Underwater sealing wall penetrating structure

A wall-penetrating and sealing plug technology, which is applied in the direction of pipes, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of relying on large equipment, long time consumption, complicated process, etc., and achieves wide applicability and simplifies the process of operation , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] The present invention designs a wall-penetrating structure that can be applied underwater to realize the underwater photoelectric composite cable from being sealed in the water and penetrating into the underwater sealed cabin. Watertight inside and outside, can be easily installed and disassembled. The specific structure is:

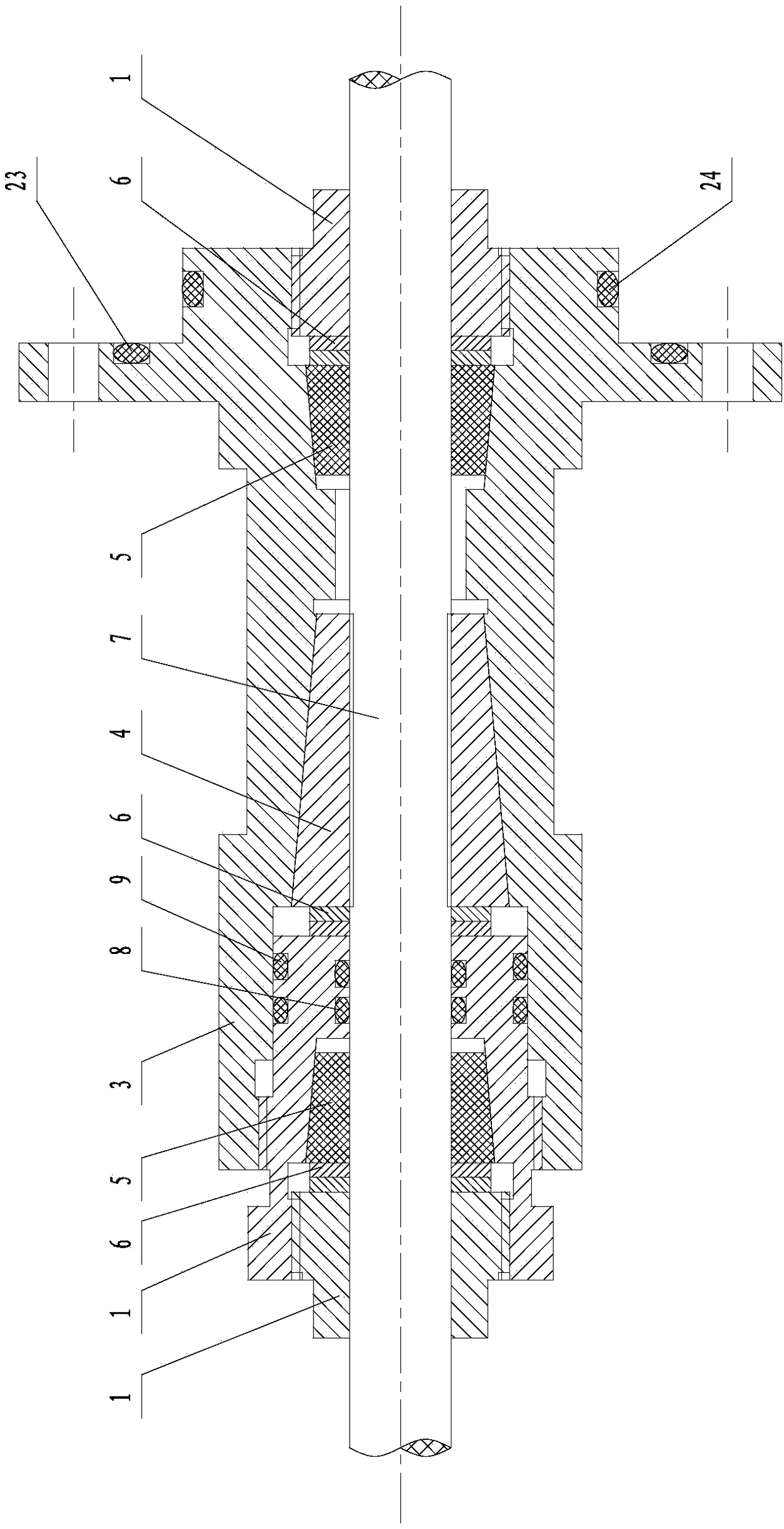

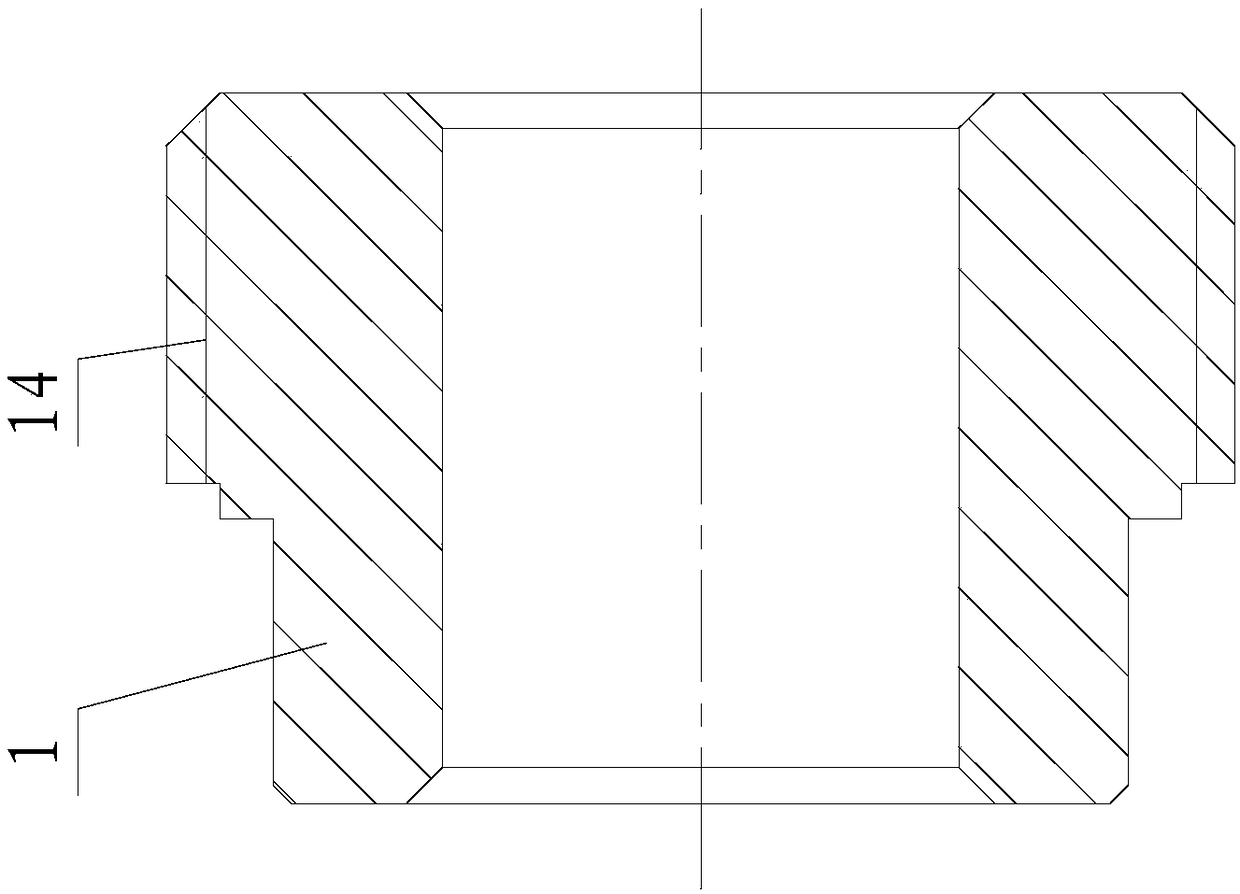

[0036] Such as figure 1 As shown, the present invention comprises sealing screw sleeve 1, compression screw sleeve 2, wall-piercing sleeve 3, compression wedge 4, sealing plug 5 and adjusting gasket 6, wherein the flange 18 at one end of wall-piercing sleeve 3 is connected to the underwater The airtight cabin body is sealed and connected, and the end is provided with a sealing plug 5 that is in sealing contact with the inner wall of the wall sleeve 3, and the end is threaded with a sealing screw sleeve 1; the other end of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com