a planting robot

A robot and seeding channel technology, applied in the directions of planter parts, hole planting planters, and sowing, can solve the problems of low degree of mechanization, affecting the emergence rate, wasting seeds, etc., achieving a high degree of automation, improving planting efficiency and quality, The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

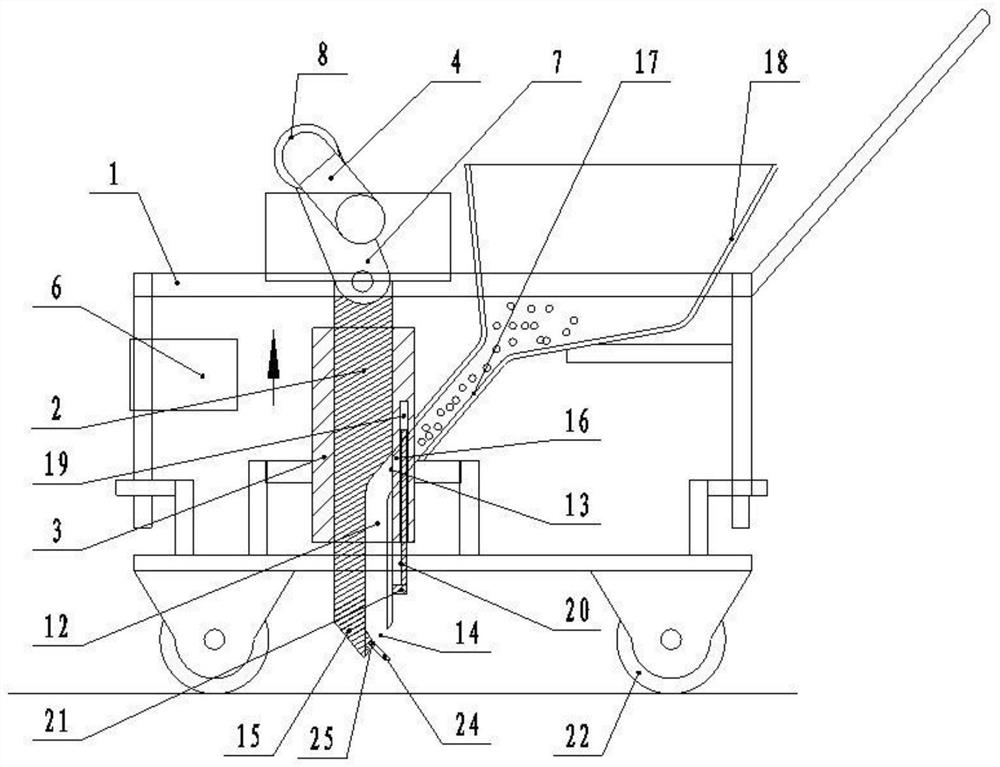

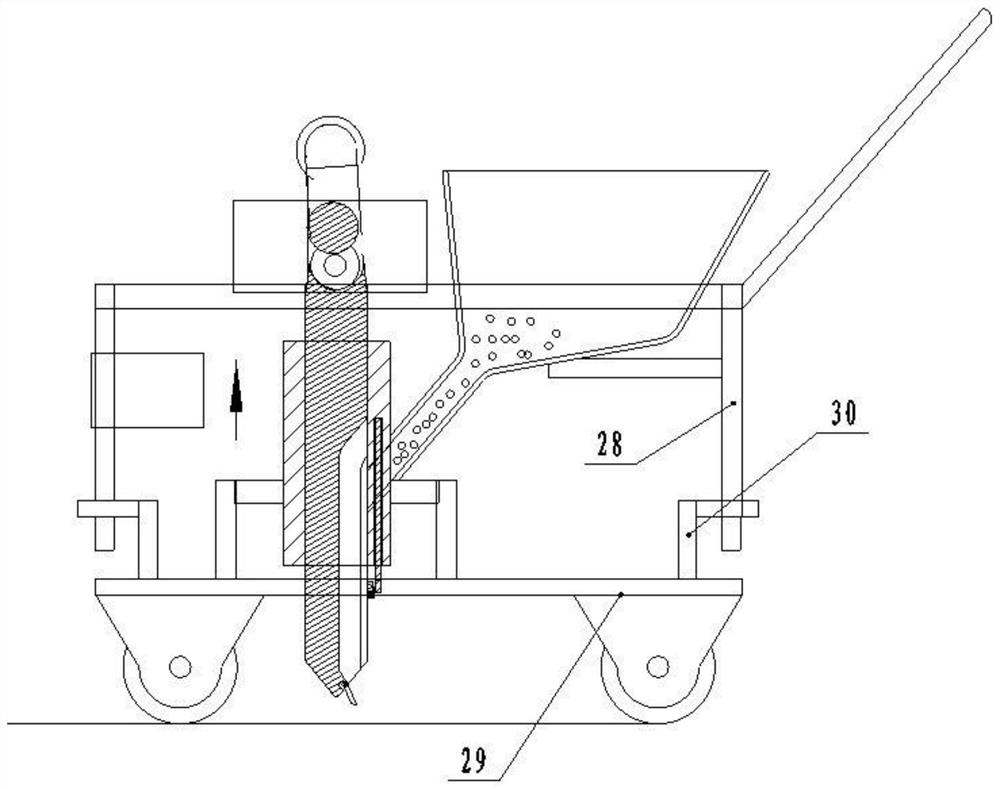

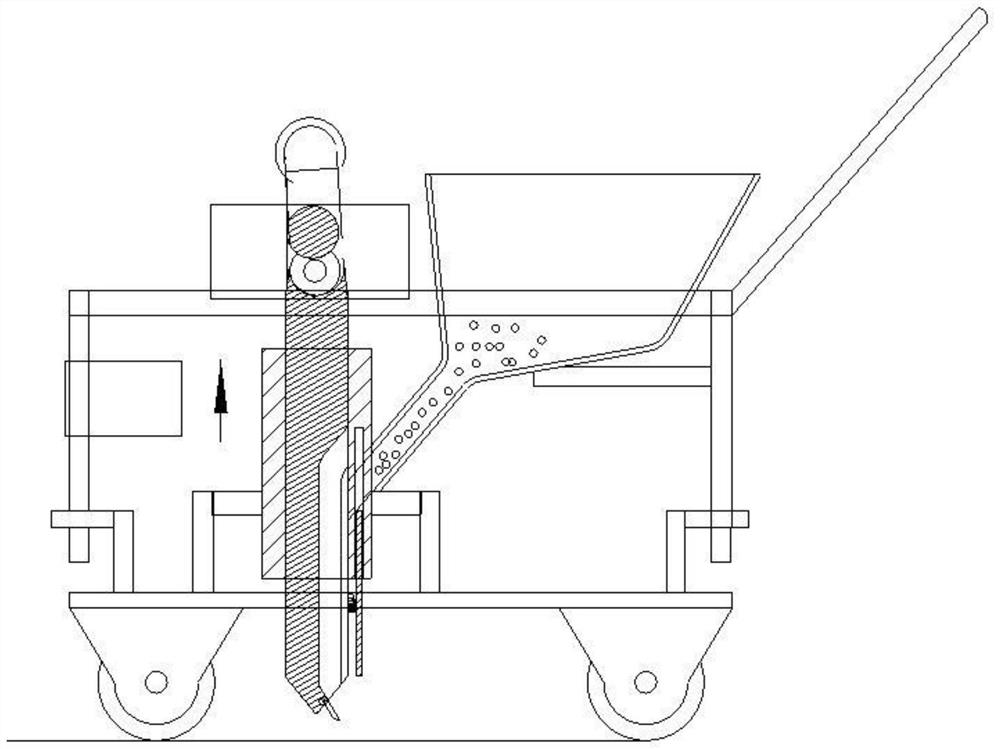

[0035] like Figure 1-8 As shown, a seeding robot of the present invention includes a frame 1, a lifting and lowering seeding cone 2, a limit sleeve 3, a crankshaft 4, a motor 5 and a battery 6, and the limit sleeve 3 is fixedly arranged in the frame 1. The seeding taper rod 2 is inserted into the limiting sleeve 3, and the upper end of the lifting seeding taper rod 2 is connected to the connecting rod crank neck 8 of the crankshaft 4 through the connecting rod 7, and the crankshaft 4 is provided with a rotating gear 9, the said The rotating shaft 10 of the motor 5 is provided with a motor gear 11 , and the motor gear 11 is in meshing transmission connection with the rotating gear 9 , and the motor 5 is connected with the battery 6 .

[0036] There is a seeding channel 12 in the lower part of the lifting seeding cone 2. The upper end of the seeding channel 12 is the seeding inlet 13, which is arranged on the middle rod wall of the lifting seeding cone 2. The lower end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com