Connection element, ceiling joist assembly and assembly method

A pendant and component technology, which is applied in ceilings, building components, buildings, etc., can solve the problems of low decoration efficiency and ceiling installation methods that cannot meet the requirements of industrialization of architectural decoration, etc., and achieve fast and efficient construction, good construction environment, and fast installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

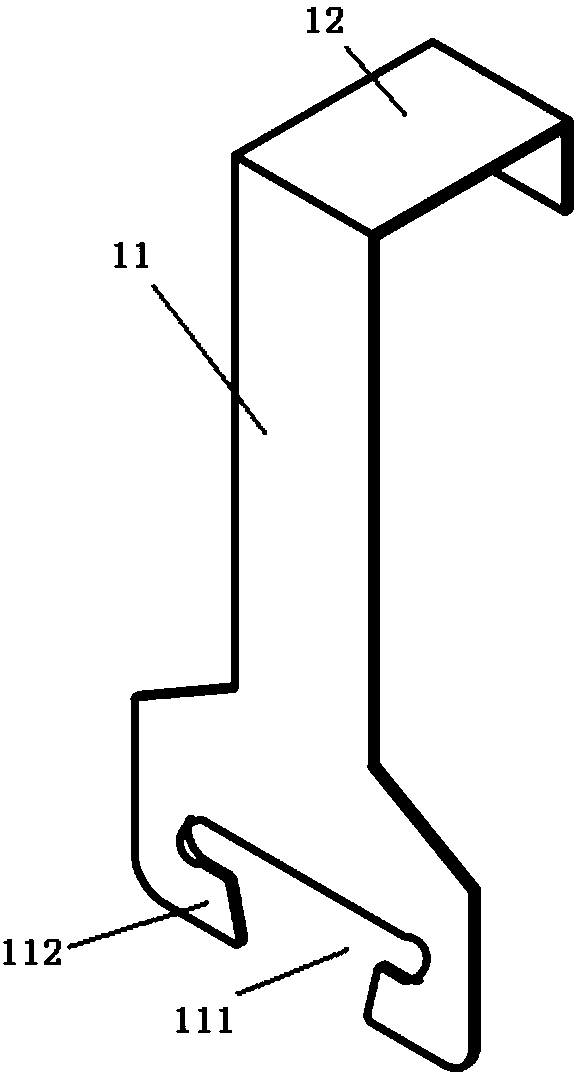

[0042] This embodiment provides a pendant, such as figure 1 As shown, it includes a hanging plate 11 and a bending portion 12, wherein the first end of the hanging plate 11 is formed with an engaging groove 111, and the engaging groove 111 is suitable for embedding a triangular keel bottom plate, and the engaging groove 111 Both sides of the notch extend toward the center of the notch with hooking parts 112, and the hooking parts 112 are parallel to the bottom of the hooking groove 111; the bending part 12 includes a top plate and a side plate, so The first end of the top board is connected to the first end of the side board, the second end of the top board is connected to the second end of the hanging board 11, the hanging board 11 is perpendicular to the top board and the The hanging board 11 and the side board are located on the same side of the top board; the distance between the hanging board 11 and the side board is adapted to the width of the main keel on the top frame ...

