Pipe cleaning equipment for tunnel construction

A technology for cleaning equipment and tunnel construction, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of poor cleaning effect and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

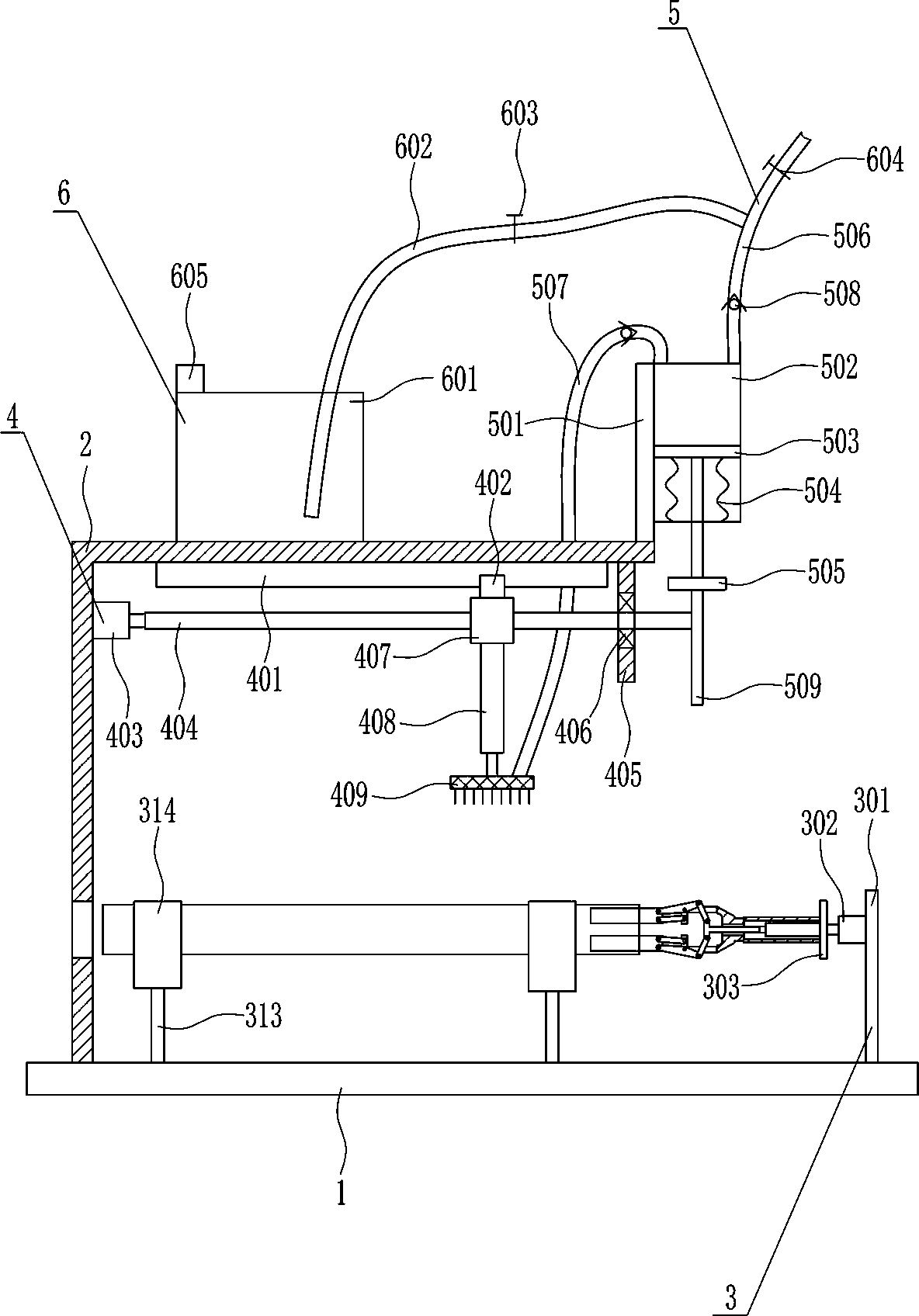

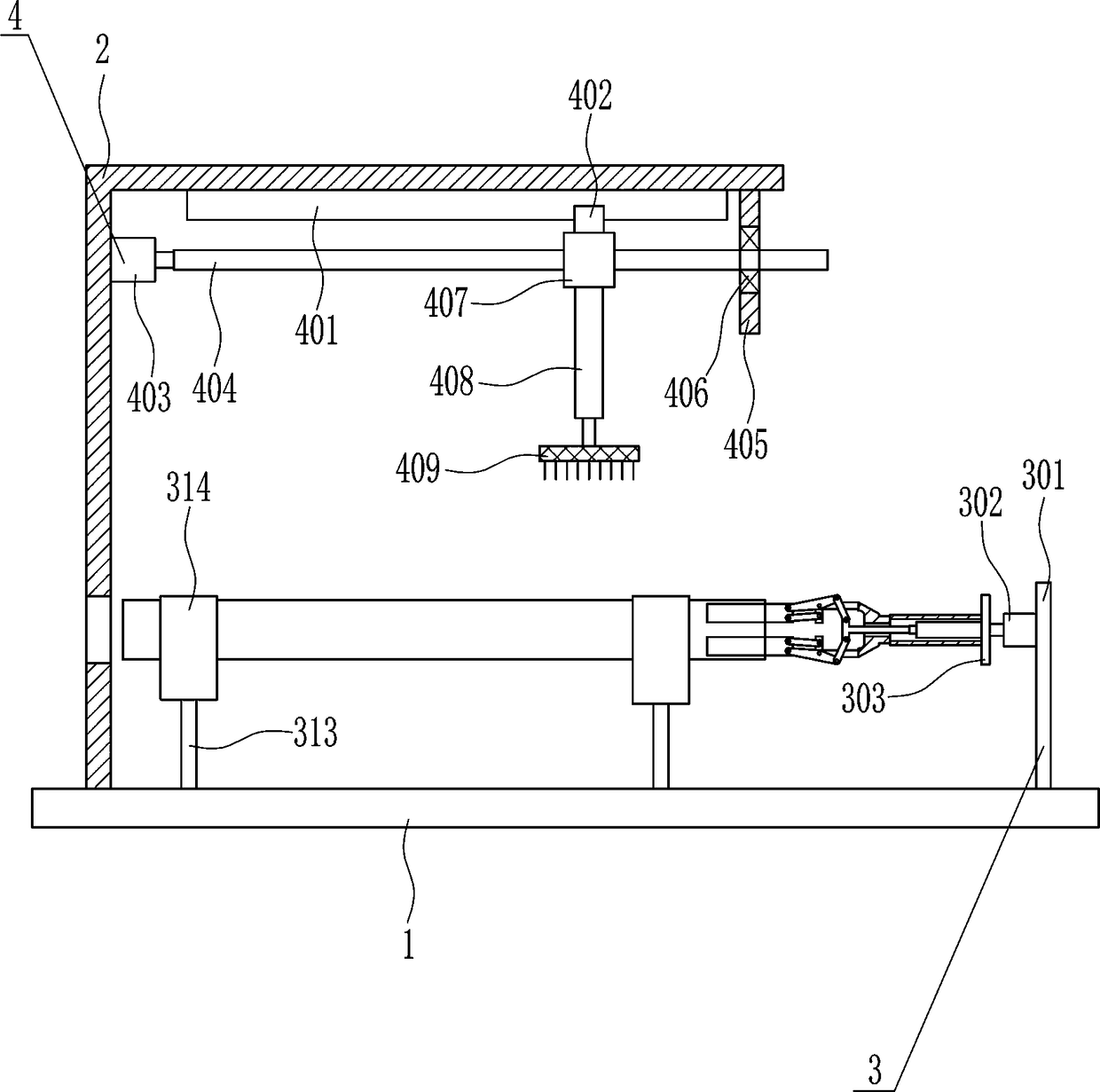

[0032] A pipe cleaning equipment for tunnel construction, such as Figure 1-6 As shown, it includes a bottom plate 1, a 7-type plate 2, a rotating device 3 and a scrubbing device 4. The left side of the top of the bottom plate 1 is connected with a 7-type plate 2, and the top of the 7-type plate 2 is equipped with a scrubbing device 4, and the top of the bottom plate 1 is installed with a The rotating device 3 and the brushing device 4 are located directly above the rotating device 3 .

Embodiment 2

[0034] A pipe cleaning equipment for tunnel construction, such as Figure 1-6 As shown, it includes a bottom plate 1, a 7-type plate 2, a rotating device 3 and a scrubbing device 4. The left side of the top of the bottom plate 1 is connected with a 7-type plate 2, and the top of the 7-type plate 2 is equipped with a scrubbing device 4, and the top of the bottom plate 1 is installed with a The rotating device 3 and the brushing device 4 are located directly above the rotating device 3 .

