the rotating shaft 10, and the rotating gear 9 drives the crankshaft 4 to rotate, and the crankshaft 4 passes through the connecting rod crank neck 8 and the connecting rod. 7 Drive the lifting and planting cone rod 2 to reciprocate up and down;

[0042] The rotation of the motor 5 is controlled by the controller 23. During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com