Wheel type rotatable precision machining welding robot

A welding robot and precision machining technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of easily damaged bottom rollers, inconvenience for operators, and low service life, and achieve low cost, simple design structure, The effect of supporting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

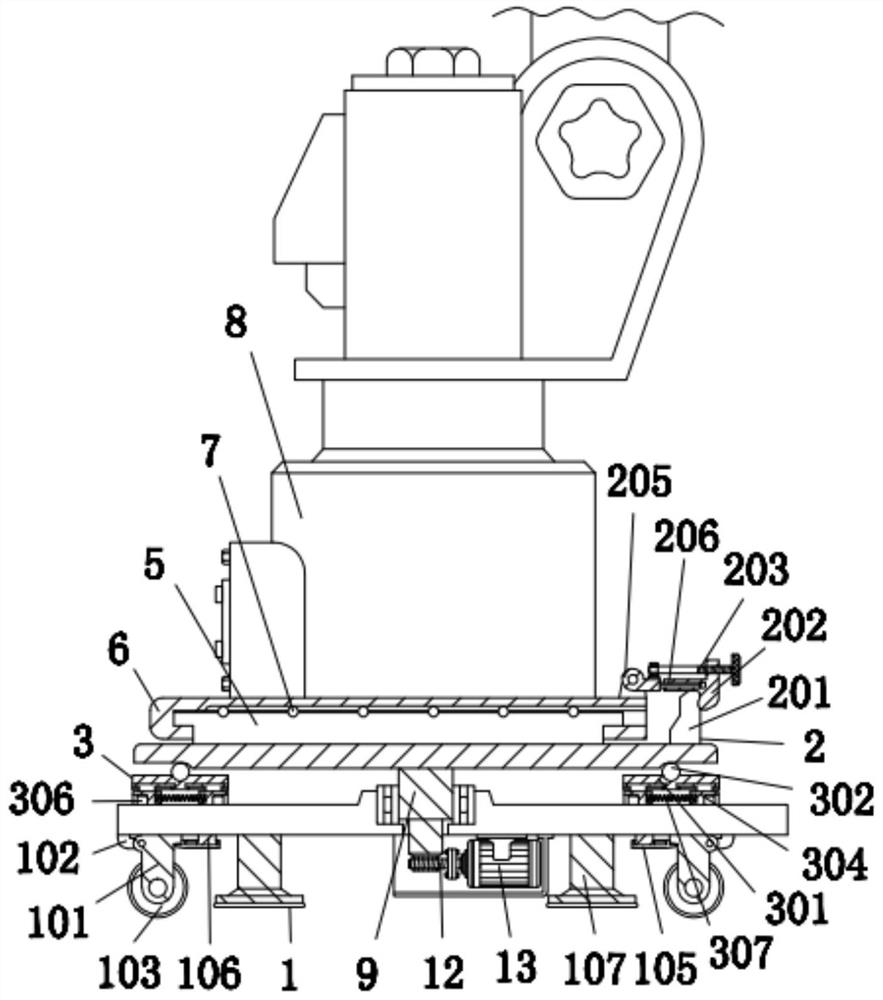

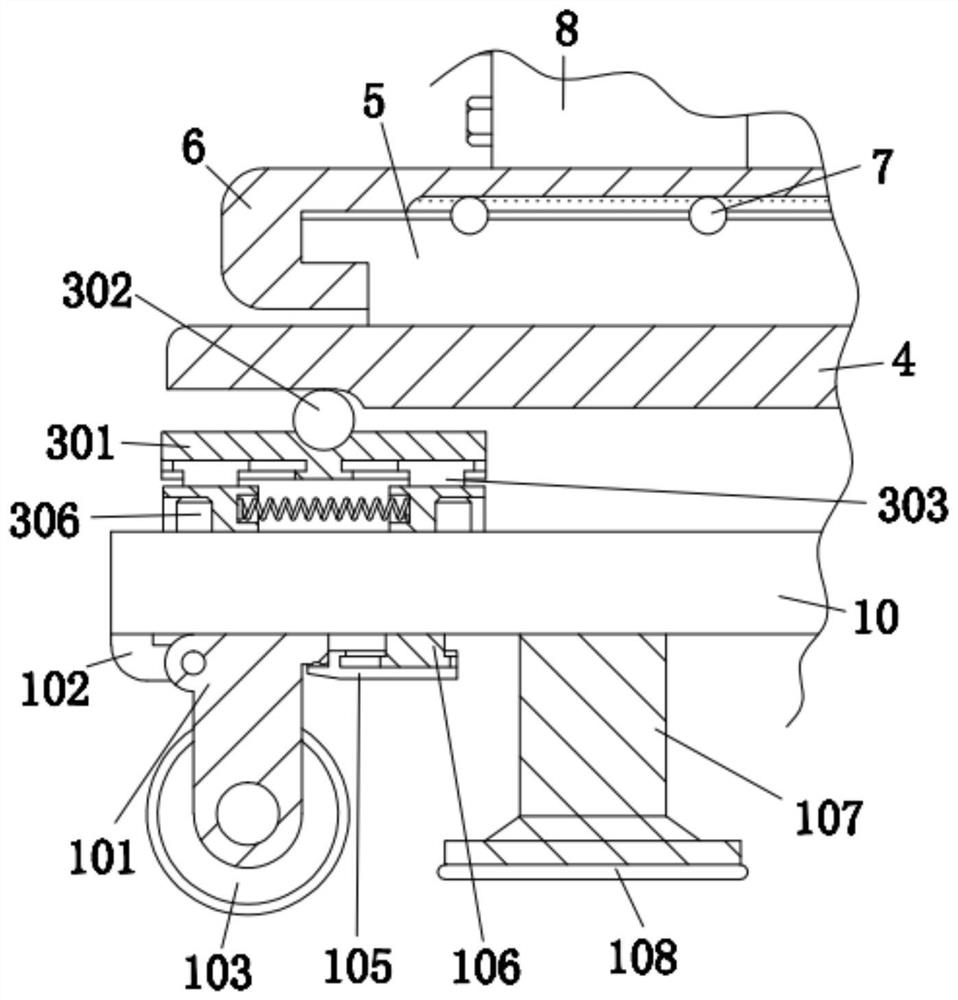

[0033]A wheeled rotatable precision machining welding robot, including a circular plate 4, the top valley of the circular plate 4 is fixedly connected with a first slide rail 5, the first slide rail 5 cooperates with the top plate 6, and the circular plate 4 and the welding robot 8 To limit the position, the upper part of the outer wall of the first slide rail 5 is slidingly clamped with the top plate 6, and the top of the top plate 6 is fixedly connected with the welding robot 8. The welding robot 8 is a compact processing welding robot. The specific model is not limited and meets the needs of use. That is, the top inner surface of the first slide rail 5 is clearance-fitted with the first steel ball 7, and the first steel ball 7 cooperates with the groove 15 to reduce the friction between the top plate 6 and the first slide rail 5, and the top of the first steel ball 7 The groove 15 is movably connected with the top of the inner wall of the top plate 6, the bottom of the circu...

Embodiment 2

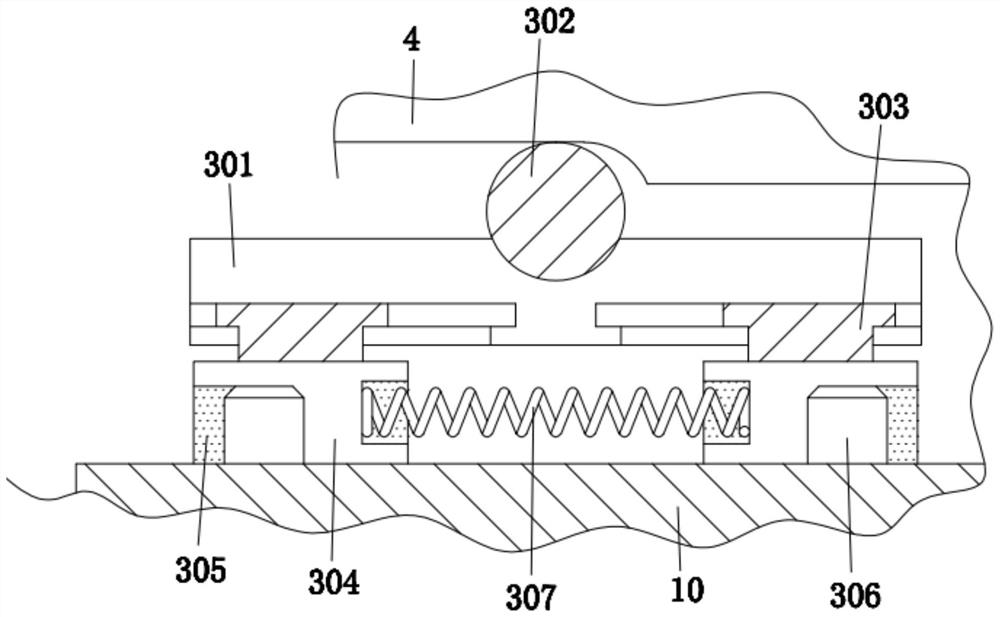

[0035] As an option, see Figure 1-3 , a wheeled rotatable precision machining welding robot, the left and right sides of the bottom of the circular plate 4 are provided with a support device 3, the support device 3 includes a square rod 301, a second steel ball 302, a third