Bath mirror airing placing device with timing function

A technology of timing device and function, which is applied in the direction of surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of occupying a large space, low cooling efficiency, affecting product quality, etc., and prevent mutual collision and friction , good air circulation, save the effect of drying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The present invention provides a bath mirror drying device with a timing function. In order to make the objectives, technical solutions and effects of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

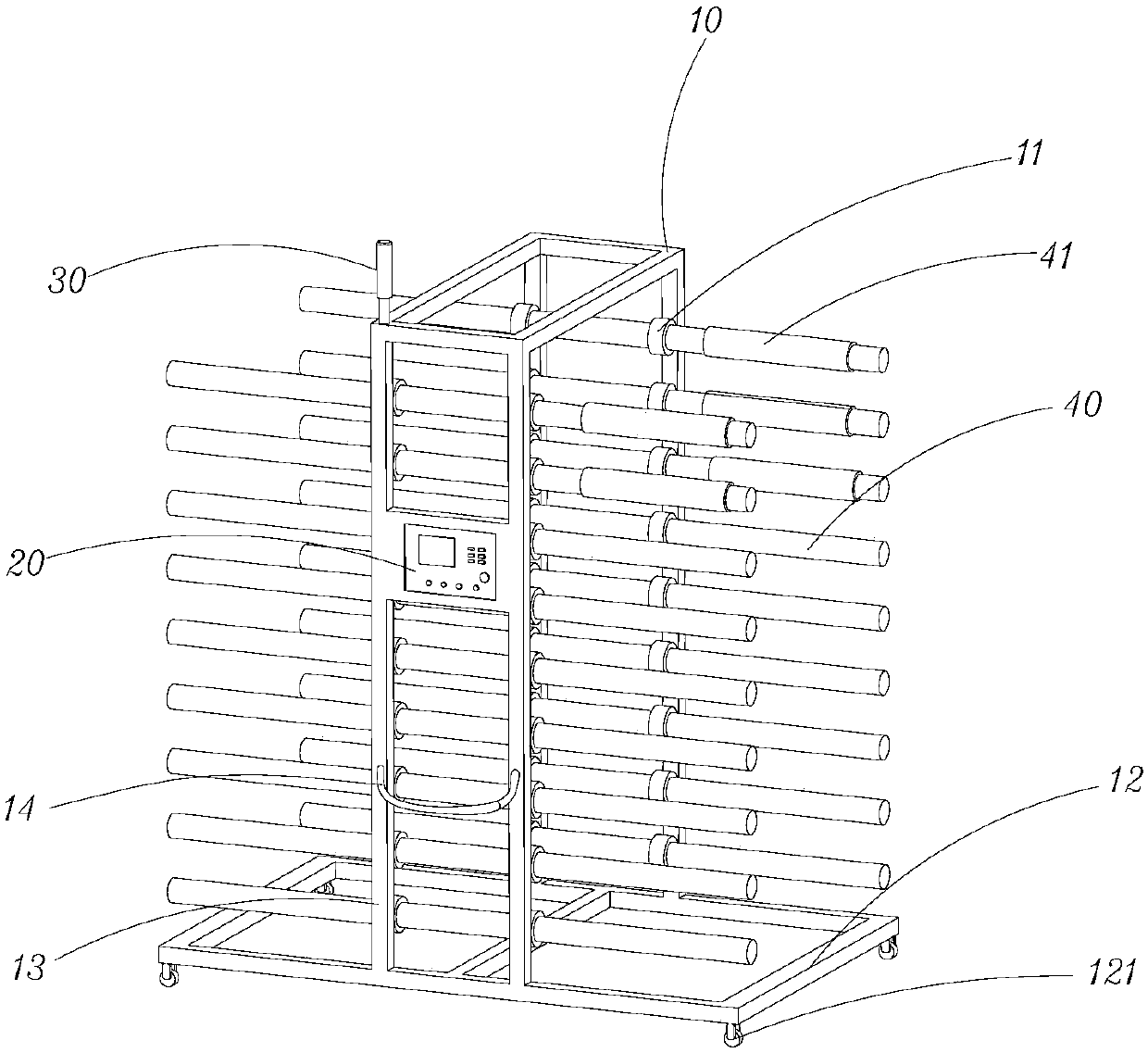

[0016] The invention provides a bath mirror drying device with a timing function, and its structure is as follows figure 1 Shown, including:

[0017] The bracket 10 and the timing device 20, the alarm device 30 and the support bar 40 arranged on the bracket 10 are provided with a plurality of support bar insertion holes 11 at different height positions, and the support bars 40 are inserted into the 孔11中.

[0018] Further, the outer periphery of the support bar 40 is covered with a plastic soft rubber tube 41, and the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com