High-altitude employment building material storage device

A technology for storage devices and building materials, applied in unloading devices, packaging, transportation and packaging, etc., can solve the problems of inappropriate high-altitude operations, inability to push out materials, and inconvenient access to materials, so as to achieve convenient placement or access to buildings. Plate, saving time and effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

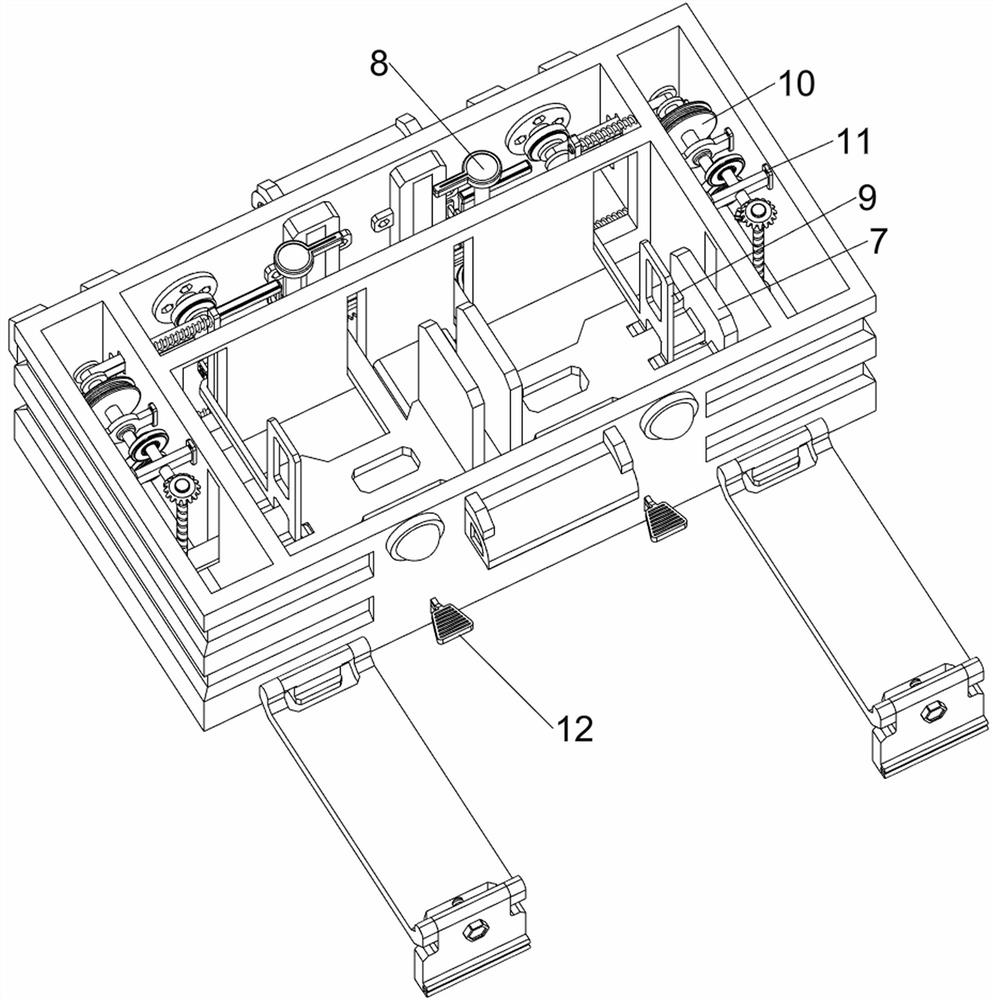

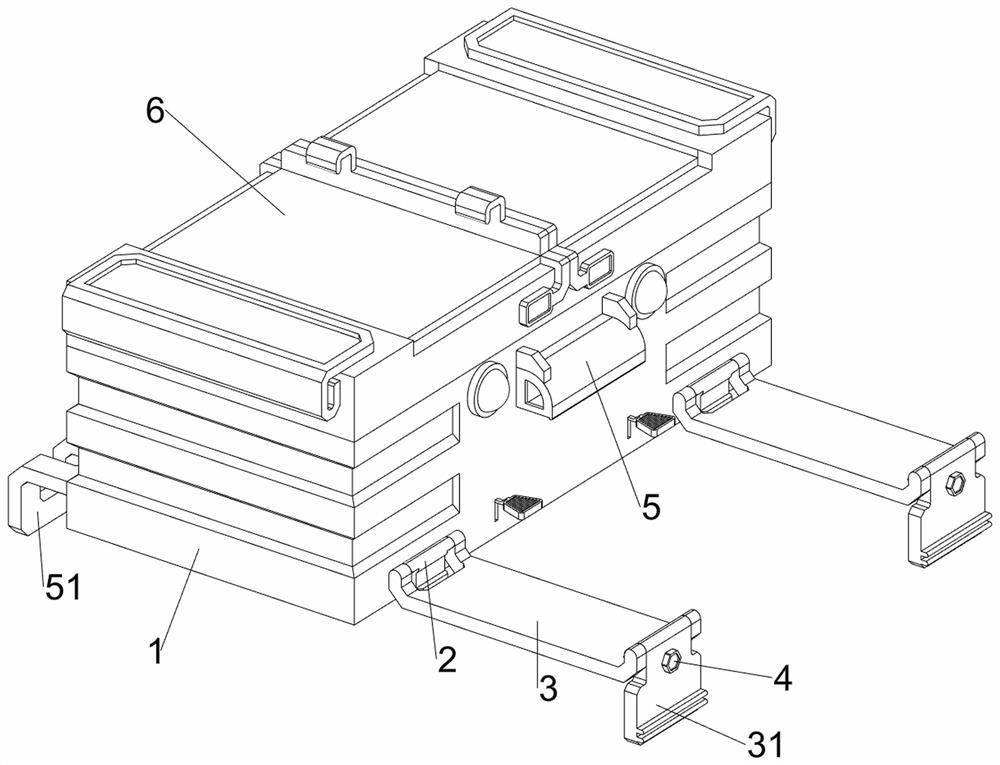

[0042] A storage device for high-altitude employment construction materials, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 17 As shown, it includes a storage box 1, a hinge block 2, a first hinge plate 3, a second hinge plate 31, a bolt 4, a handle 5, a fixed block 51, a slide cover 6, a lifting mechanism 7 and a material pushing mechanism 8, and stores Two hinged blocks 2 are installed on the front and rear sides of the lower part of the outer wall of the box 1, and the two hinged blocks 2 are left and right symmetrical. The side is hingedly connected with a second hinged plate 31, and the second hinged plate 31 is connected with a bolt 4 in a threaded manner. The bolt 4 cooperates with the first hinged plate 3, and the bolt 4 is used to fix the first hinged plate 3 and the second hinged plate. Plate 31, two hinged blocks 2 on the rear side are all hingedly connected with fixed block 51, and the front a...

Embodiment 2

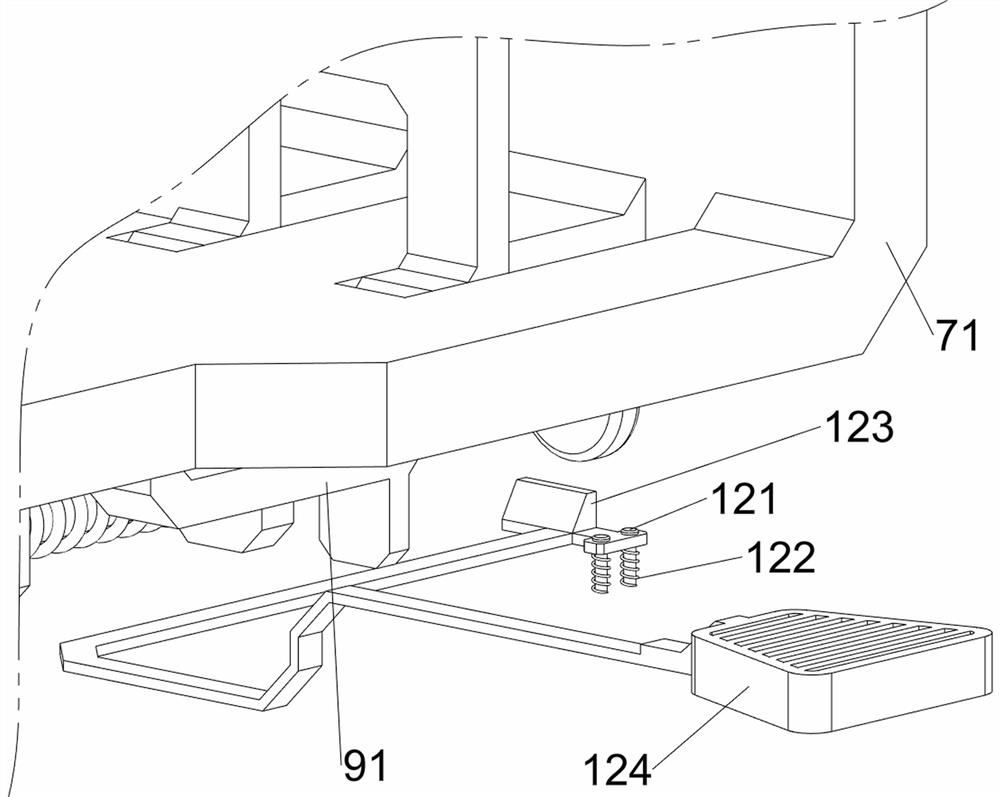

