Buffer type liftable machine tool for precision instrument machining

A technology of precision instruments and machine tools, used in metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., can solve the problems of complex lifting structure, inconvenient maintenance and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

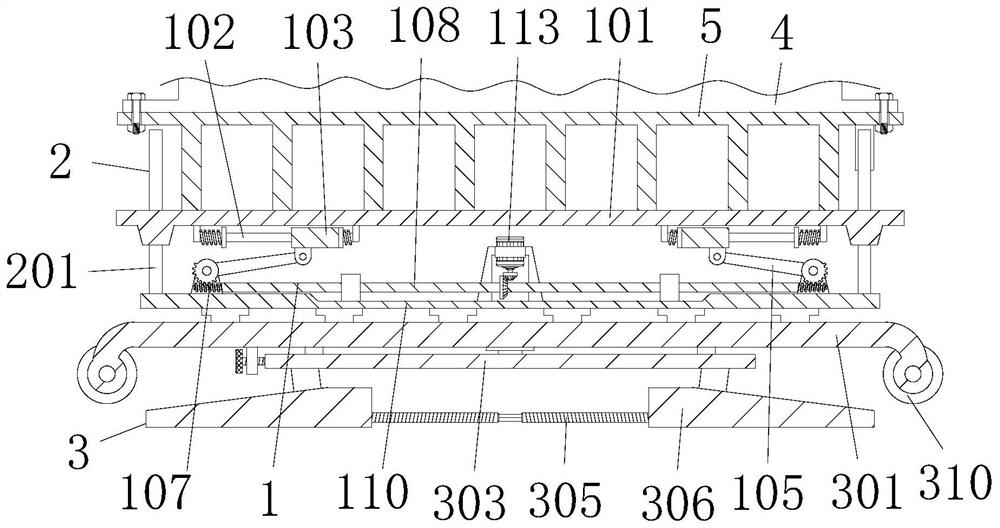

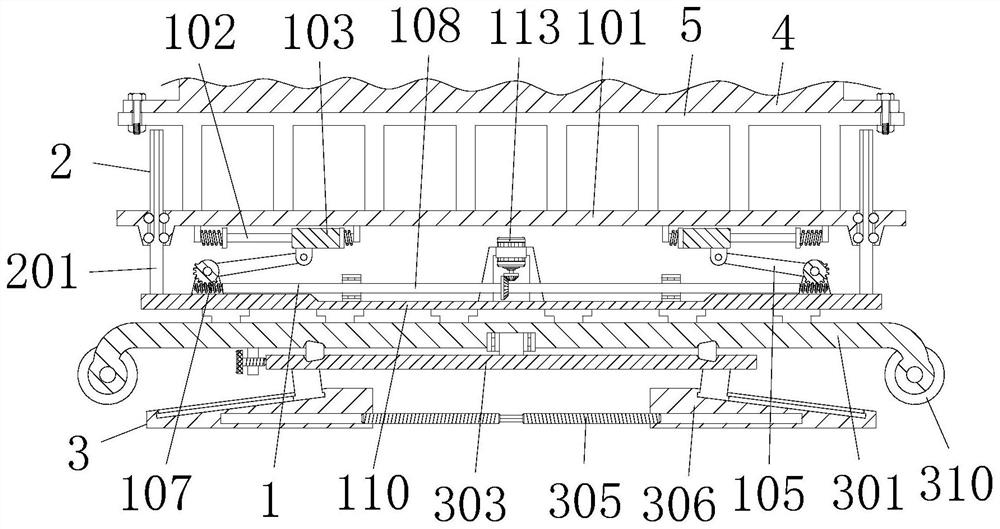

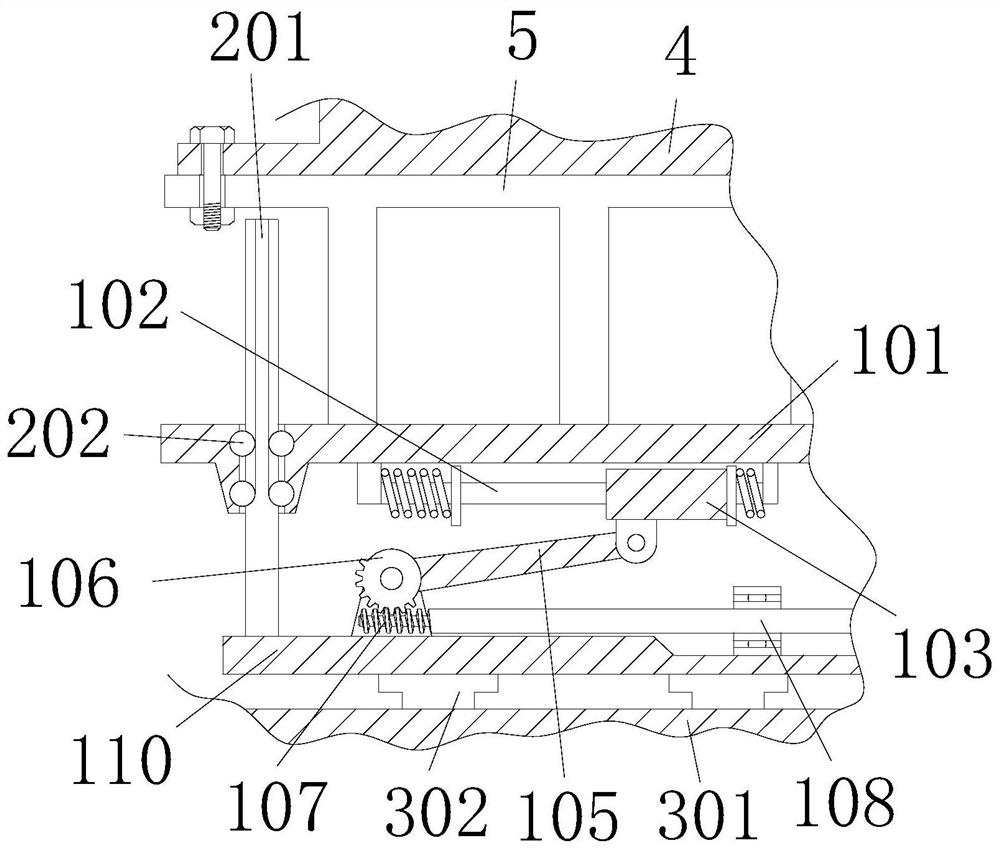

[0038] A buffer type liftable machine tool for precision instrument processing, including a machine tool 4. The machine tool 4 is a machine tool for precision instrument processing. The specific model is not limited, as long as it meets the needs of the operation. The bottom of the machine tool 4 is fixedly connected with a bracket 5, and the bracket 5 There is a lifting device 1 below, and the lifting device 1 includes a horizontal plate 101, a limit column 102, a first slider 103, a first support 104, a diagonal rod 105, a worm wheel 106, a worm 107, a long rod 108, and a second support. 109, top plate 110, the first bevel gear 111, the second bevel gear 112 and the servo motor 113, the bottom left and right sides of the horizontal plate 101 are all provided with the first slide block 113, and the first slide block 103 is movably sleeved at the limit On the positioning column 102, the two ends of the limiting column 102 are provided with a connecting plate 1022, the connectin...

Embodiment 2