slide rail 303, a base 304, and an opening 305 , a short rod 306 and a spring 307, the top inner surface of the square rod 301 has a gap with a second steel ball 302, the second steel ball 302 supports the other side rod 301 and the circular plate 4, and the top of the second steel ball 302 is in contact with the circular plate 4 The top of the square rod 301 is attached to the top, and the left and right sides of the bottom inner wall of the square rod 301 are slidingly connected with the third slide rail 303. The third slide rail 303 plays a role in connecting the base 304 and the square rod 301. The third slide rail 303 The bottom of the base 304 is fixedly connected with a base 304, the bottom of the b...

Embodiment 3

[0038] As an option, see figure 1 and 6 , a wheeled rotatable precision machining welding robot, the right side of the top plate 6 is provided with a fixing device 2, the fixing device 2 includes a block 201, a hook 202, a threaded rod 203, a hand wheel 204, a first support 205, a cross bar 206, The second support 207, the bottom of the clamping block 201 is fixedly connected with the top right side of the bottom plate 4, the clamping block 201 cooperates with the hook 202 to fix the top plate 6, the upper right side of the clamping block 201 is clamped with a hook 202 , the left side of the inner wall of the hook 202 is fitted with a cross bar 206, and the left end of the cross bar 206 is fixedly connected with a first support 205, and the first support 205 and the second support 207 cooperate to limit the cross bar 206. , the left side of the bottom of the first support 205 is connected with the second support 207 through the pin shaft rotation, the bottom of the second sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com