A test bench for oil seal sealing performance intelligently simulating paddy field environment

An intelligent simulation and oil seal technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of reduced sealing performance, difficult sealing performance, and reduced service life of the machine, achieving real sealing performance, low manufacturing cost, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

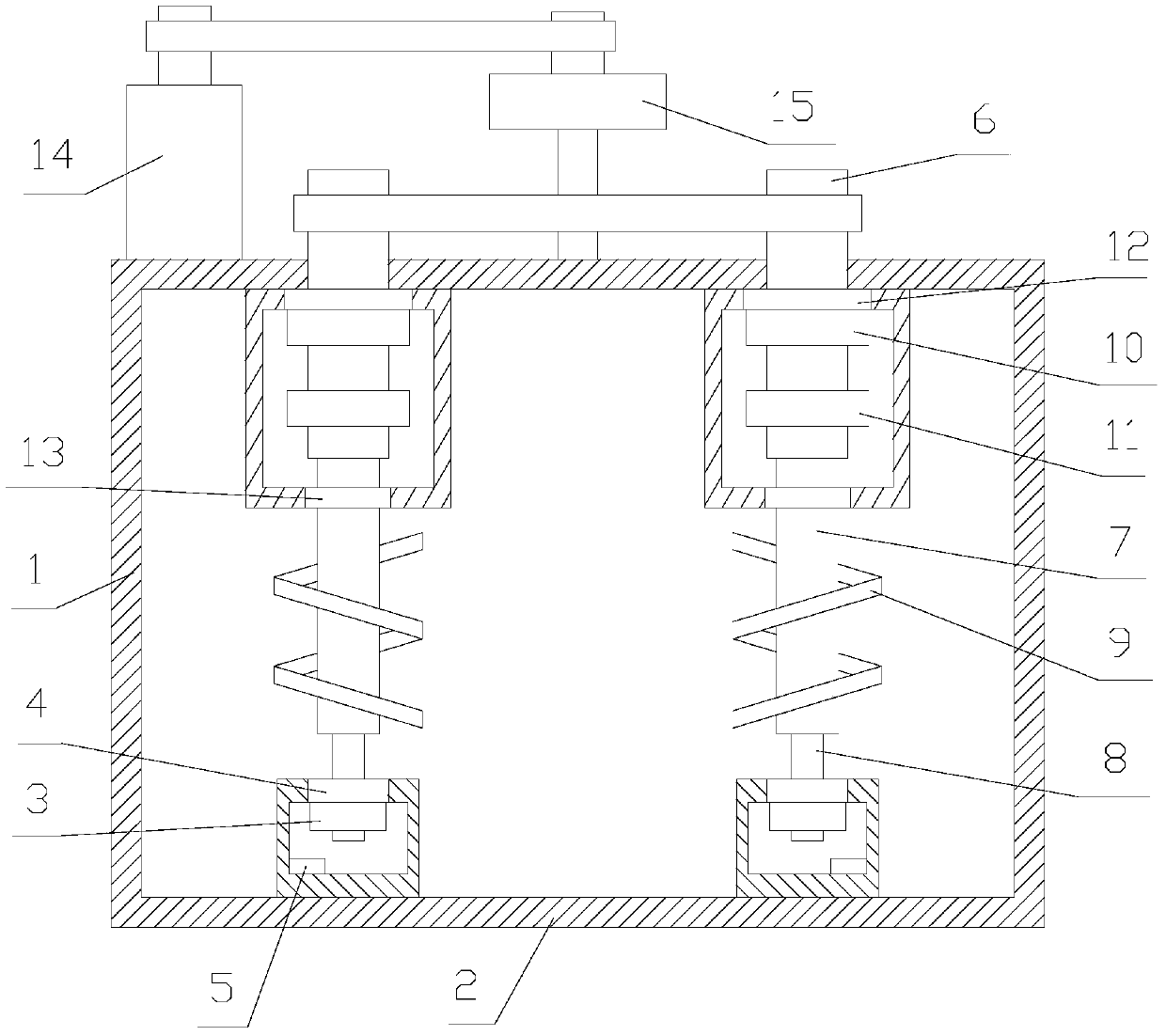

[0023] refer to figure 1 :

[0024] The present invention proposes an oil seal performance test bench for intelligently simulating the paddy field environment, comprising a box body 1, a testing section, and a driving mechanism; the testing section includes a first cavity 2, a first bearing 3, a first oil seal 4, and a transmission shaft Components, stirring mechanism, leakage alarm device 5.

[0025] The first cavity 2 is located in the box body 1 , and a first mounting hole is provided on the first cavity 2 ; the first bearing 3 is located in the first cavity 2 .

[0026] The transmission shaft assembly includes a first rotating shaft 6, a second rotating shaft 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com