Fine-tuning peg for violin and plucked string instruments

A technology for plucked musical instruments and violins, which is applied to musical instruments, stringed instruments, violins, etc. It can solve the problems of unsupported or coordinated shaft sections, affecting the accuracy of fine-tuning, troublesome operation, etc., and achieves reasonable structure, fast and accurate adjustment, and good versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is further described below in conjunction with embodiment and accompanying drawing.

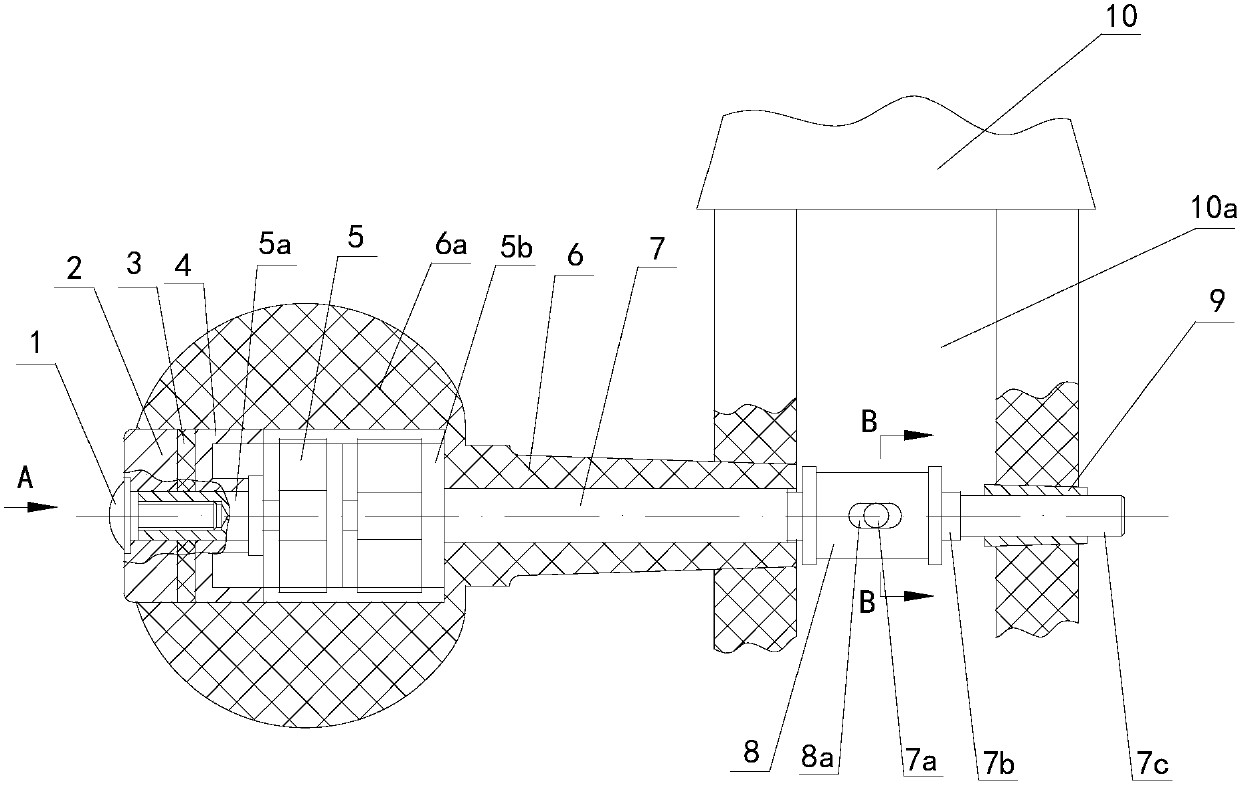

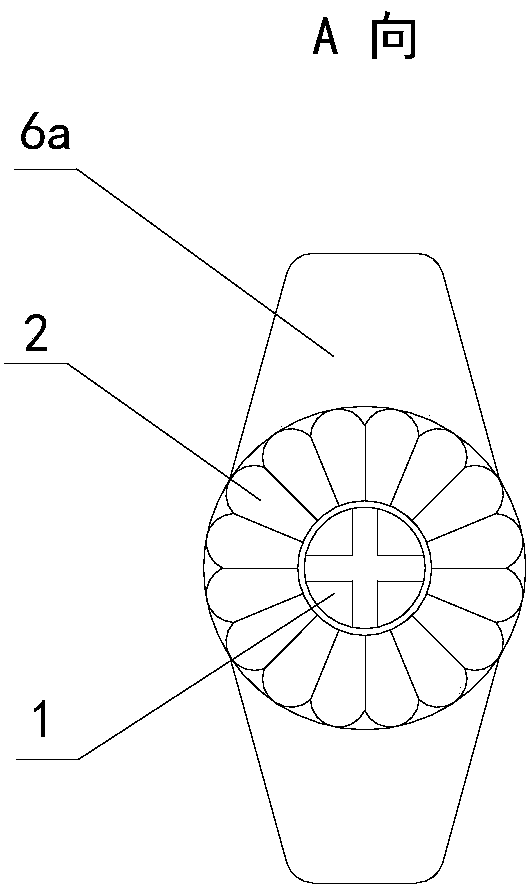

[0011] see figure 1 , figure 2 , image 3

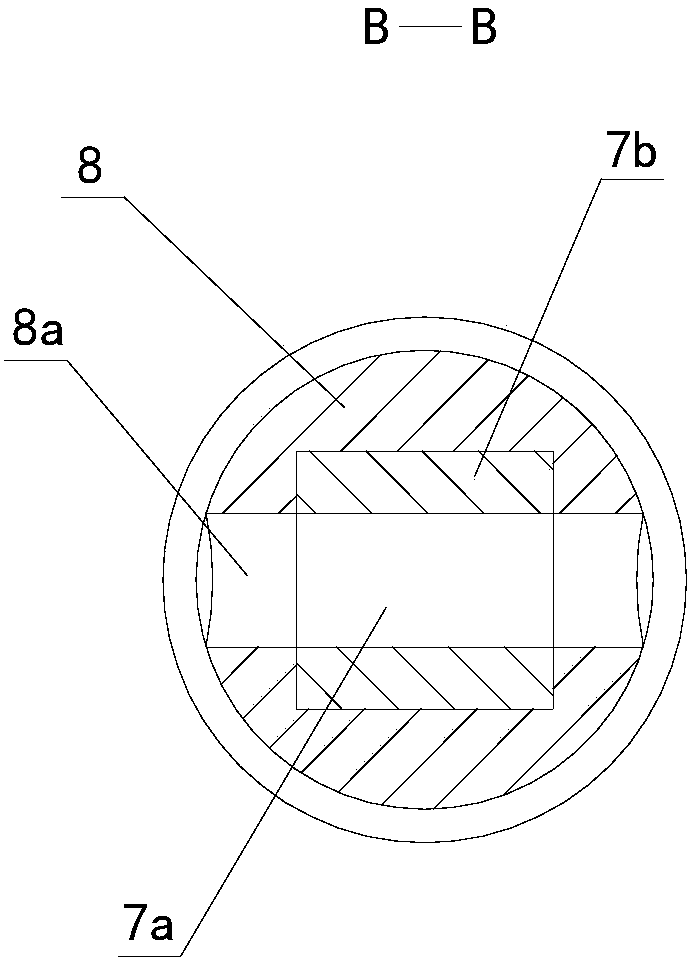

[0012] The fine-tuning peg used for violin and plucked stringed instrument provided by the present invention has a hollow axle body 6, and planetary speed reducer 5 is housed in the die cavity of shaft handle 6a of shaft body 6 rear ends, and the input shaft of planetary speed reducer 5 5a is connected with the knob 2 at the rear end of the shaft body through a screw 1, the shaft body 6 is equipped with a peg 7, the output shaft 5b of the planetary reducer 5 is connected with one end of the peg 7, and the other end of the peg 7 protrudes The shaft body, in this embodiment, the peg 7 is integrated with the output shaft 5b of the planetary reducer 5 . The part that protrudes outside the shaft body 6 around the peg 7 is divided into two sections, wherein the shaft section near the shaft body is a square shaft 7b in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com