Zero return control method and system of worktable

A control method and workbench technology, applied in the direction of electric speed/acceleration control, etc., can solve the problems of single zero return mode, inability to cope with precise zero return requirements, and insufficient integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

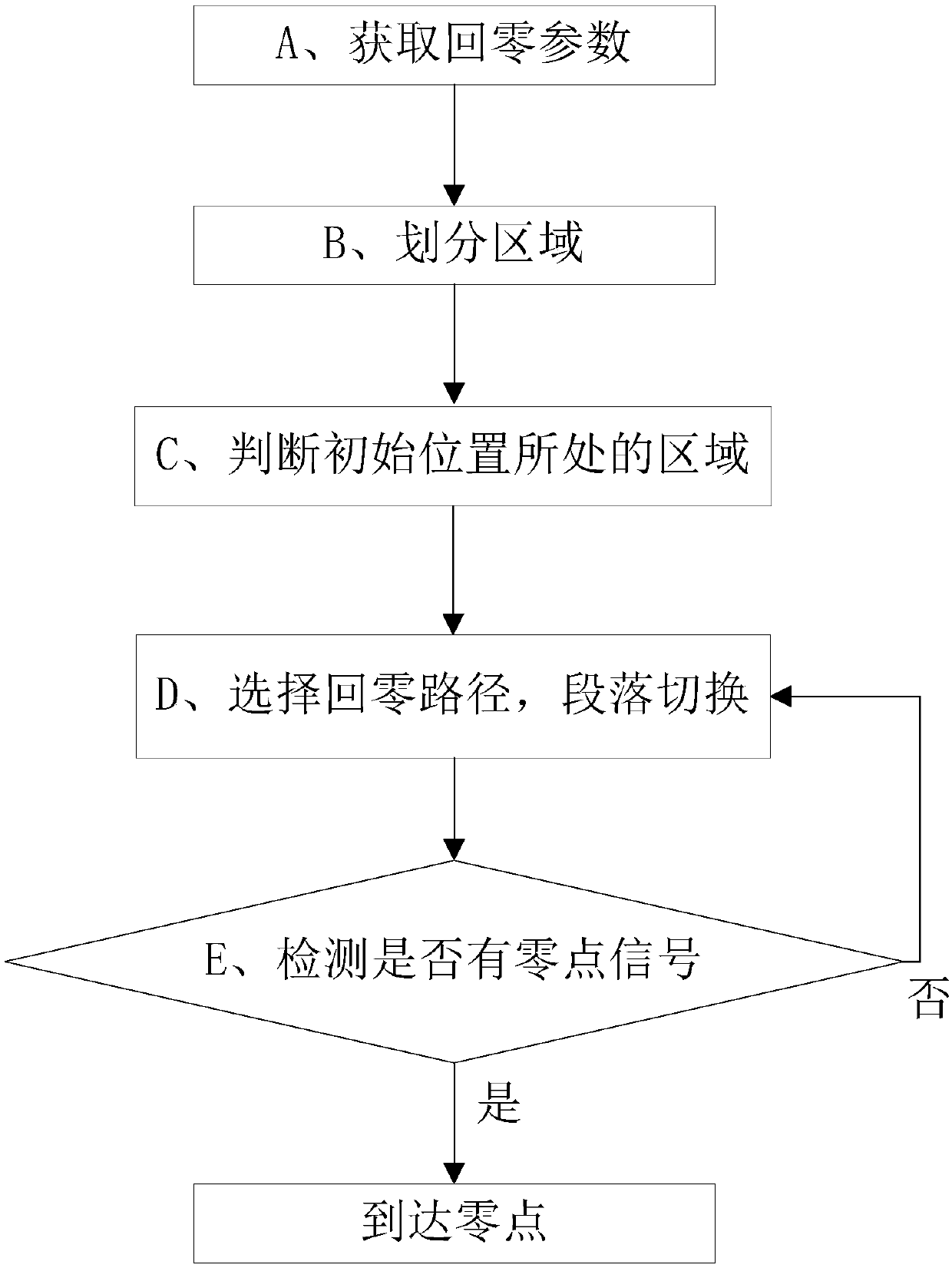

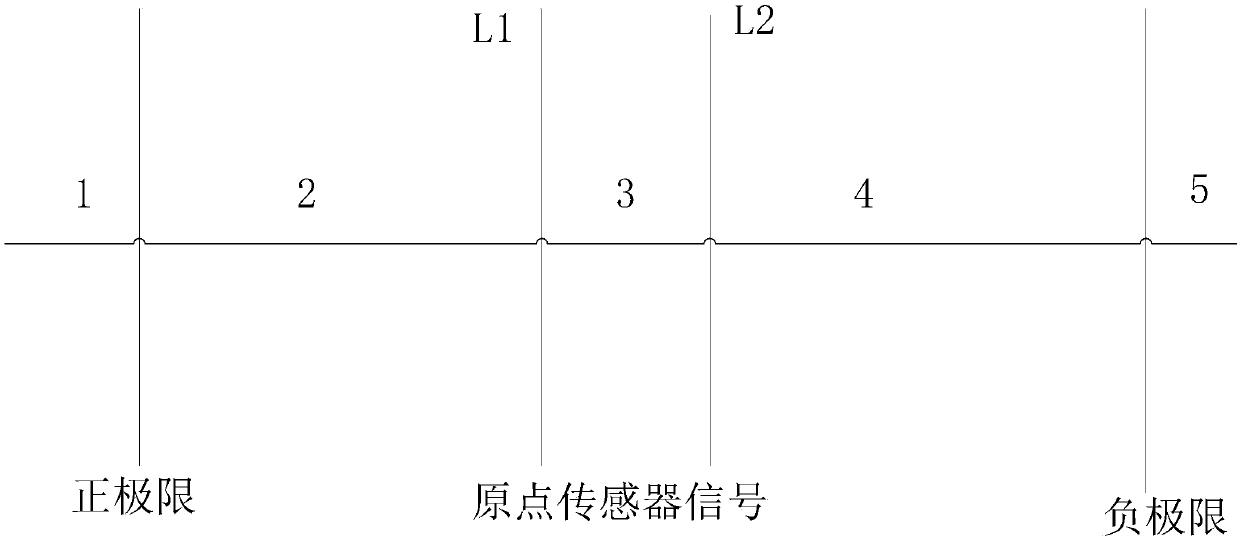

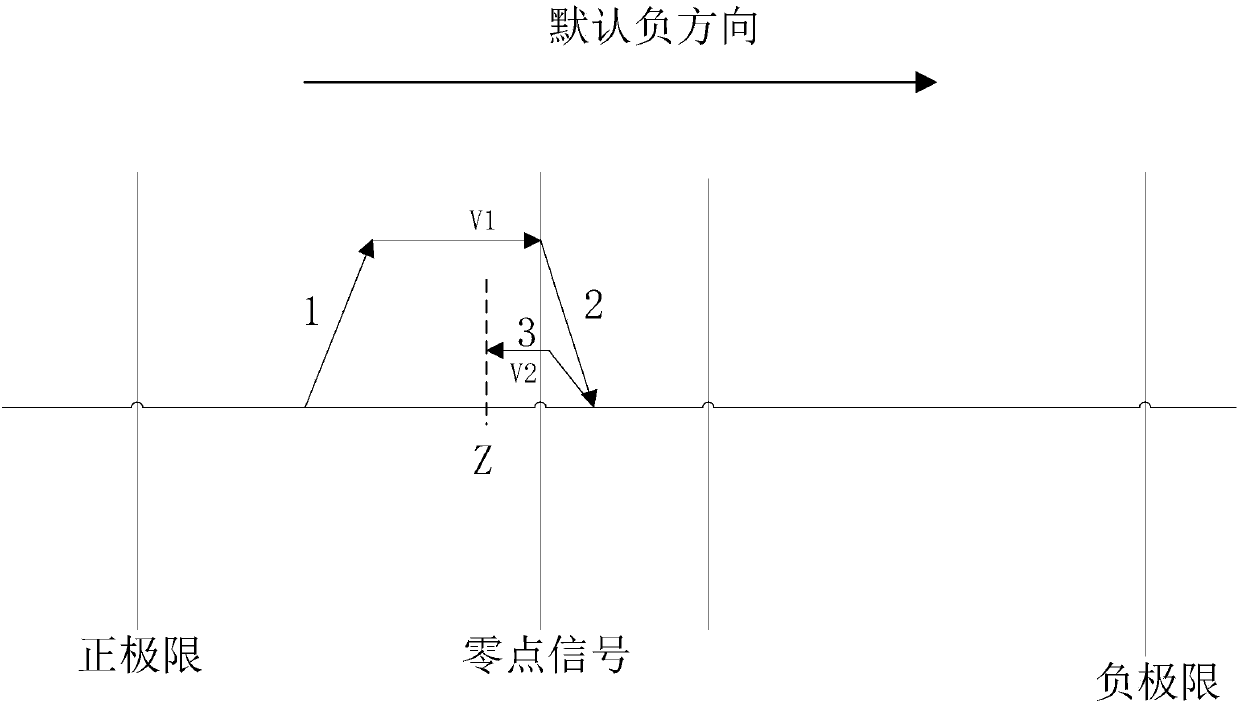

[0074] Based on the existing zero return control scheme, there is a technical problem that the user must manually control to ensure that the initial position of the workbench is in a specific area before the zero return can be realized, which is not only time-consuming and laborious, but also has strong limitations. Therefore, the present invention proposes a A technical solution for solving the above-mentioned technical problems, the basic concept of which is: according to the positive and negative limit signals and the origin sensor signal, the motion plane where the workbench is located (ie the stroke of the workbench) is divided into regions, and then the region corresponding to the position of the workbench is obtained , and then control the workbench to return from the area where it is located to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com