Step-by-step computer vision inspection device carrying movable darkroom

A technology of computer vision and detection devices, which is applied in the directions of measuring devices, analyzing materials, and optical testing for flaws/defects, etc. It can solve problems such as the inability to arrange production lines, the high cost of equipment and software purchases, and the inability of users to change independently, achieving low cost , to ensure the accuracy and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

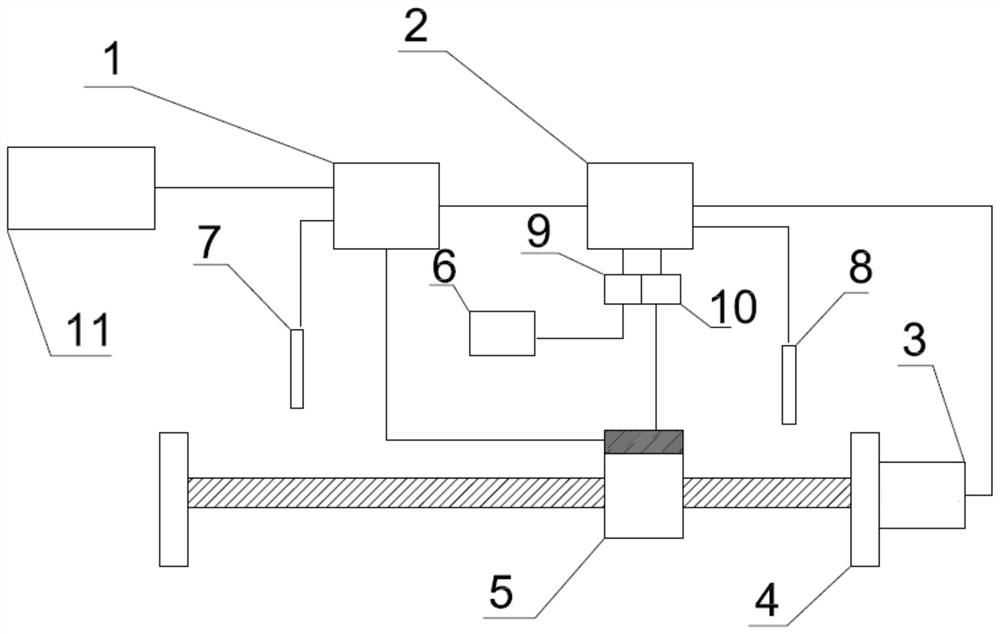

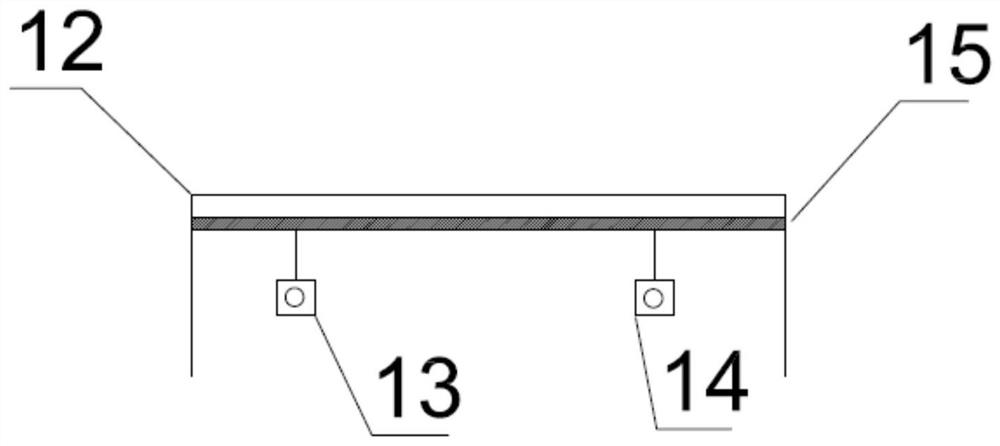

[0015] Such as figure 1 , figure 2 As shown, a step-by-step computer vision detection device equipped with a movable darkroom includes a visual detection computer 1, a single-chip microcomputer 2, a stepping motor 3, a lead screw 4, a display 11, a darkroom 12 and an auxiliary lighting lamp 15; 12. The camera and auxiliary lighting 15 are installed on the slide table 5 of the lead screw 4 through a cantilever structure, suspended above the parts to be tested, saving layout space, the stepping motor 3 provides power for the lead screw 4, and the stepping motor 3. Controlled by the single-chip microcomputer 2, the single-chip microcomputer 2 and the visual inspection computer 1 use a serial port for two-way communication, and the output of the visual inspection computer 1 is displayed on the display 11.

[0016] The two sides of the screw 4 are provided with two proximity switches, which are the parts in-position detection proximity switch 7 arranged far away from the stepper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com