Heat power system suitable for deep peak adjusting of heat supply unit and peak adjusting method of heat power system

A technology for heating units and thermal systems, applied in steam applications, mechanical equipment, steam engine installations, etc., can solve problems such as imbalance, power generation exceeding power demand during heating period, and excess power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

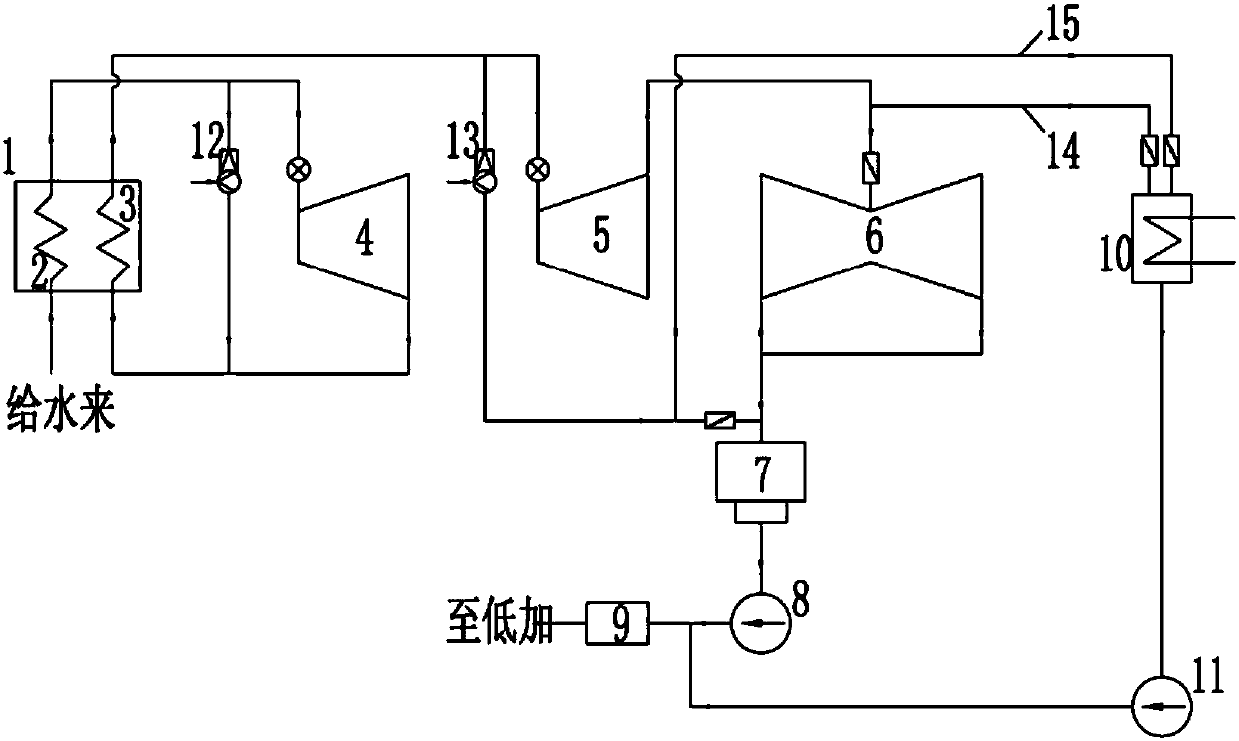

[0021] Such as figure 1 As shown, the thermal system of this embodiment is suitable for deep peak regulation of heating units, which includes heating elements, high pressure cylinder 4, high bypass valve 12, medium pressure cylinder 5, low pressure cylinder 6, low bypass valve 13, heating network heating device 10, heat network heater steam source pipeline 14, heat network drain pump 11, condenser 7, condensate pump 8 and condensate polishing device 9; the high side valve 12 is connected in parallel with the high pressure cylinder 4, and one end is connected with the The superheater of the heating element is connected, the other end is connected to the reheater of the heating element, the low bypass valve 13 is connected in parallel with the medium pressure cylinder 5 and the low pressure cylinder 6 and the three are arranged in the heating Between the reheater of the element and the condenser, the other end of the condenser is sequentially connected with a condensate pump 8 a...

Embodiment 2

[0025] On the basis of Embodiment 1, this embodiment further provides a thermal system peak regulation method suitable for deep peak regulation of heating units as described above: part of the main steam generated by the boiler superheater enters high pressure, The other part enters the high-bypass valve installed in parallel with the high-pressure cylinder, and the steam after entering the high-pressure cylinder is reduced in temperature and pressure, and then merges with the exhaust steam of the high-pressure cylinder, and enters the boiler reheater; Part of the reheated steam from the reheater enters the medium-pressure cylinder, and the other part enters the low bypass valve, and part of the exhaust steam from the medium-pressure cylinder is extracted for heating.

[0026] The intake air volume of the main steam generated by the boiler superheater entering the high-pressure cylinder is determined according to the load requirement of deep peak regulation.

[0027] The steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com