Simple cutting device for small corrugated machine

A technology of cutting device and corrugating machine, which is applied in the field of corrugating machines, can solve the problems of no cutting device, unfavorable storage of corrugated paper, damage of corrugated paper, etc., and achieve the effect of low cost, easy inspection and repair, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

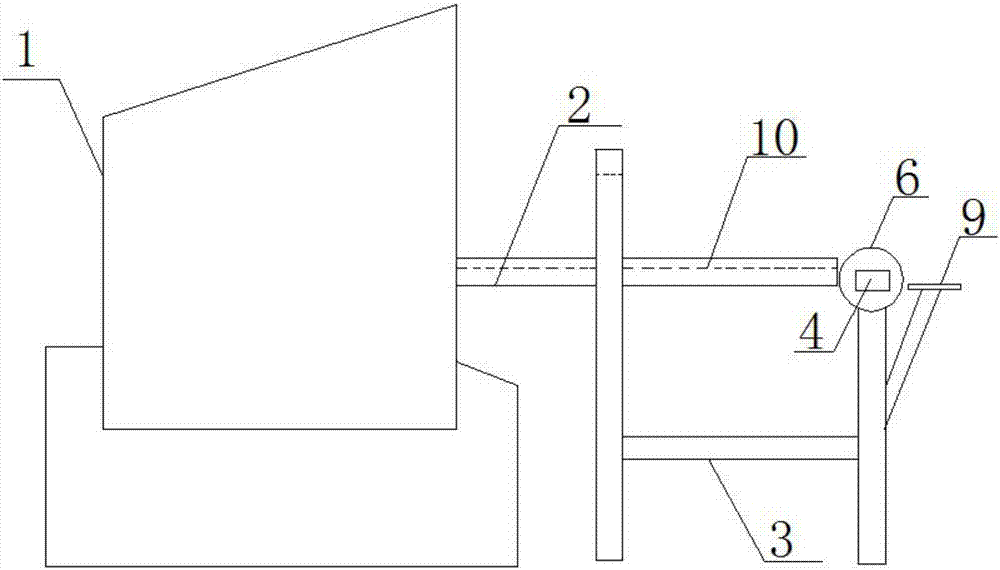

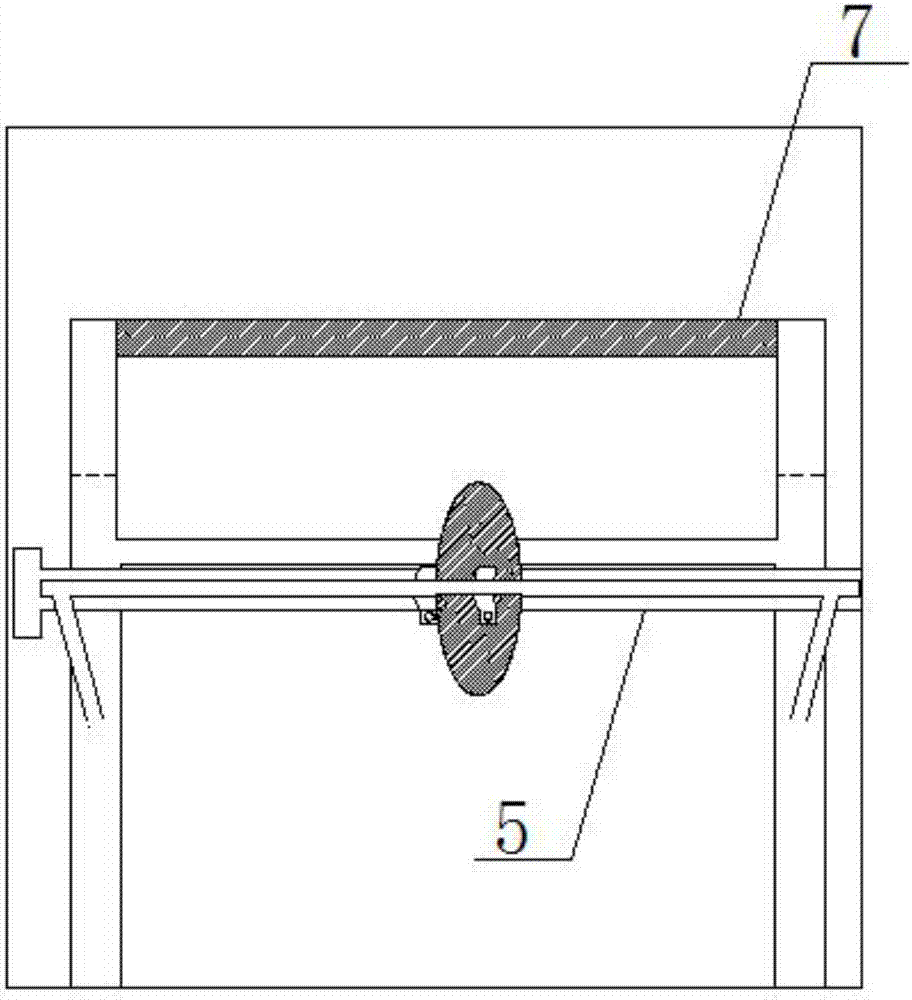

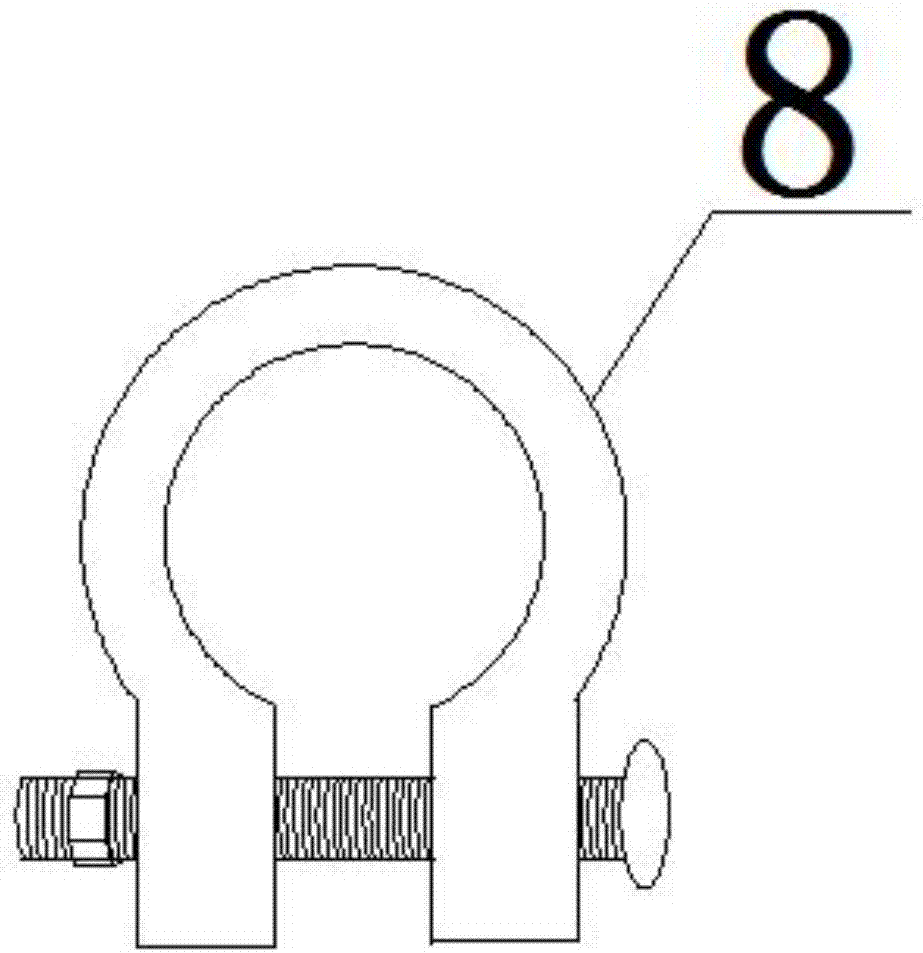

[0016] Example: such as figure 1 As shown, a simple cutting device for a small corrugating machine, including a corrugating machine 1, a cardboard 2, a frame 3, a motor 4, an electric rotating shaft 5, a circular cutting knife 6, an automatic horizontal cutting knife 7, a clamping buckle 8 and scale shaft 9; the frame 3 is provided at the paper outlet of the corrugating machine 1, the paper connecting plate 2 is provided on the frame 3, and baffles 10 are provided on both sides of the paper connecting plate 2, In order to prevent positional deviation after corrugated paper is output, which is not conducive to accurate cutting of corrugated paper, the electric rotating shaft 5 is arranged behind the cardboard 2 and between the legs on both sides of the frame 3. The electric rotating shaft 5 One end of 5 is connected with described motor 4, is provided with described circular cutting knife 6 on described electric rotating shaft 5, and the both sides of described circular cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com