A flip tool for rat assembly

A technology for flipping tooling and mounting seats, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of laborious, time-consuming assembly and testing, low efficiency, etc., and achieve the effect of simple use method, simple structure and convenient maintenance of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

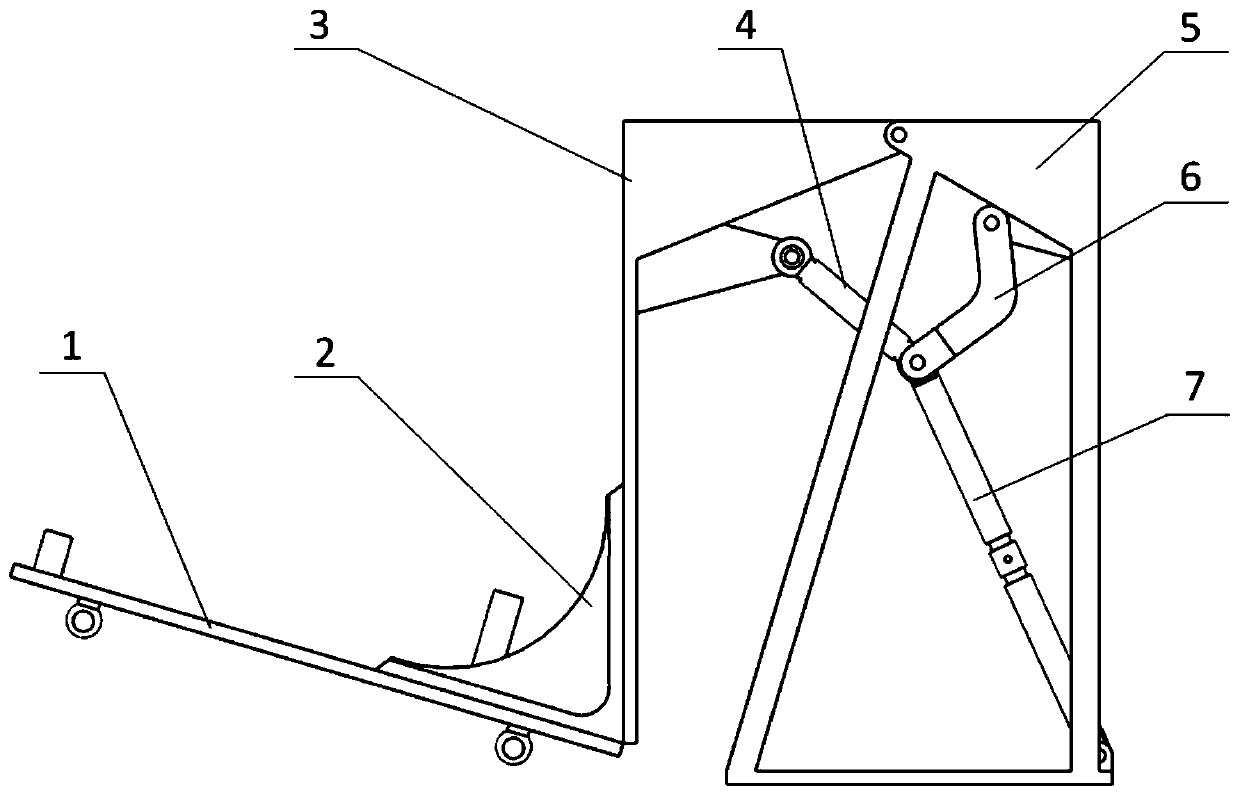

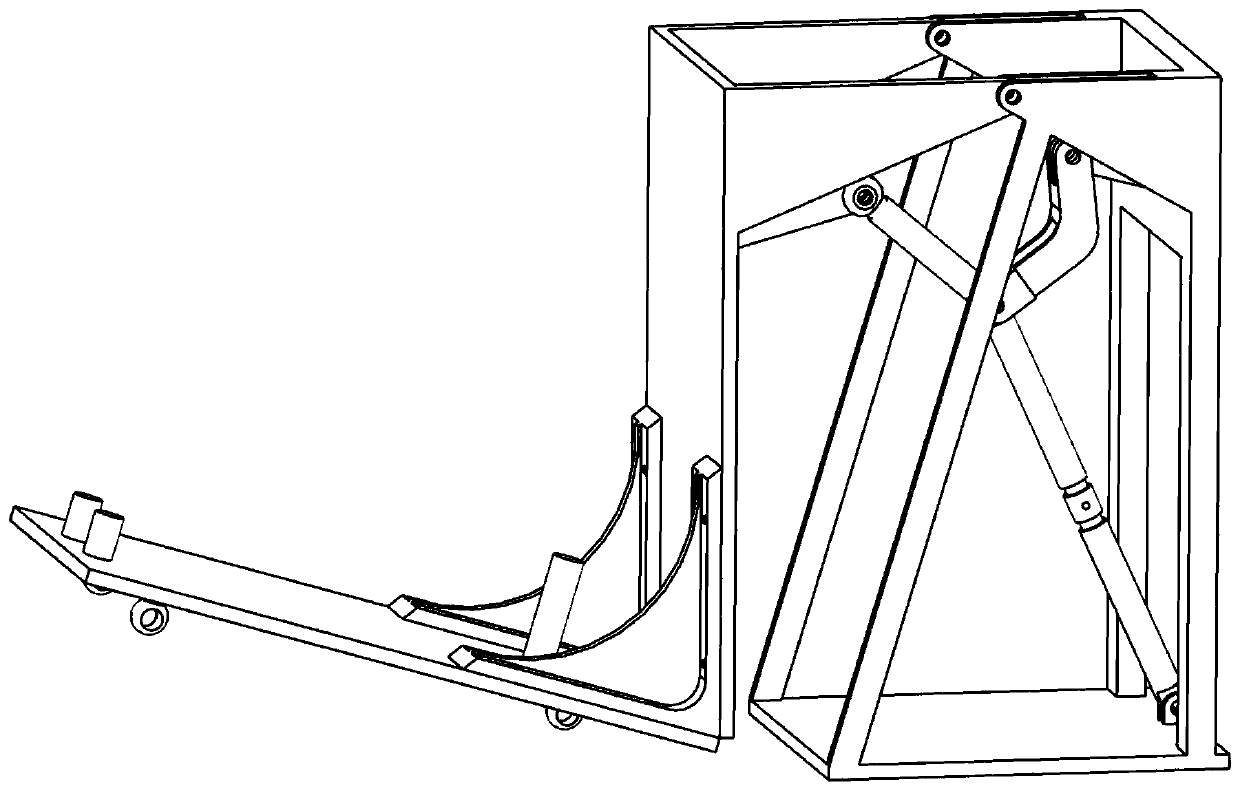

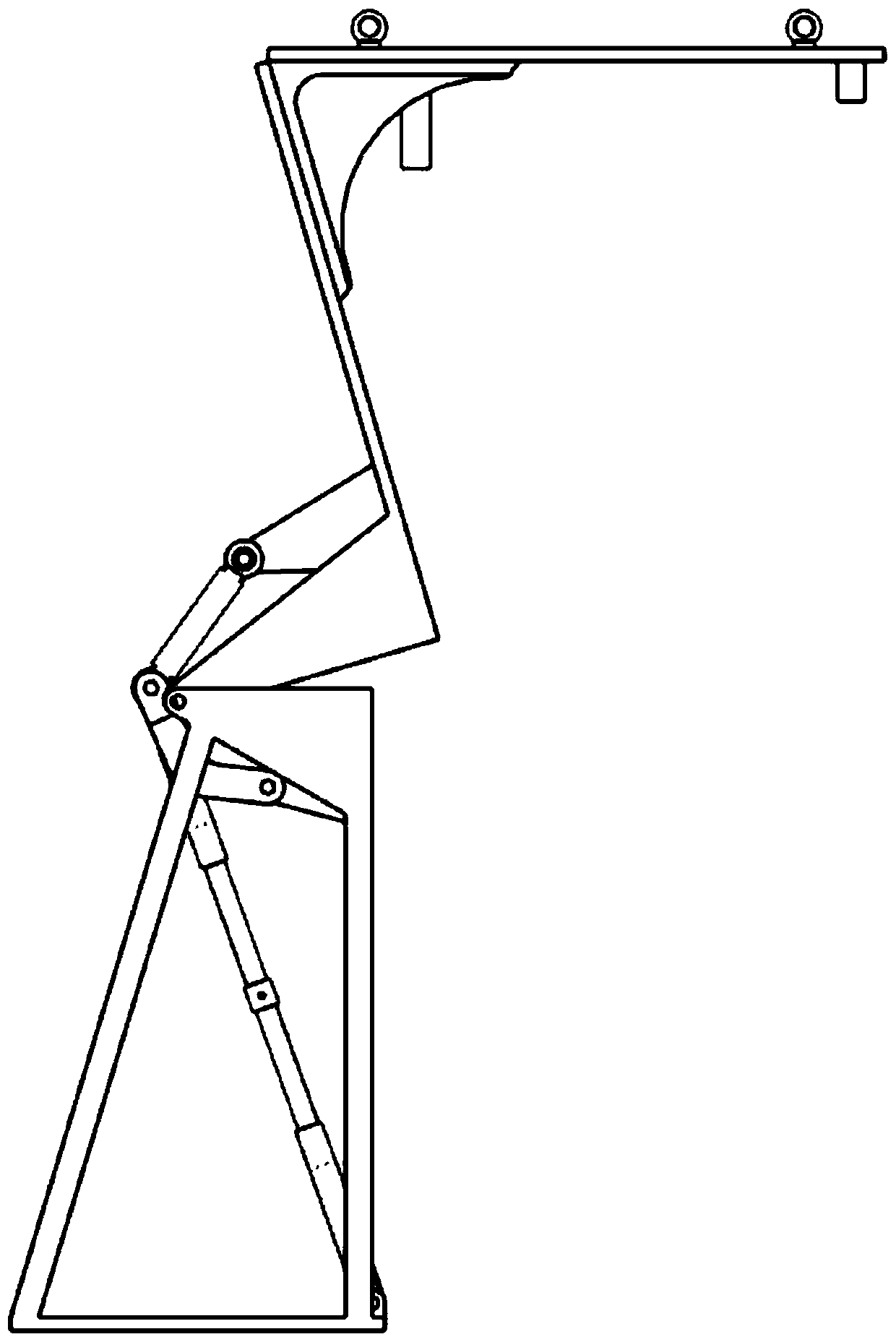

[0014] A flipping tool for RAT assembly, including an assembly mounting seat 1, an adapter seat 2, a rotating arm 3, a connecting rod 4, a base 5, a crank connecting rod 6, and a threaded adjustment rod 7, wherein the assembly mounting seat 1 and the adapter seat 2 and the rotating arm 3 are connected by bolts to form a rigid body, which forms a single-degree-of-freedom four-bar linkage together with the connecting rod 4, the crank connecting rod 6 and the threaded adjustment rod 7, and one end of the threaded adjustment rod 7 is connected to the base 5 is hinged, and the other end is hinged with connecting rod 4 and crank connecting rod 6 to form two revolving pairs. The other end of connecting rod 4 is hinged with rotating arm 3, and rotating arm 3 and crank connecting rod 6 are respectively hinged with base 5. Fixed on the ground, the RAT is assembled in an inverted posture on the assembly mount 1. After the assembly is completed, the length of the threaded adjustment rod 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com