Equipment for depositing fiber sliver into cans

A technology of fiber slivers and equipment, applied in the field of equipment for storing fiber slivers into cans, can solve problems such as difficult to achieve and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

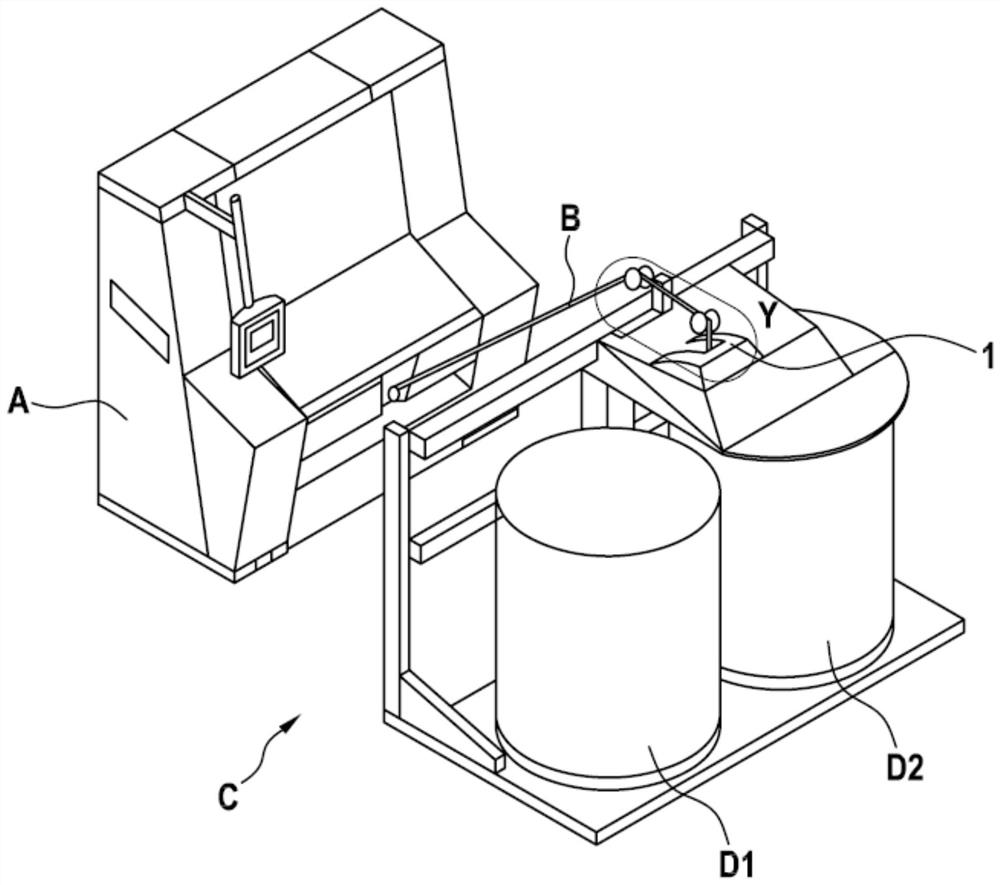

[0021] figure 1 A card A is shown, from which the fiber slivers B are guided via the coiling head 1 into the can changer C and deposited in the cans D1 , D2 . In this exemplary embodiment, the can changer C is designed as a linear can changer, in which the coiling head 1 is arranged so that it can move linearly along the frame or the frame wall.

[0022] However, the can changer C can also be designed as a rotating can changer, wherein the cans D1 , D2 are changed by means of a rotating device below the stationary coil head 1 . In this exemplary embodiment, the coil head 1 is arranged below a housing which is not shown in detail and is described in detail in the following figures.

