Rotating structure of bevel gauge and lower prop of hot air seam sealing machine

A technology of rotating structure and sealing machine, which is applied in sewing equipment, textiles and papermaking, etc., can solve the problems of poor work adaptability and inconvenient operation, and achieve the effects of precise adjustment, increased work efficiency and improved work adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

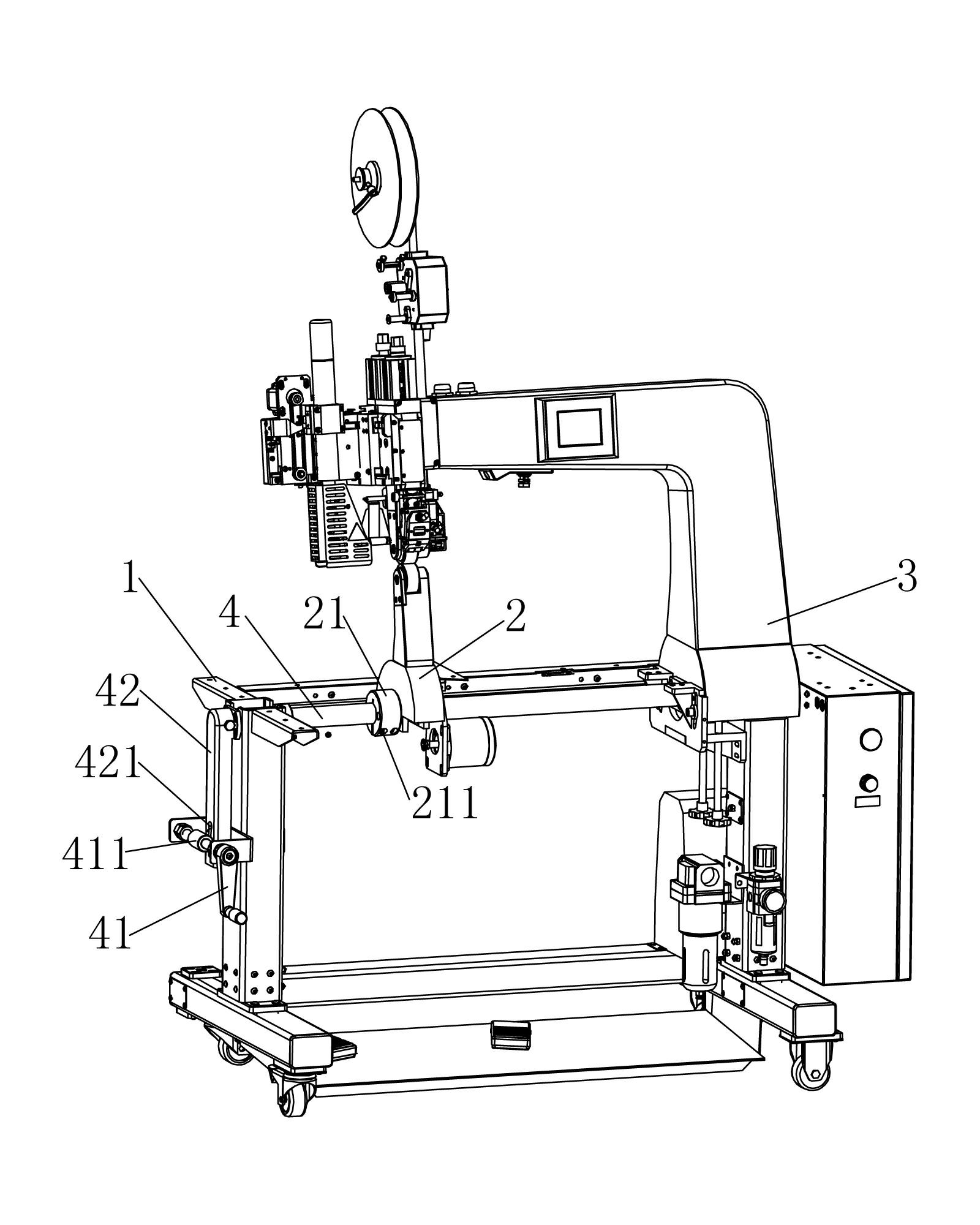

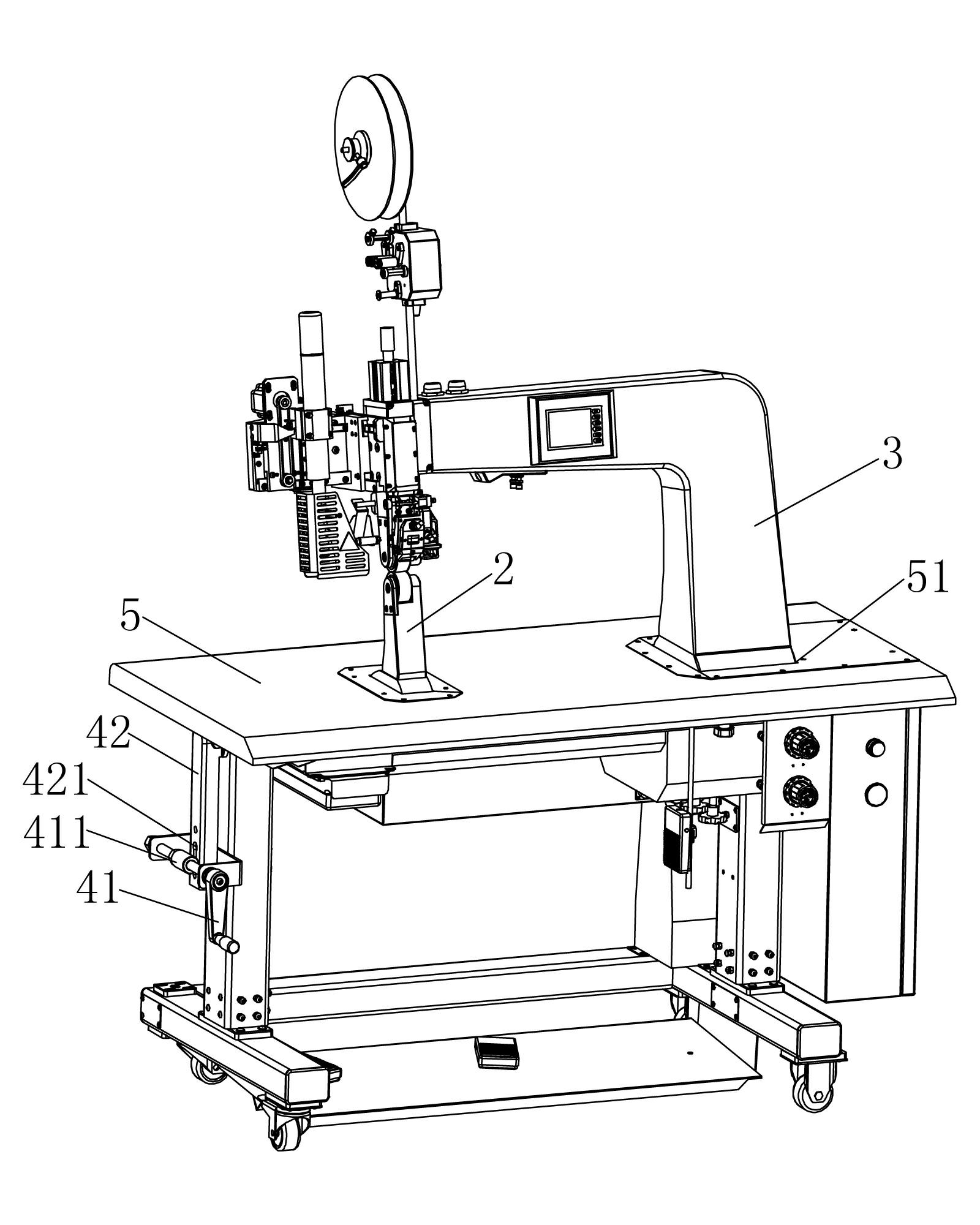

