Bending transportation type ceramic conveying production line

A technology for conveying lines and ceramics, applied in the field of curved conveying ceramic conveying production lines, can solve the problems of inability to realize bending and steering transportation, and achieve the effects of stable and reliable transportation process, good performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

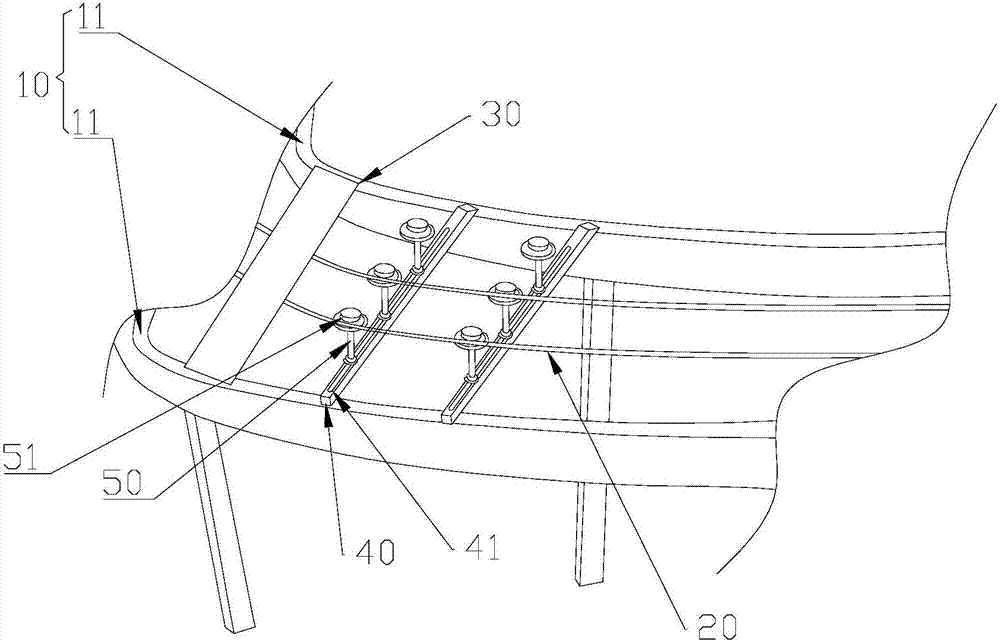

[0016] refer to figure 1 , a curved transportation type ceramics transportation production line, the curved transportation type ceramics transportation production line includes a curve 10 and a conveyor line 20, the outer curve of the curve 10 is higher than the inner curve, and the conveyor line 20 is arranged on the curve Road 10 is used to transport ceramics 30, so the design of the curve of this technical solution, because the outer curve is higher than the inner curve, so when the conveyor line transports ceramics on the curve, due to the effect of centripetal force, the ceramics will be bent and transported along the curve, The technical solution not only has simple structure, good performance, and stable and reliable transportation process, but also brings great convenience to manufacturers in the ceramic transportation process, and satisfies multiple demands of manufacturers well.

[0017] Preferably, the bend 10 includes two oppositely distributed support frames 11, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com