Hybrid power system using dual planetary line configuration

A technology of hybrid power system and double planetary row, which is applied to the arrangement of multiple different prime movers of hybrid power vehicle, power plant, and general power plant, etc., can solve the problems of power interruption, poor driving comfort, insufficient system power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

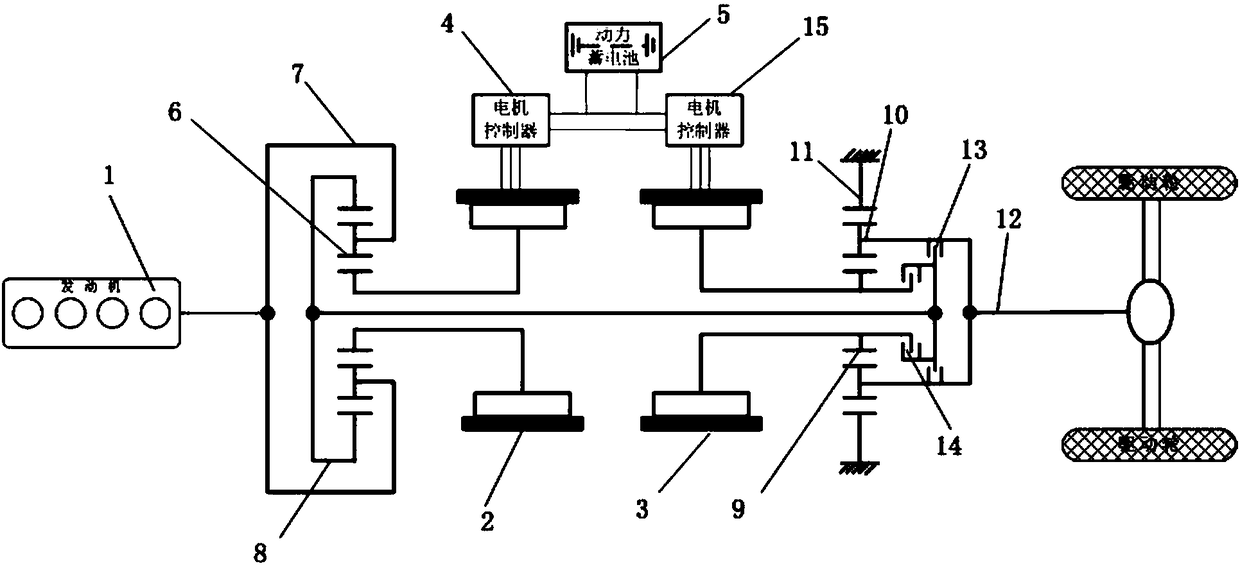

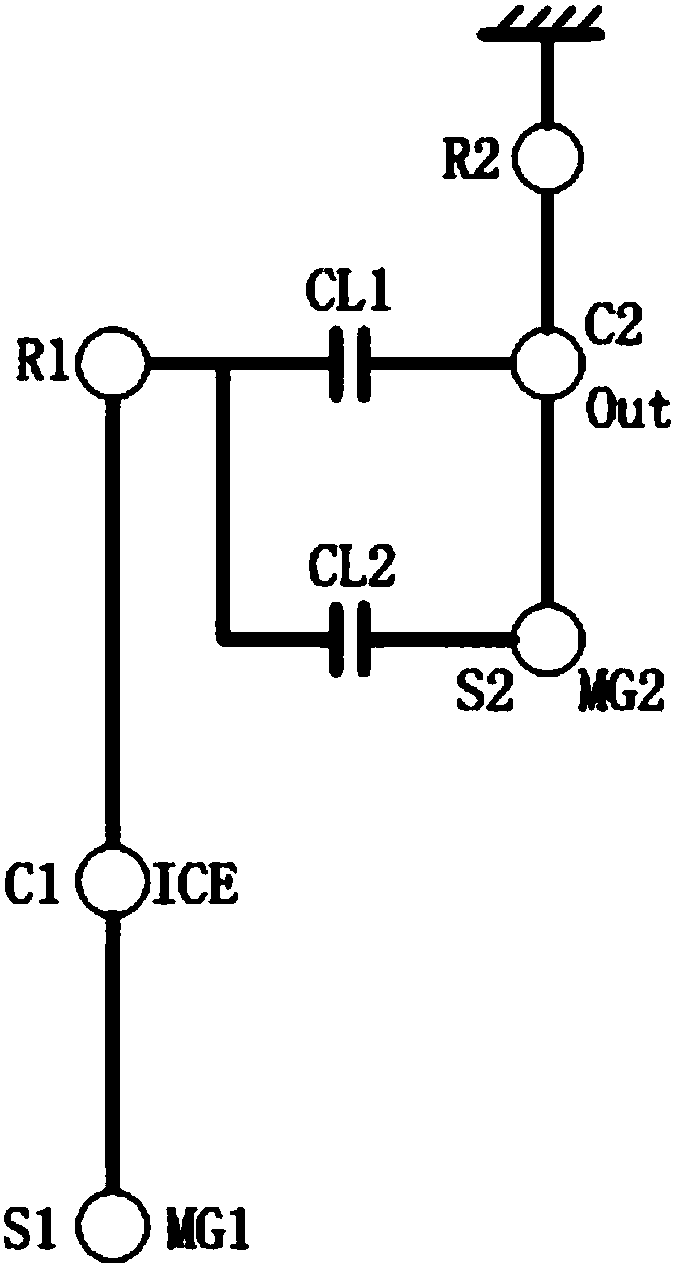

[0018] see figure 1 , with reference to figure 2 . A hybrid power system using a dual planetary row configuration of the present invention includes an engine 1, a generator 2, a main drive motor 3, an output shaft 12, a first motor controller 4, a second motor controller 15, and a power battery 5 And power coupling device, power coupling device comprises front row sun gear 6, front row planet carrier 7, front row ring gear 8, rear row sun gear 9, rear row planet carrier 10, rear row ring gear 11, second mode clutch 13 , the first mode clutch 14, wherein the front row characteristic parameter k value is k 1 , the value of the feature parameter k in the back row is k 2 .

[0019] The engine 1 is connected with the front planetary carrier 7, the generator 2 is connected with the front sun gear 6, and the main drive motor 3 is connected with the rear sun gear 9.

[0020] The front row ring gear 8 is connected with the rear row planet carrier 10 through the second mode clutch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap