Computer-based quality management testing device

A detection device and quality management technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inconvenient measurement, insufficient accuracy of detection data, and insufficient enthusiasm, so as to increase the density of strict inspection, novel design structure, The effect of preventing flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

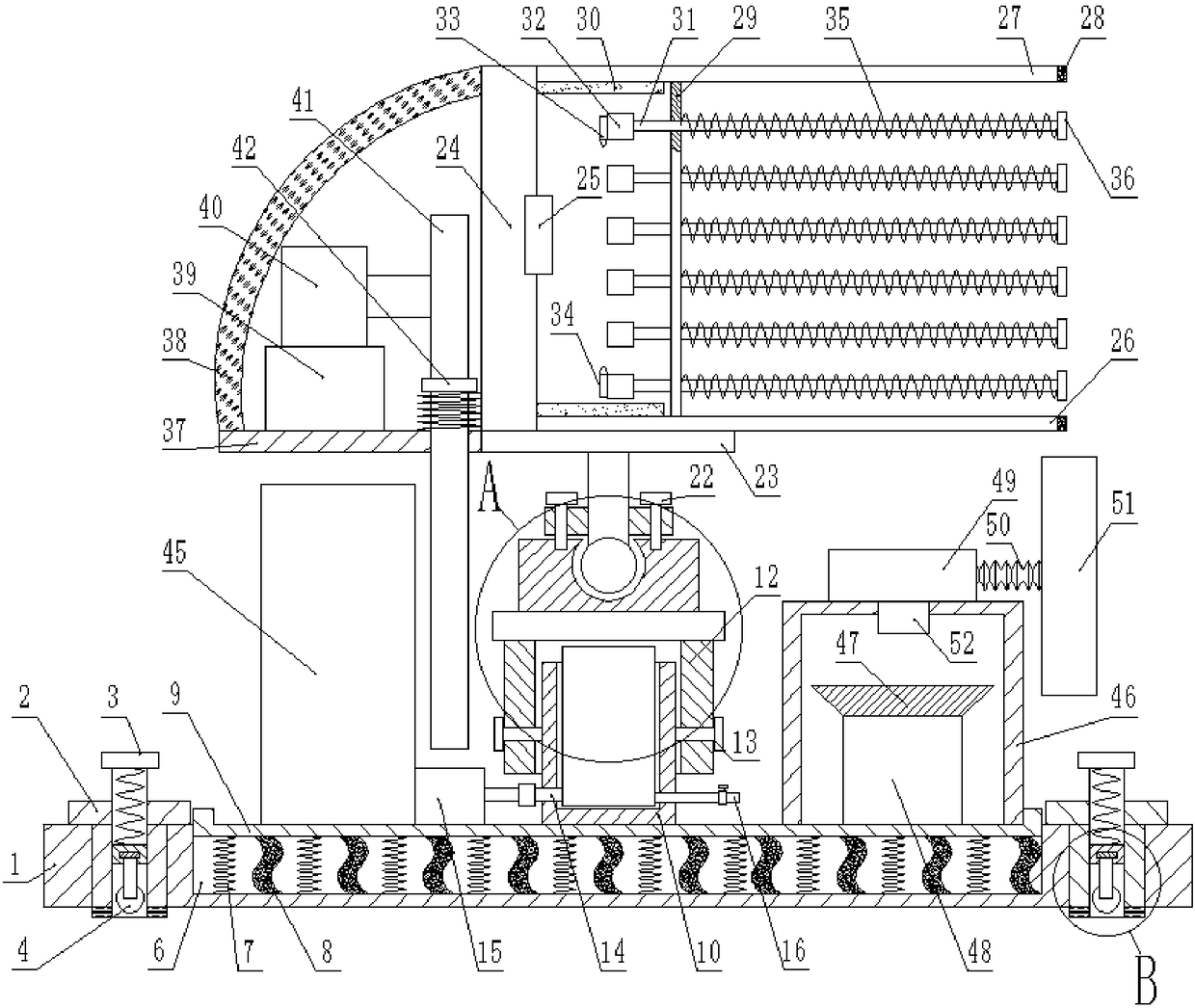

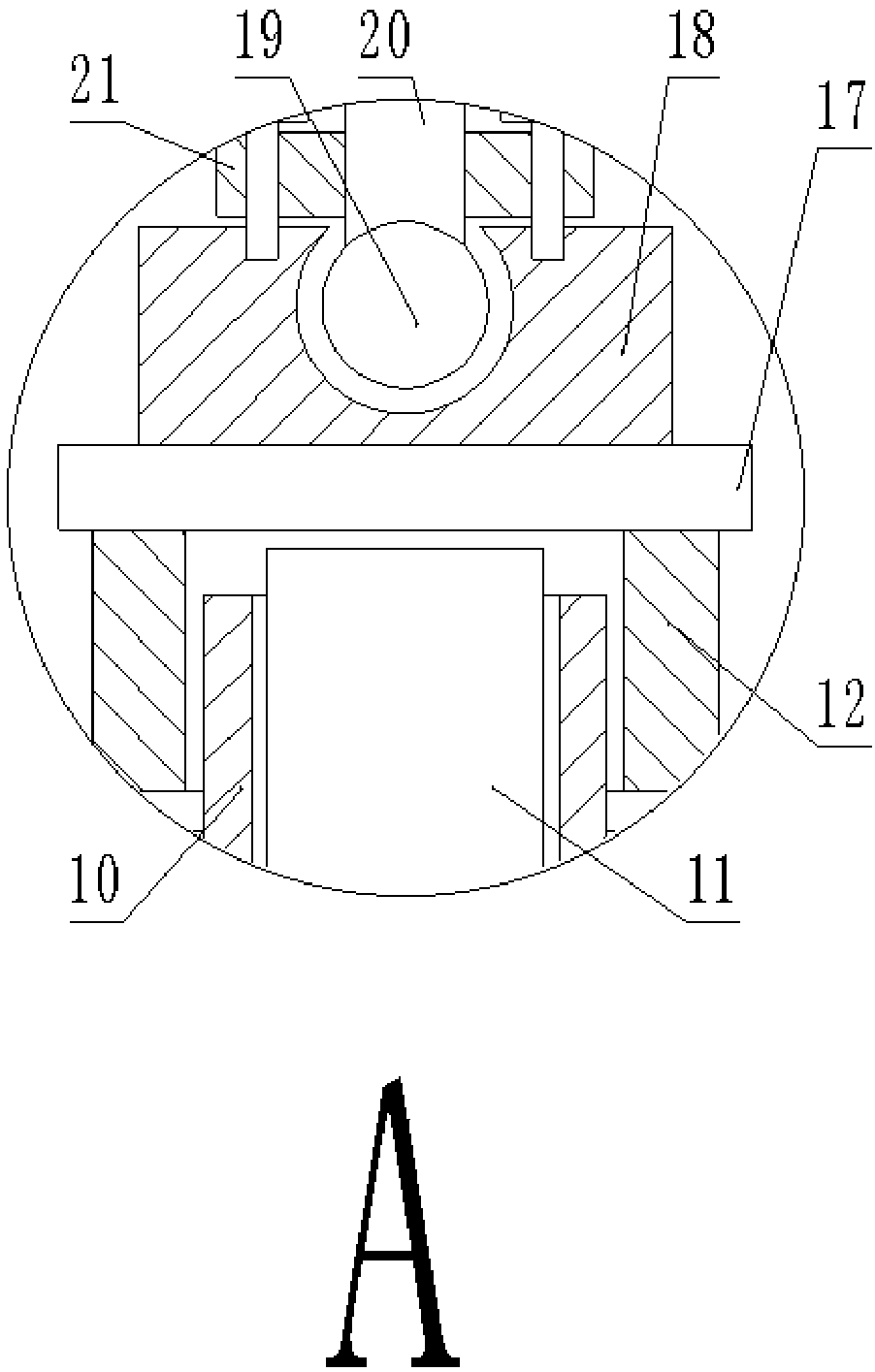

