A stern energy-saving device applied to water-jet propulsion high-speed ships

A water-jet propulsion and energy-saving device technology, which is applied in the direction of hull, ship construction, hull design, etc., can solve the problems of horizontal and vertical instability, limited drag reduction effect, non-adjustable angle, etc., and achieve the effect of improving comprehensive economic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

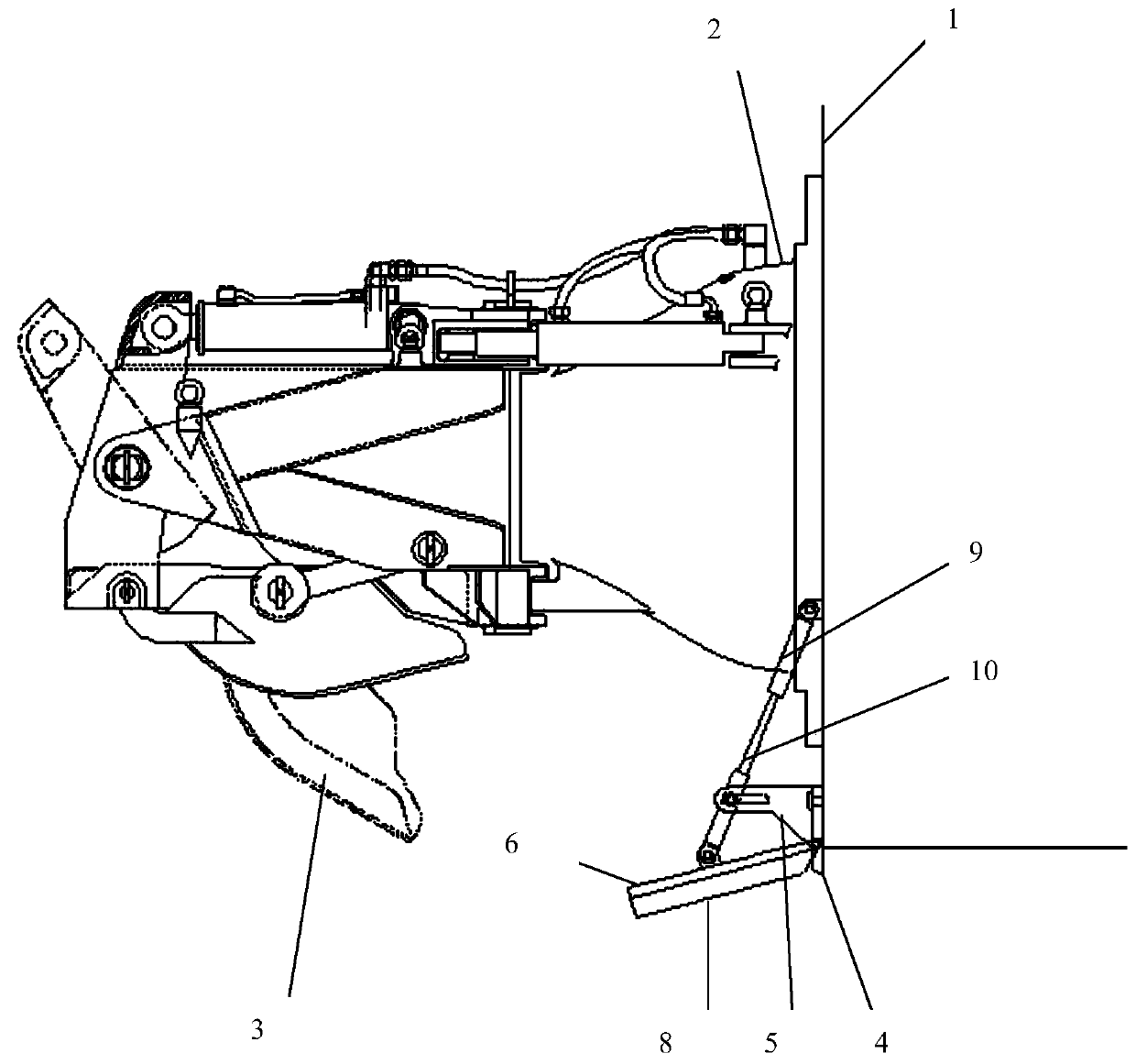

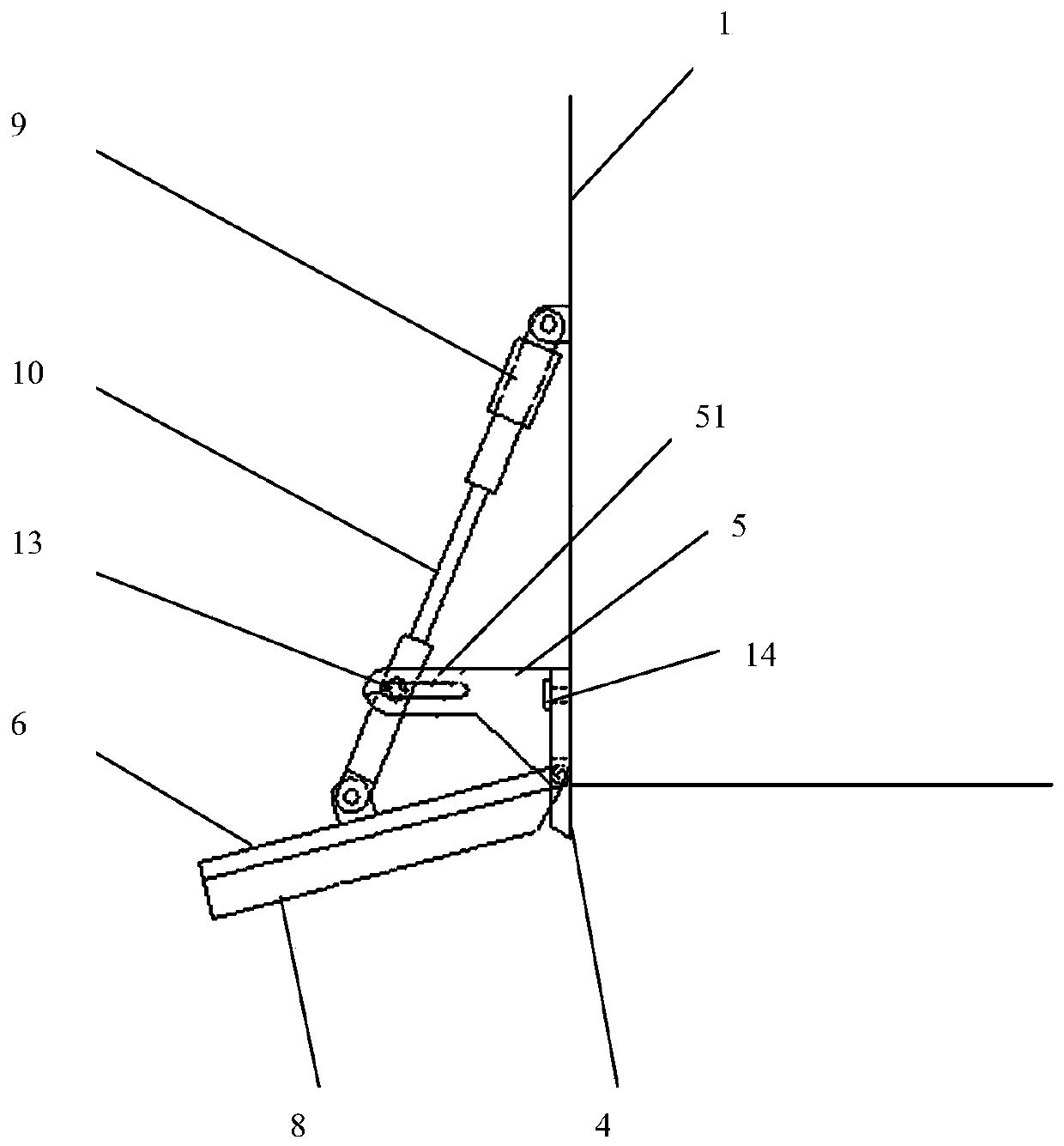

