Determination method of steel coil surface defects based on distribution characteristics of surface defects

A determination method and defect distribution technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as lack of inspection information and production information system applications, and achieve the effect of improving efficiency and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

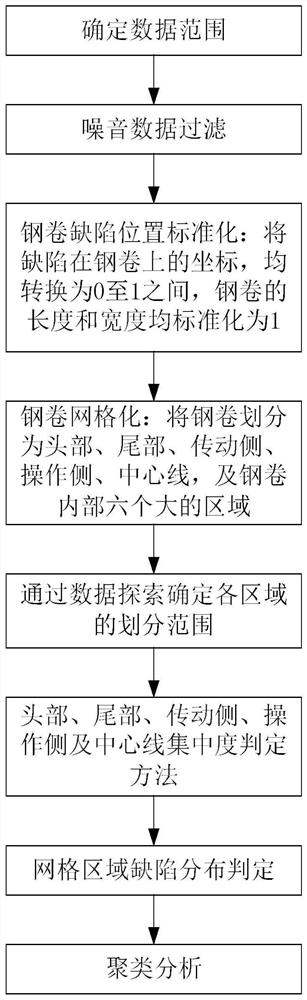

[0038] Such as figure 1 As shown, the method for judging the surface defects of the steel coil based on the distribution characteristics of the surface defects of the present invention comprises the following steps:

[0039] Step 1, determine the data range;

[0040] Step 2, noise data filtering;

[0041] Step 3. Standardization of the defect position of the steel coil: the coordinates of the defect on the steel coil are converted to between 0 and 1, and the length and width of the steel coil are both standardized to 1;

[0042] Step 4, steel coil meshing: divide the steel coil into head, tail, transmission side, operation side, center line, and six large areas inside the steel coil (there are overlaps between the areas);

[0043] Step 5. Determine the division scope of each region th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com