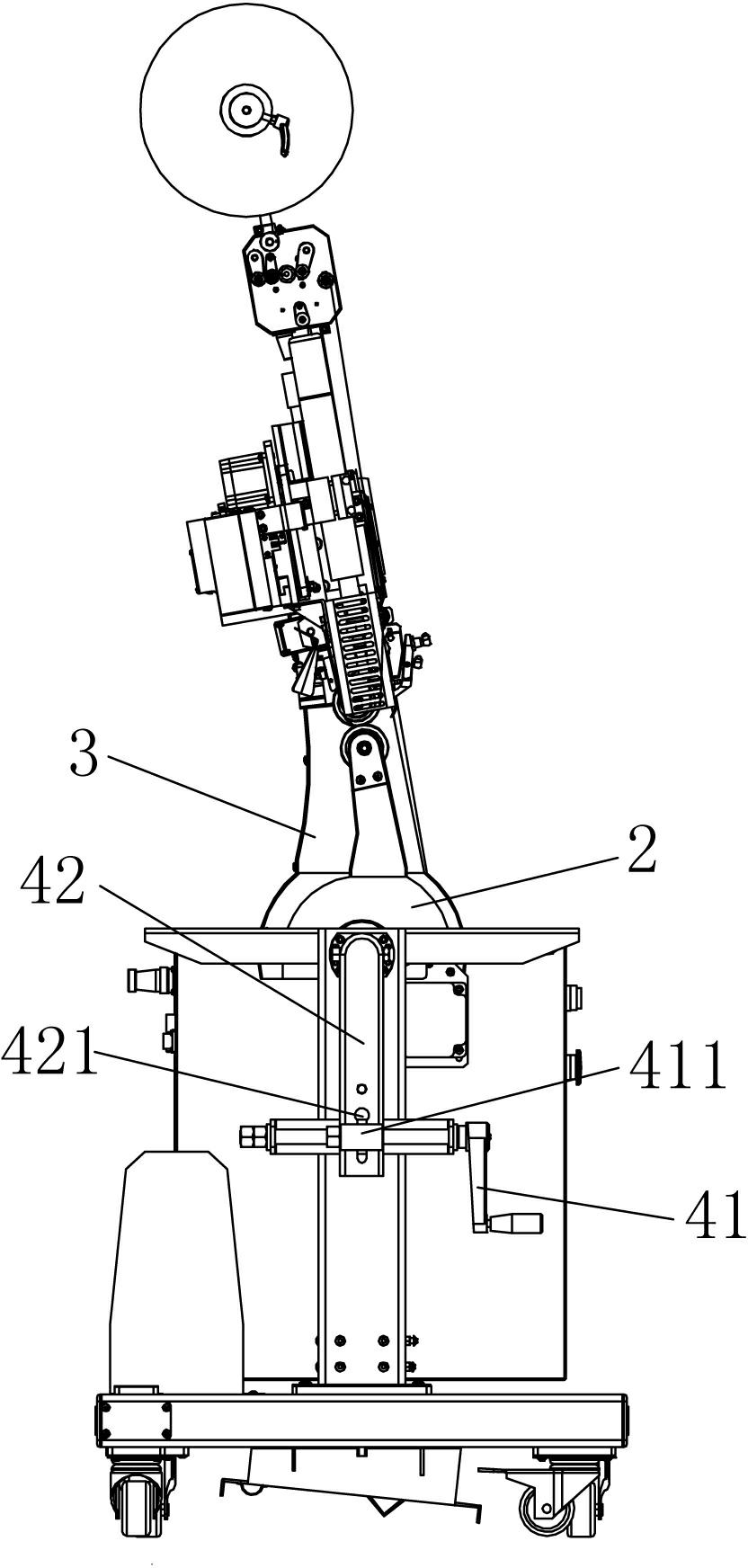

[0016] refer to figure 1 , figure 2 , image 3 , a rotary structure of a curved ruler and a lower column of a hot air seam sealing machine of the present invention, including a frame 1, a lower column fixing seat 2 and a curved ruler fixing seat 3, and also includes a rotating main shaft 4 rotatably mounted on the frame 1, The curvilinear fixed base 3 is installed on the rotating main shaft 4, and the lower column fixing base 2 is rotatably installed on the rotating main shaft 4.

[0017] In order to make the lower column fixing seat 2 on the rotating spindle 4 adjustable, one side of the lower column fixing seat 2 is provided with a lower column fixing seat clamp 21 that can clamp or loosen the rotating spindle 4 .

[0018] Further, the lower column fixing seat clamp 21 is provided with an axially extending clearance cut, and is provided with a corresponding locking bolt 211, so that the lower column fixing seat clamp 21 has a certain degree of elasticity, and the locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com