[0041] As an option, see Figure 1-3 , a liftable machine tool for precision instrument processing, a limit device 2 is provided on the left and right sides of the horizontal plate 101, the limit device 2 includes a vertical rod 201 and a steel ball 202, the outer wall of the vertical rod 201 runs through the horizontal plate 101, and the outer wall of the vertical rod 201 The left and right sides are movably connected with steel balls 202 through grooves. The steel balls 202 reduce the friction between the vertical bar 201 and the horizontal plate 101. The outer wall of the steel ball 202 is matched with the inner wall groove of the horizontal plate 101. The bottom of the vertical bar 201 is in contact with the top plate. The tops of 110 are fastened together.

[0042] The solution in this embodiment can be selectively used in combination with the solutions in other embodiments.

Embodiment 3

[0044] As an option, see figure 1 , 2 , 3, 5 and 6, precision instrument processing with liftable machine tools, the bottom of the top plate 110 is provided with a support device 3, the support device 3 includes a square plate 301, a pole 302, a circular plate 303, a conical wheel 304, a double-ended stud 305, base 306, second slide block 307, bolt 308, riser 309 and roller 310, the top equidistant of square plate 301 is fixedly connected with strut 302, and strut 302 plays the role of support to opposite plate 301 and top plate 110, The top of the pole 302 is fixed together with the bottom of the top plate 110, the left and right ends of the bottom of the square plate 301 are rotatably connected with rollers 310, the rollers 310 facilitate the movement of the square plate 301, and the bottom of the square plate 301 is rotatably connected with a circular plate 303, the left and right sides of the top groove of the circular plate 303 are connected with conical wheels 304, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com