Heat treatment method for economical copper-containing antibacterial stainless steel hot rolled plate

A technology of antibacterial stainless steel and heat treatment method, which is applied in the field of heat treatment of copper-containing antibacterial stainless steel hot-rolled sheets, can solve problems such as increasing cost and increasing production processes, and achieves the effect of good antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

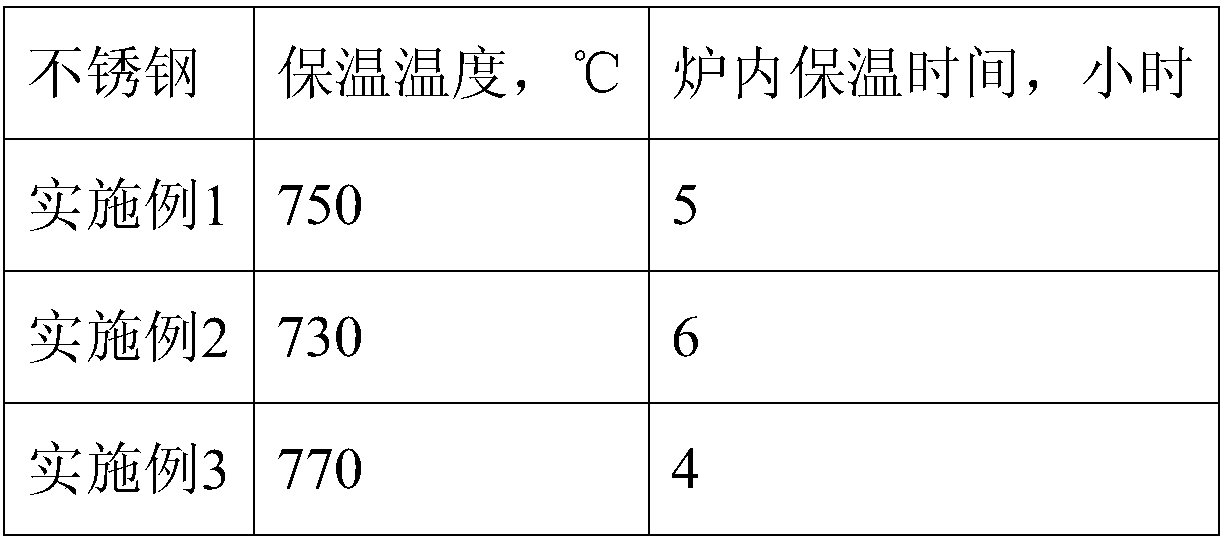

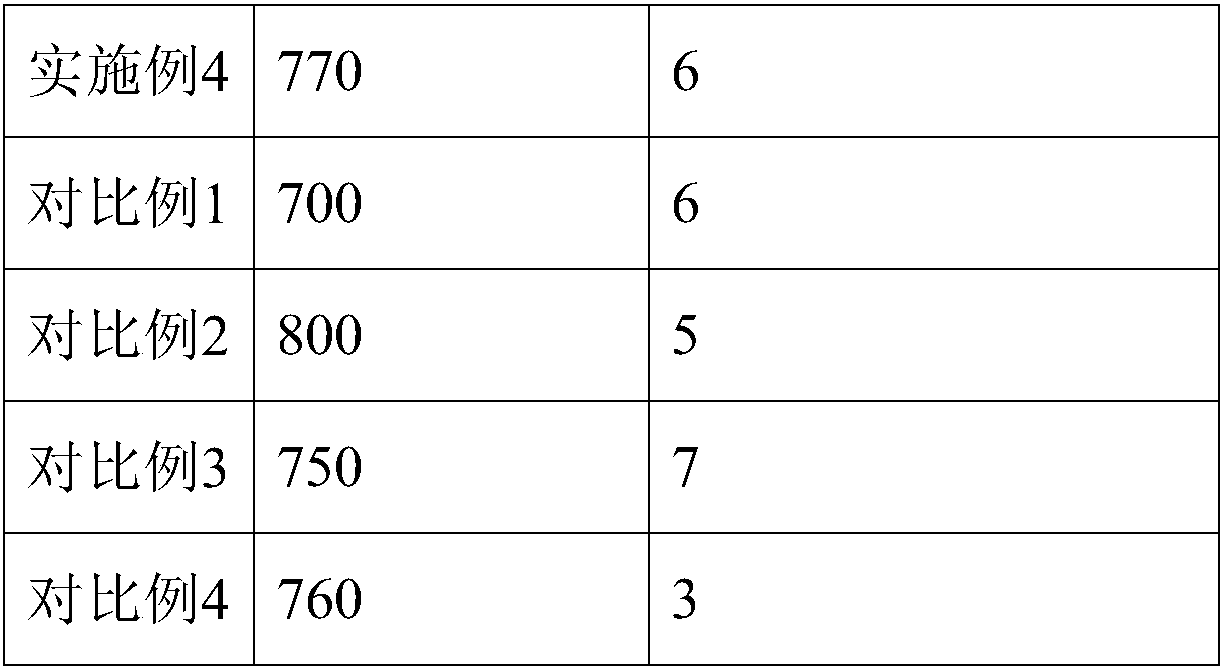

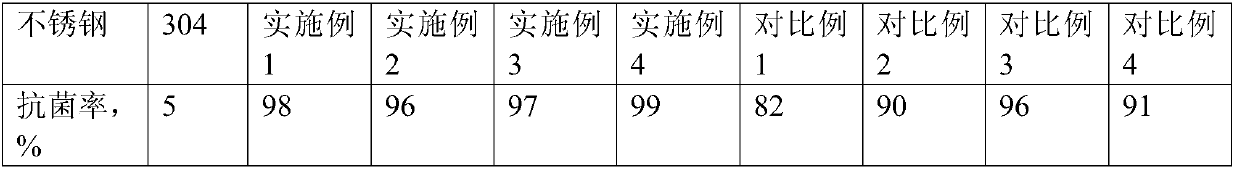

[0018] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the heat treatment method of an economical copper-containing antibacterial stainless steel hot-rolled plate proposed by the present invention will be described in detail below in conjunction with the examples and comparative examples. Wherein the embodiment and the comparative example adopt the same plate thickness (12mm) and the hot-rolled sheet material of identical chemical composition, the chemical composition of material by weight percentage is: C: 0.02%; Si: 0.2%; Mn: 0.2%; S: 0.002%; P: 0.008%; Ni: 8.1%; Cr: 18.3%; Cu: 5.2%;

[0019] The heat treatment step of the hot-rolled plate comprises:

[0020] Step 1. Transfer the copper-containing antibacterial stainless steel plate after final rolling at 900°C to the holding furnace to cool with the furnace, and set the temperature of the holding furnace to different temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com