[0047] On the basis of Example 1, such as figure 2 , Figure 8 and Figure 9 As shown, a clamping mechanism 9 is also included, and the clamping mechanism 9 is used for clamping building panels. The clamping mechanism 9 includes a clamping block 91, a fixed rod 92 and a first spring 93, and the lower part of the discharge plate 71 is equipped with a fixed Rod 92, clamping block 91 is slidably connected on fixed rod 92, and clamping block 91 is slidably connected with discharge plate 71, and clamping block 91 is used for clamping building plate, between clamping block 91 and discharge plate 71 A first spring 93 is connected between them.

[0048] When placing building boards, the worker first manually pulls the clamping block 91 to move outward, and the first spring 93 is stretched. Under the action, the clamping block 91 moves to the inside and resets, and clamps the building board to prevent the building board from moving by itself. In this way, under the cooperation of ...

Embodiment 3

[0052] On the basis of Example 2, such as figure 2 , Figure 13 and Figure 14 As shown, a driving mechanism 11 is also included, and the driving mechanism 11 is used to drive the lifting mechanism 7 to automatically rise. The driving mechanism 11 includes a third rotating shaft 111, a second rubber wheel 112, a connecting plate 113, a fourth rotating shaft 114, a Three rubber wheels 115, the second one-way clutch 116, missing gear 117 and bevel gear 118, the third rotating shaft 111 is installed on the front side of the second rotating shaft 1010, the second rubber wheel 112 is installed on the front side of the third rotating shaft 111, storage box 1 The left and right sides of the inner wall are equipped with a connecting plate 113, the connecting plate 113 is located at the front side of the fixed plate 109, the middle part of the connecting plate 113 is rotatably connected with a fourth rotating shaft 114, and the rear side of the fourth rotating shaft 114 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com