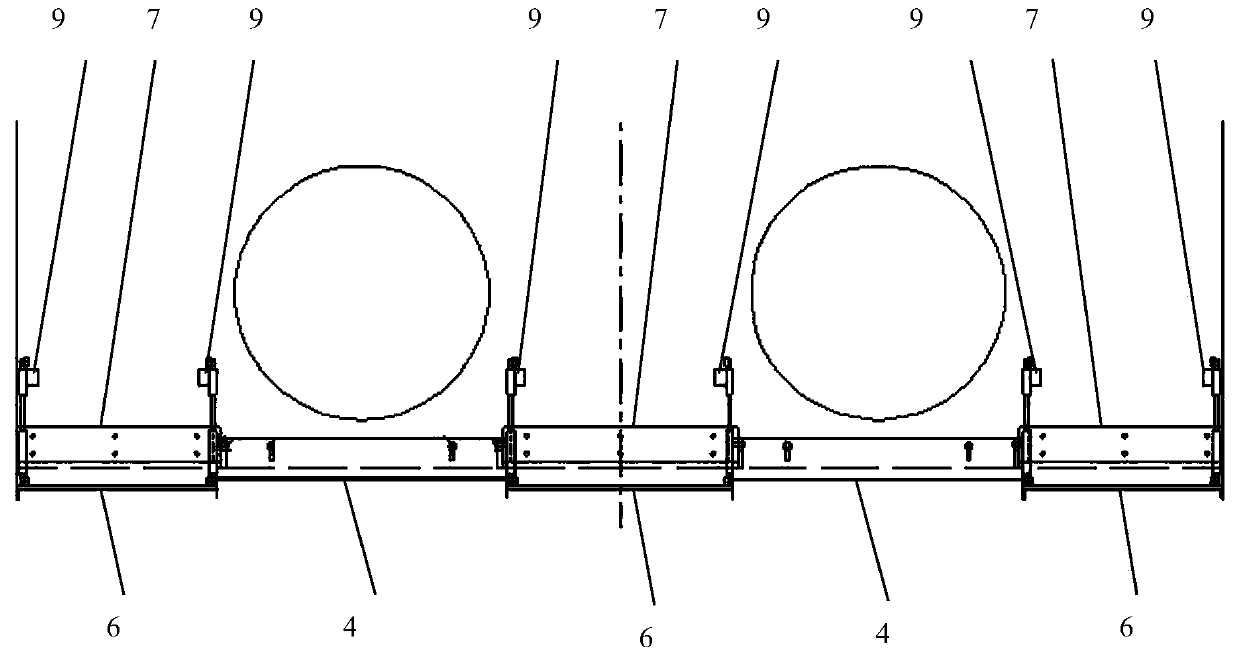

[0034] Figure 4 It is the front view of the junction of the cutoff plate and the wave suppression plate of the stern energy-saving device applied to the water jet propulsion high-speed ship of the present invention, Figure 5 It is a top view of the junction of the cutoff plate and the wave suppression plate of the stern energy-saving device applied to the water-jet propelled high-speed ship of the present invention.

[0035] In further embodiments of the present invention, see Figure 4 and Figure 5 As shown, the positioning plate 7 is provided with a slot 15 at one end close to the cut-off plate 4, and one end of the cut-off plate 4 is arranged in the slot 15, so that the cut-off plate 4 can only slide vertically and cannot slide horizontally.

[0036] In further embodiments of the present invention, please continue to refer to image 3 shown in the image 3 The other ends of the two wave-pressing plates 6 at the middle left end and the right-hand end are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com