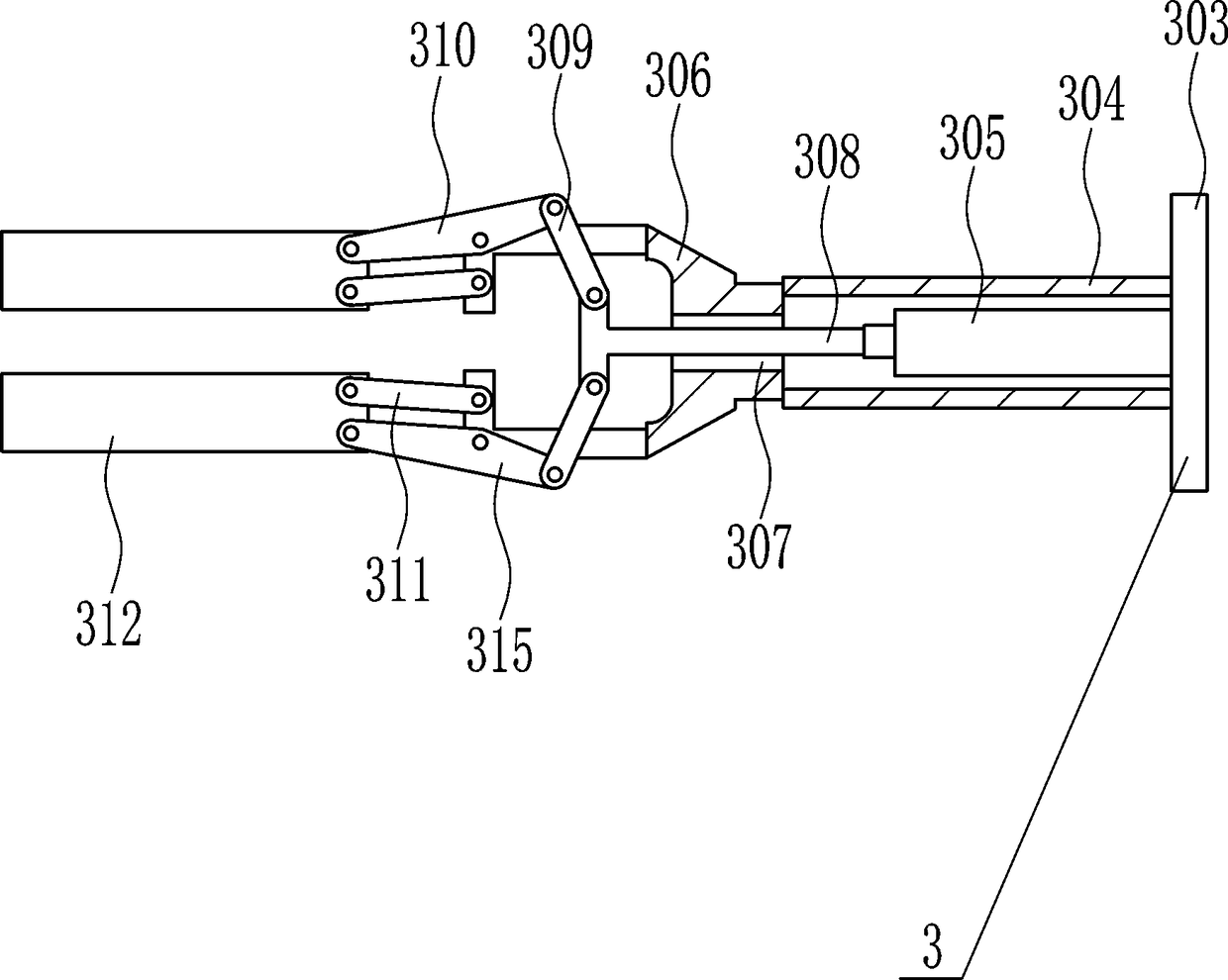

[0035] The rotating device 3 includes a first mounting plate 301, a first motor 302, a connecting plate 303, a hollow pipe 304, a first cylinder 305, an n-type bar 306, a T-shaped connecting rod 308, a first connecting rod 309, and a second connecting rod 310, the third connecting rod 311, the fixed rod 312, the support rod 313, the u-shaped block 314 and the fourth connecting rod 315, the top of the bottom plate 1 is symmetrically connected with the support rod 313, and the tops of the two su...

Embodiment 3

[0037] A pipe cleaning equipment for tunnel construction, such as Figure 1-6 As shown, it includes a bottom plate 1, a 7-type plate 2, a rotating device 3 and a scrubbing device 4. The left side of the top of the bottom plate 1 is connected with a 7-type plate 2, and the top of the 7-type plate 2 is equipped with a scrubbing device 4, and the top of the bottom plate 1 is installed with a The rotating device 3 and the brushing device 4 are located directly above the rotating device 3 .

[0038] The rotating device 3 includes a first mounting plate 301, a first motor 302, a connecting plate 303, a hollow pipe 304, a first cylinder 305, an n-type bar 306, a T-shaped connecting rod 308, a first connecting rod 309, and a second connecting rod 310, the third connecting rod 311, the fixed rod 312, the support rod 313, the u-shaped block 314 and the fourth connecting rod 315, the top of the bottom plate 1 is symmetrically connected with the support rod 313, and the tops of the two su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com