Embodiment 2

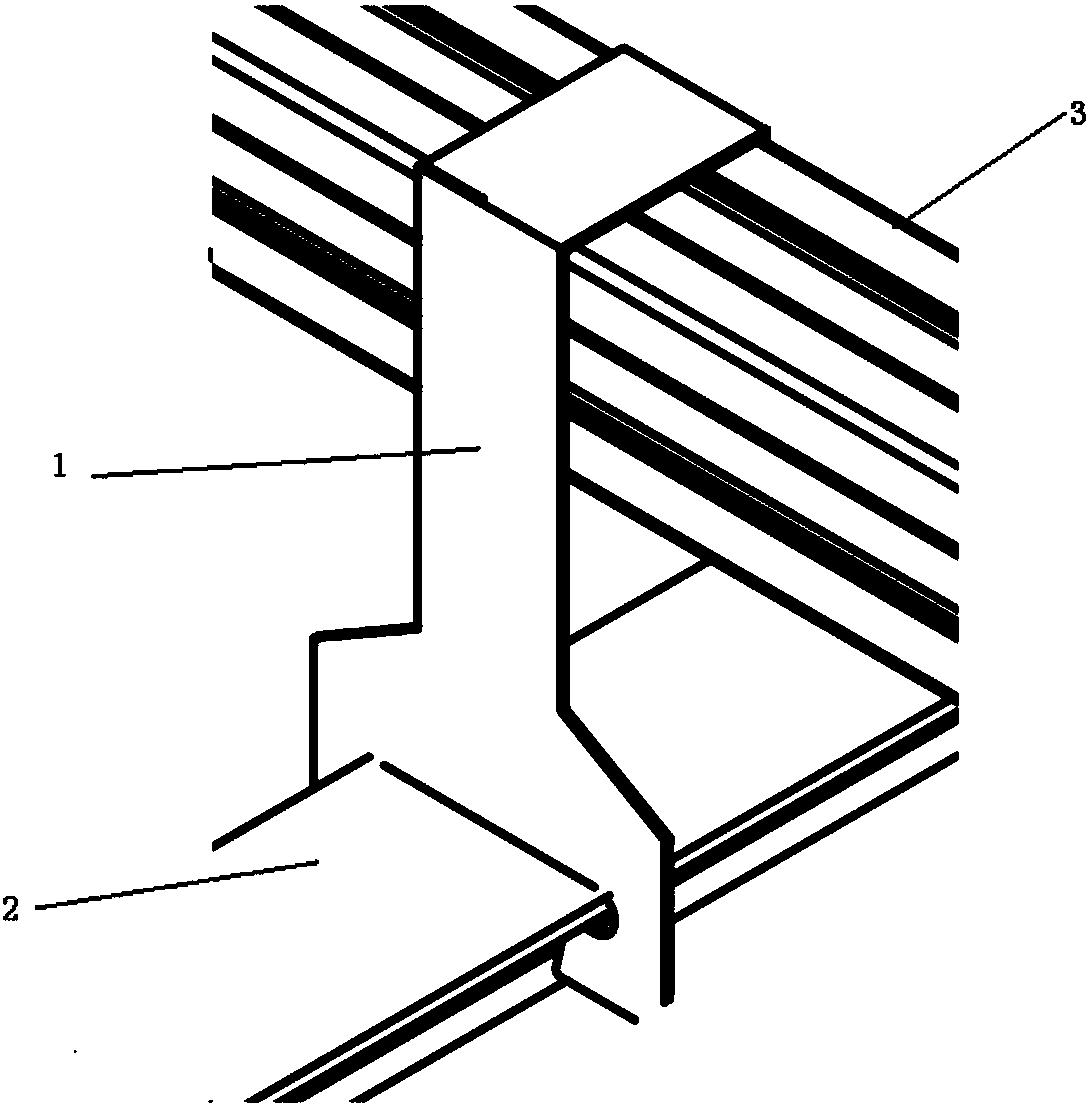

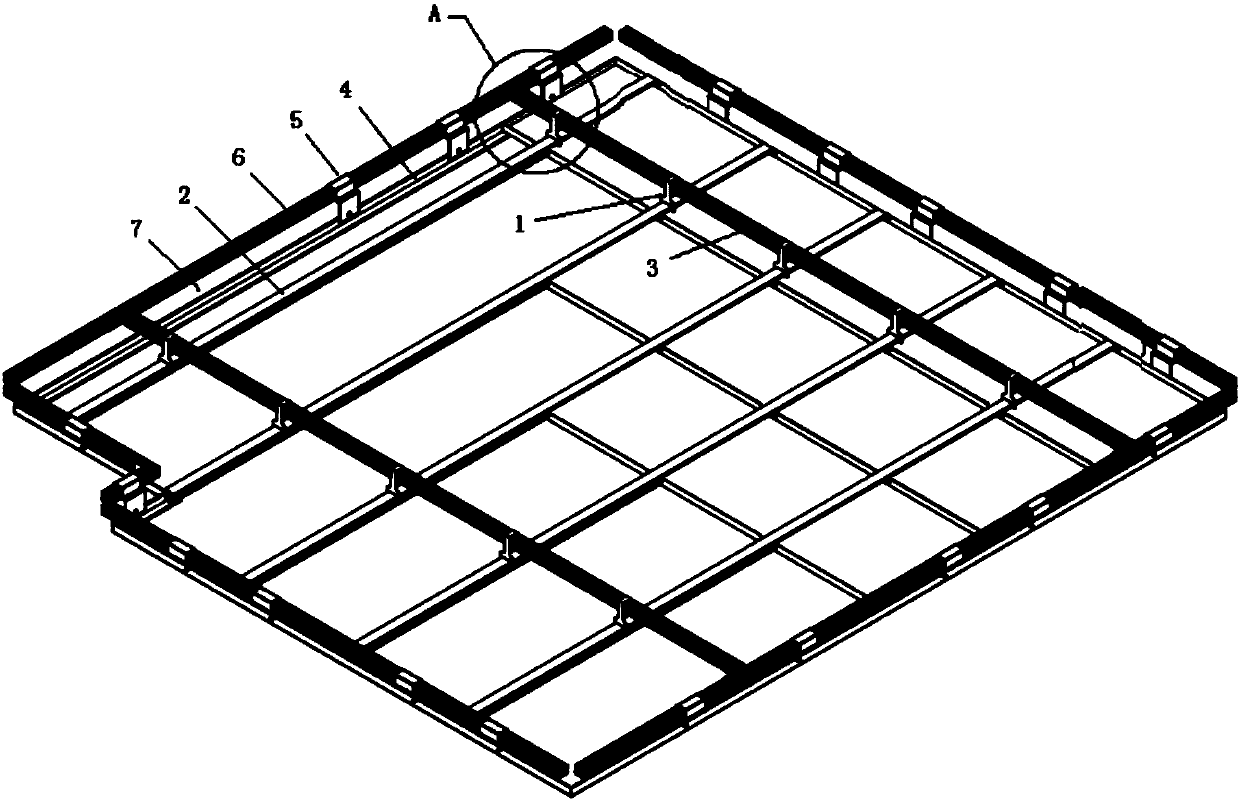

[0047] This embodiment provides a ceiling keel assembly, such as image 3 and Figure 4 As shown, it includes main keel 3, side keel 4, triangular keel 2 and pendant 1. The two ends of the main keel 3 are respectively fixed on the inner side of the top frame 6 of the toilet frame, and its cross section is square; The lower setting; the bottom plate of the triangular keel 2 is embedded in the hooking groove of the pendant 1, and the two edges of the bottom plate are clamped by the hooking parts on both sides of the notch of the hooking groove; The keel 4 is an L-shaped plate, and the first side of the L-shaped plate is suitable for being fixed on the wall panel 7 of the toilet frame, wherein the wall panel 7 is installed on the top frame 6 and the bottom frame (not shown) of the toilet frame )between.

[0048] As can be seen from the figure, there are a plurality of main keels 3 and a plurality of triangular keels 2 on the inside of the bathroom frame top frame 6, and the nu...

Embodiment 3

[0055] This embodiment provides a method for assembling a ceiling joist assembly. The ceiling joist assembly is assembled after the toilet frame is assembled, wherein the toilet frame includes a top frame, a bottom frame, and a frame installed between the top frame and the bottom frame. Between the wall panels, the assembly method of the ceiling keel assembly includes the following steps:

[0056] Step 1: Install the side keel on the wallboard; this step specifically includes: connecting the square slot of the ceiling clip to the outside of the top frame of the toilet frame; inserting the first side of the side keel into the bottom to top between the wallboard and the ceiling clamp mounting plate; after the positioning piece passes through the positioning through hole on the ceiling clamp mounting plate and the fixing hole on the first plate, the side keel is fixed on the the wallboard.

[0057] Step 2: Install the main keel on the inside of the top frame of the bathroom fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com