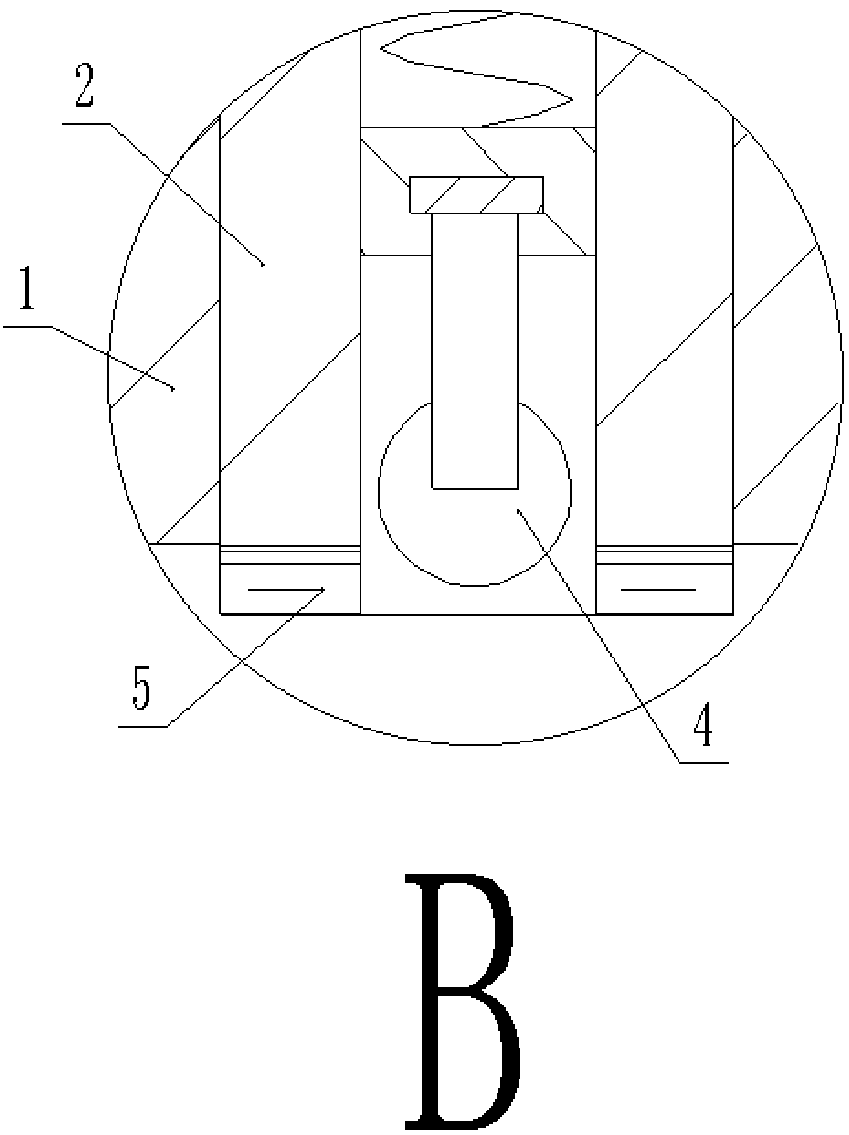

[0021] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a computer-based quality management testing device includes a base 1, and two T-shaped sleeves 2 are embedded and fixed on the edge sides of both sides of the base 1, and a screw 3 is screwed into the T-shaped sleeve 2. , the bottom end of the screw 3 is fixedly connected with the universal wheel 4 through the connecting block, the bottom end of the T-shaped sleeve 2 is fixedly attached with a non-slip rubber pad 5, and the center of the base 1 is fixedly provided with a groove 6, so A plurality of shock-absorbing springs 7 and rubber hoses 8 are fixed in the groove 6, and a rubber hose 8 is arranged between every two shock-absorbing springs 7, and the tops of the shock-absorbing springs 7 and the rubber hose 8 are fixed. A U-shaped bottom plate 9 is provided, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com