Automobile gauge fixing device

A fixing device and checking tool technology, applied in the direction of using mechanical devices, measuring devices, mechanical measuring devices, etc., can solve the problems of not being able to prompt the staff, inconvenient to fix auto parts, and unable to meet the needs of users, and achieve a simple structure. , Easy to fix, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

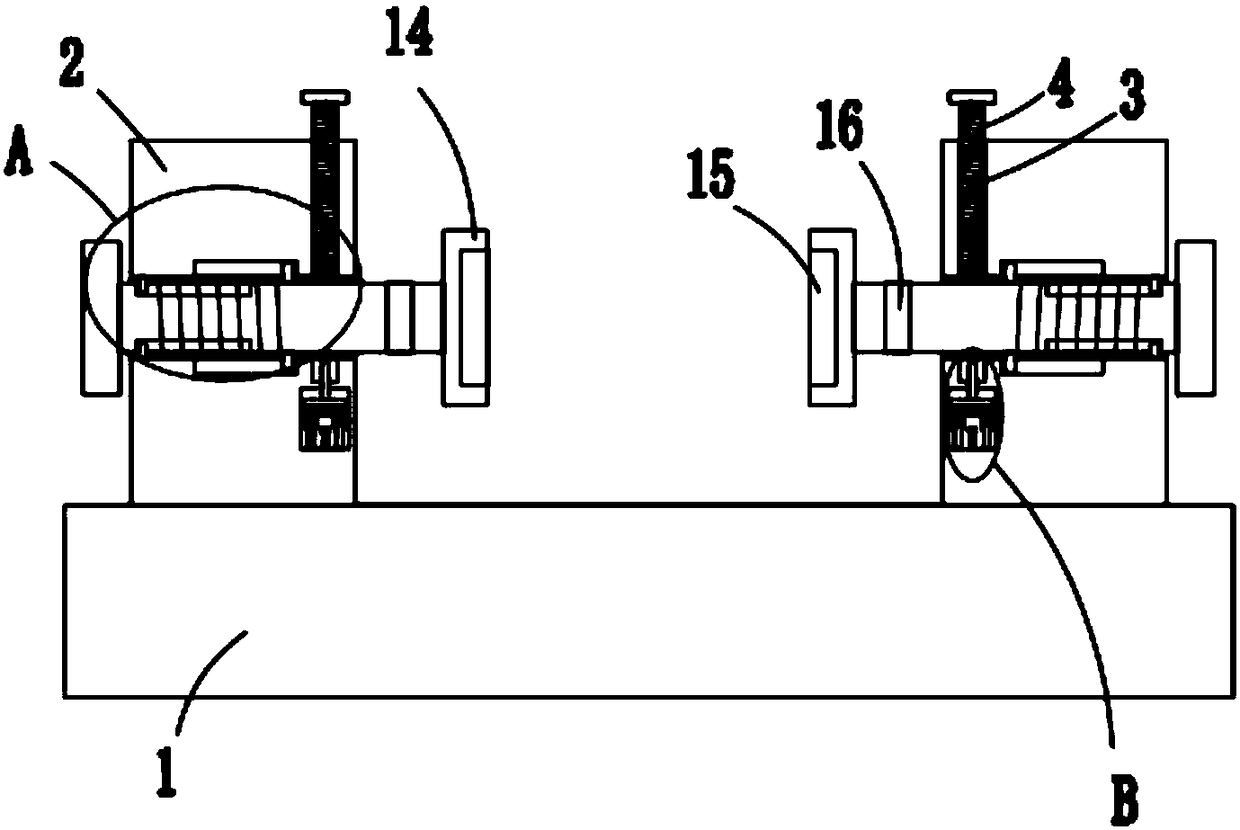

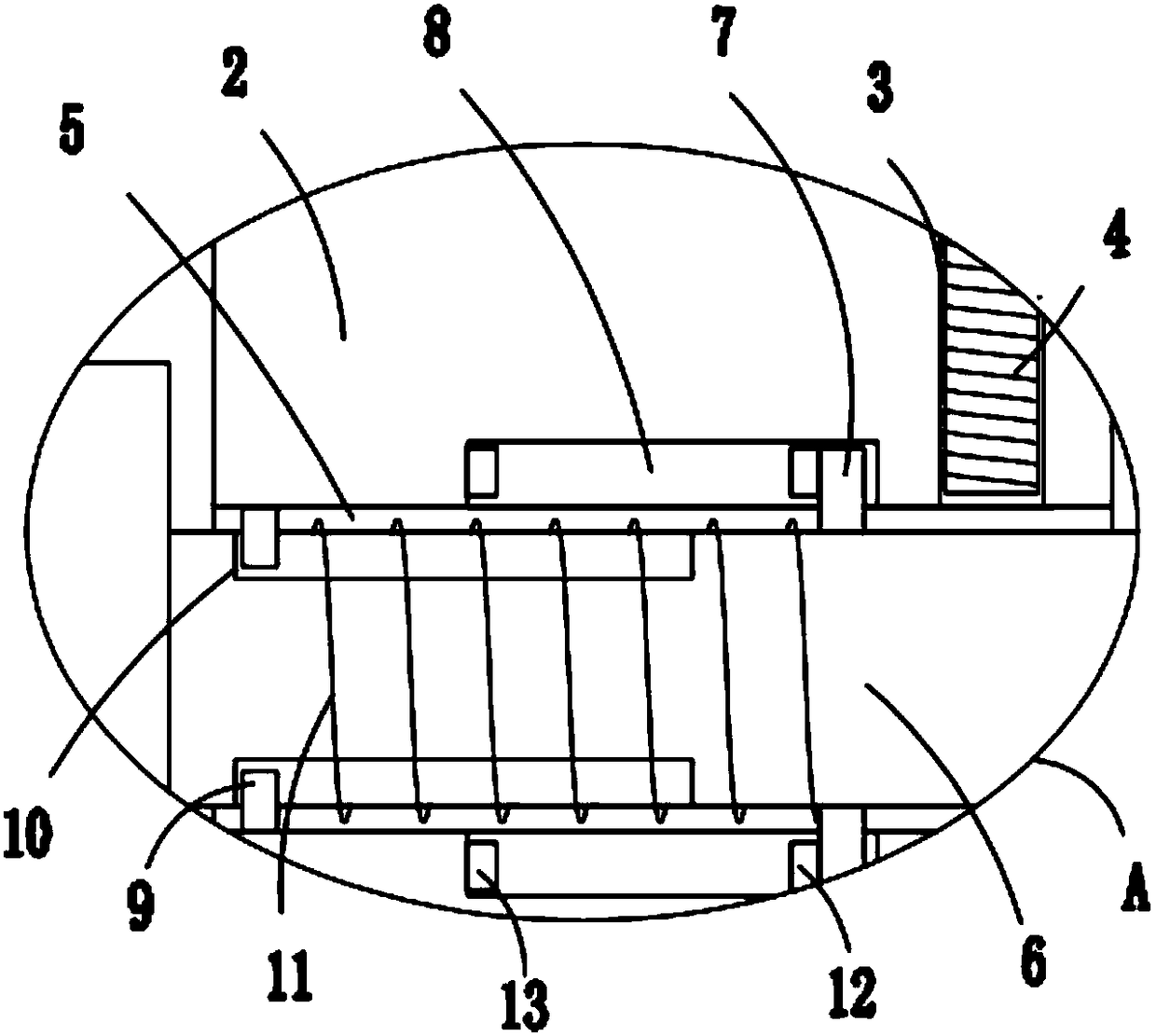

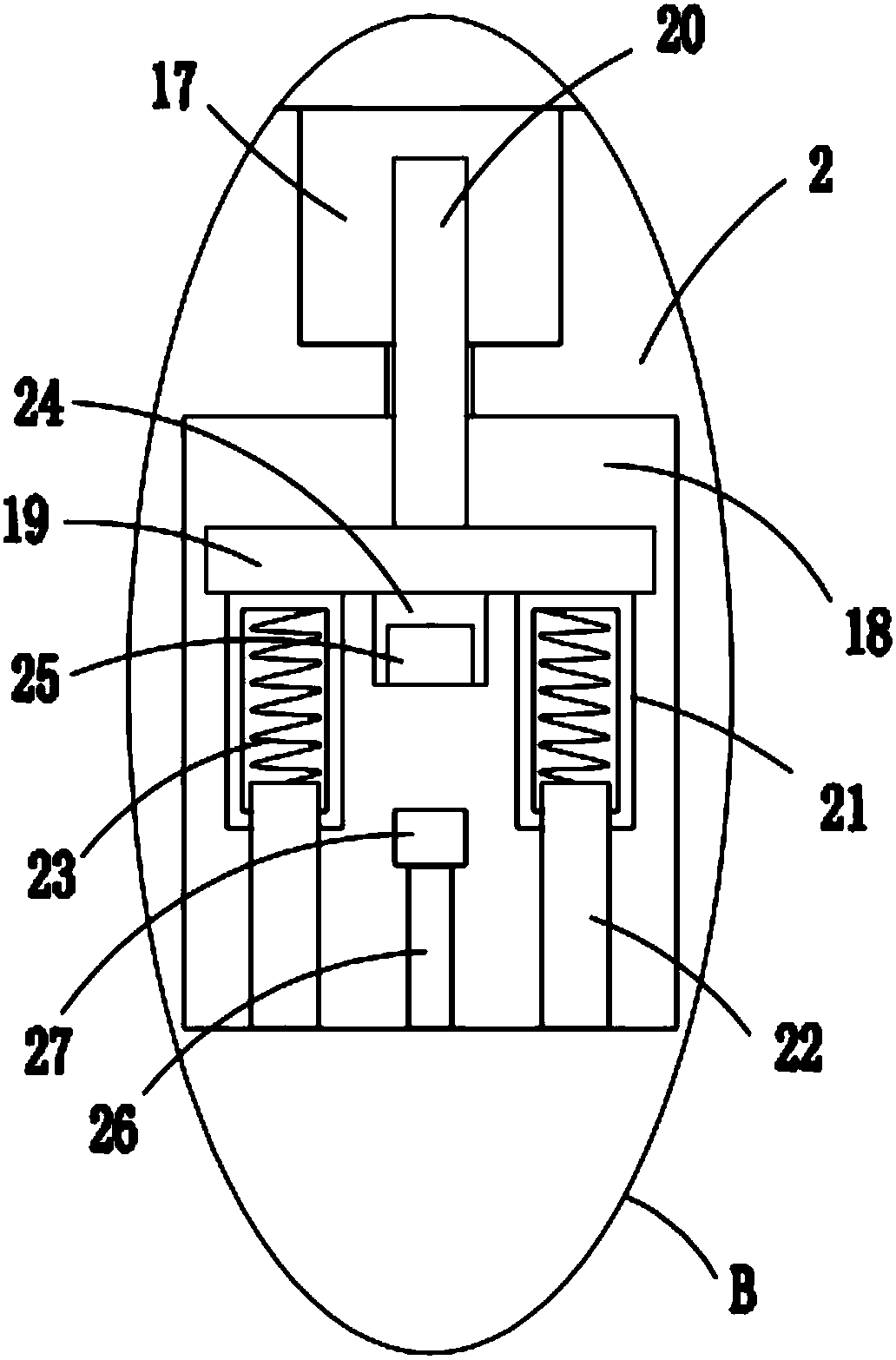

[0024] refer to Figure 1-5 , this embodiment proposes a fixing device for automobile inspection tools, including a mounting base 1, two mounting rods 2 are symmetrically welded on the top side of the mounting base 1, and the bottom ends of the two mounting rods 2 are provided with first threaded holes 3. The internal thread of the first threaded hole 3 is installed with a threaded column 4, the top of the threaded column 3 extends outside the first threaded hole 3, and a sliding hole 5 is opened on the mounting rod 2, and the sliding hole 5 communicates with the first threaded hole 3 , and the sliding rod 6 is slidably installed in the sliding hole 5, and both sides of the sliding rod 6 are welded with a limit block 7, and the limit block 7 is located on one side of the first threaded hole 3, and the inner walls of both sides of the sliding hole 5 are provided with The limiting groove 8, the limiting block 7 is slidably installed in the limiting groove 8, the inner walls of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com