Intercepting method for gas gushing out during tunnel construction

A tunnel construction and gas technology, applied in tunnels, gas discharge, earthwork drilling and mining, etc., can solve problems such as gas gushing out, affecting the construction period, and reducing the tunneling speed of the face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

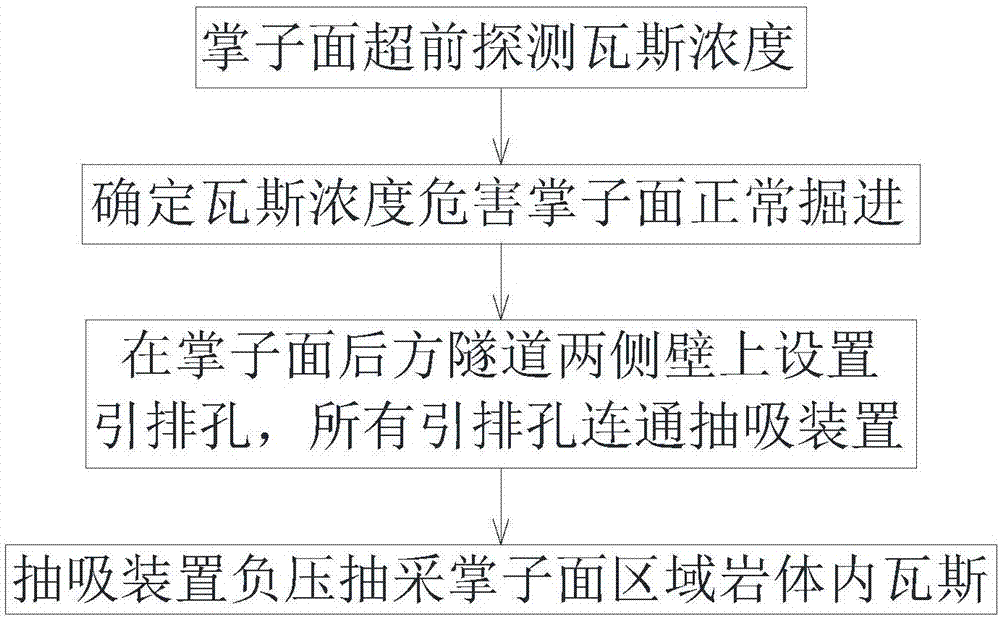

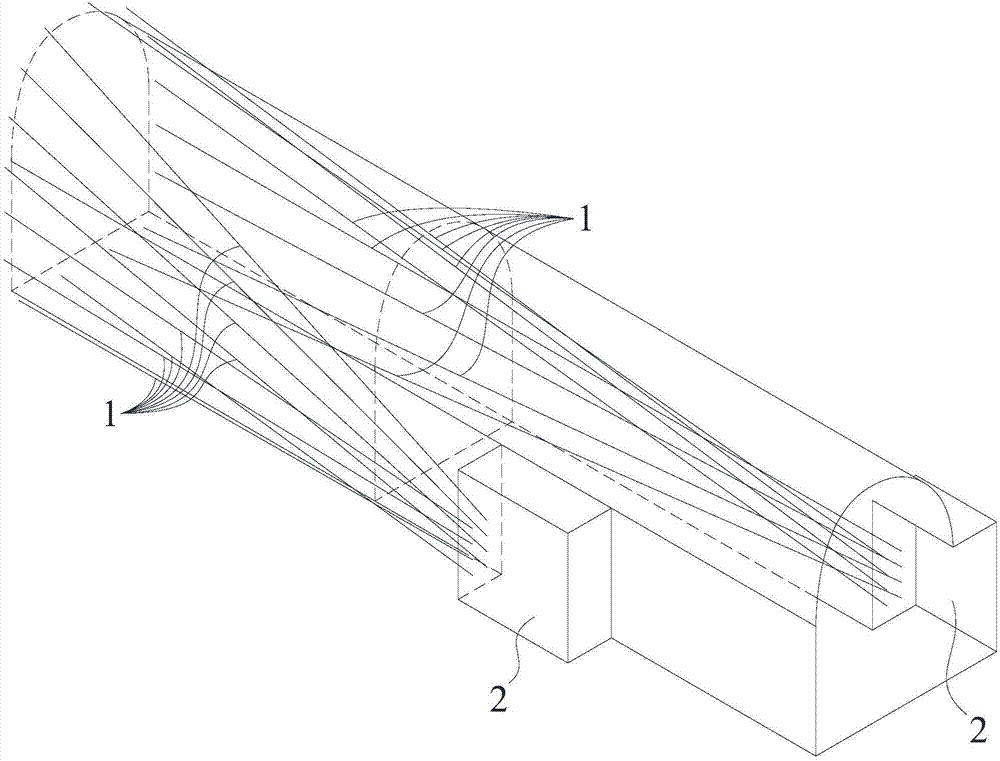

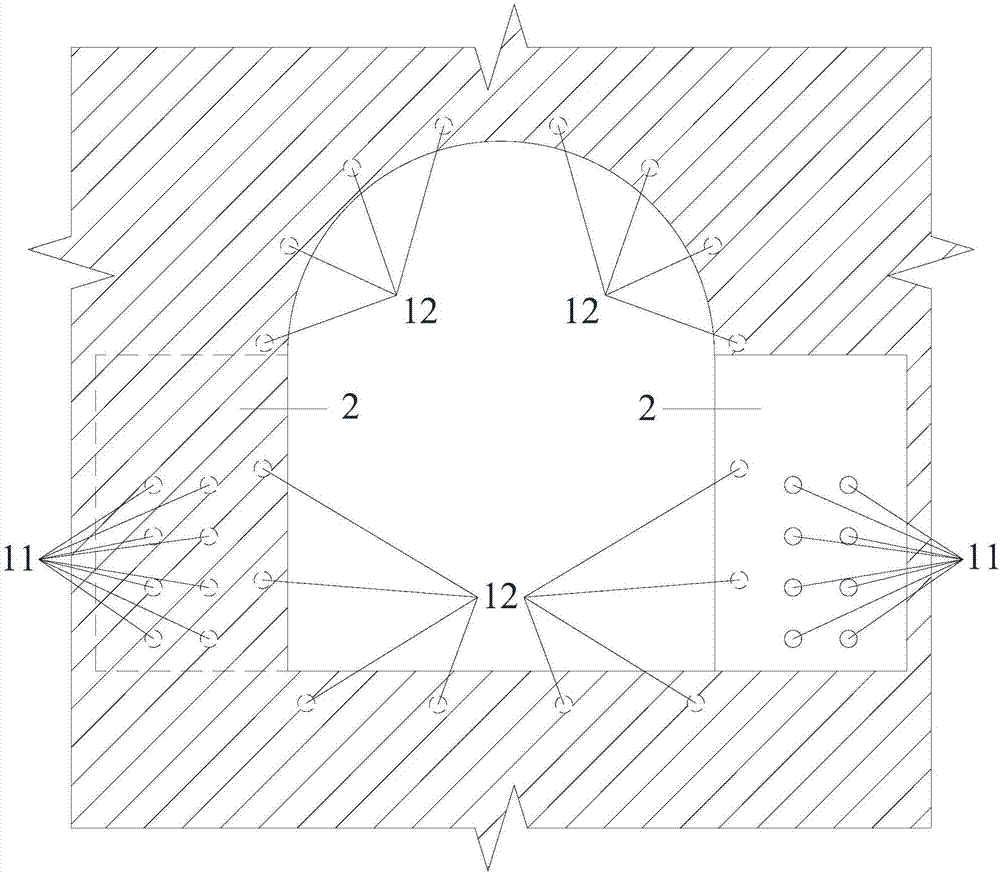

[0036] Such as Figure 1-3 Shown, a kind of tunnel construction gushing gas interception method described in the present invention comprises the following steps:

[0037] A. Advance detection of gas concentration on the face of tunnel excavation;

[0038] B. Guide the tunnel construction according to the real-time value of the gas concentration in step A, until the tunnel face advances in gas concentration and endangers the normal excavation work of the tunnel face;

[0039] C. Set 16 drainage holes 1 with a diameter of 108mm on both side walls of the tunnel 10m behind the tunnel face, and each drainage hole 1 extends along the tunnel excavation direction to the rock mass ahead of the tunnel face, and The end points 12 of all the drainage holes 1 are arranged along the periphery of the tunnel, and the starting points 11 of all the drainage holes 1 are connected to the suction device;

[0040] D. The suction device extracts the gas in the rock body in the face area under nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com