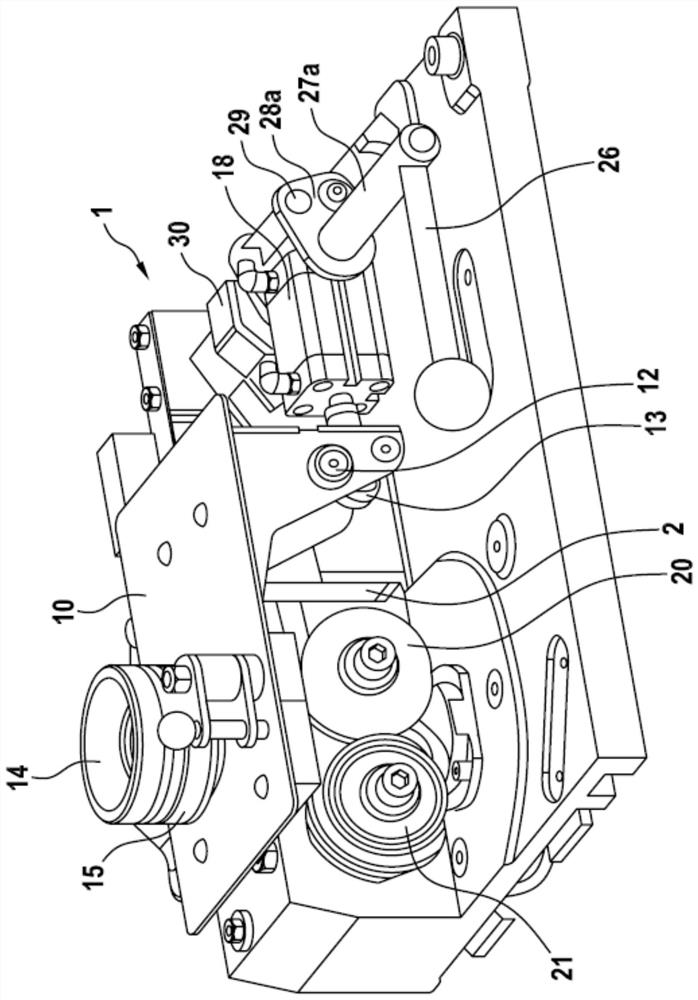

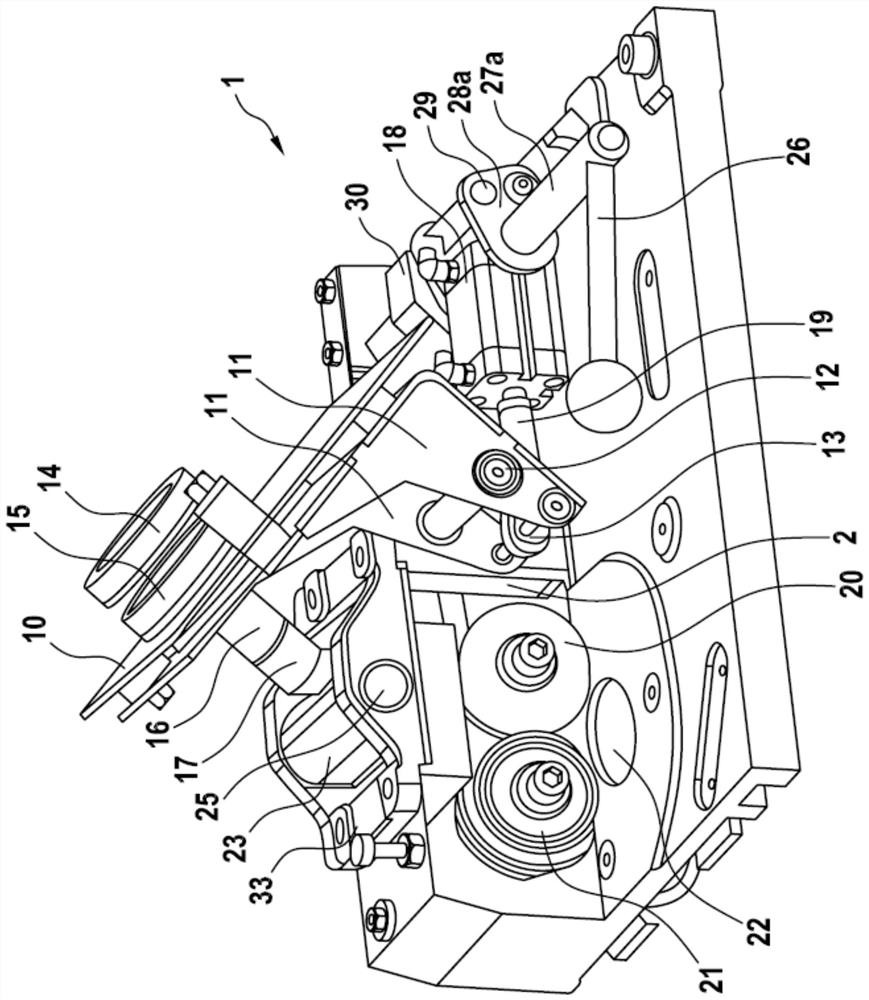

[0023] figure 2 The coil head 1 is shown in the ready-to-run position. Mainly the previous section funnel 16 and the fiber strip funnel 17 arranged below it (see image 3 ) and traction rollers 20,21. The fiber sliver is guided, for example, from the card to the coil head 1 of the can changer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com