Dual-motor rotating speed and torque coupling driving assembly

A technology of coupled drive and dual motors, which is applied in the direction of electric power devices, power devices, control devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

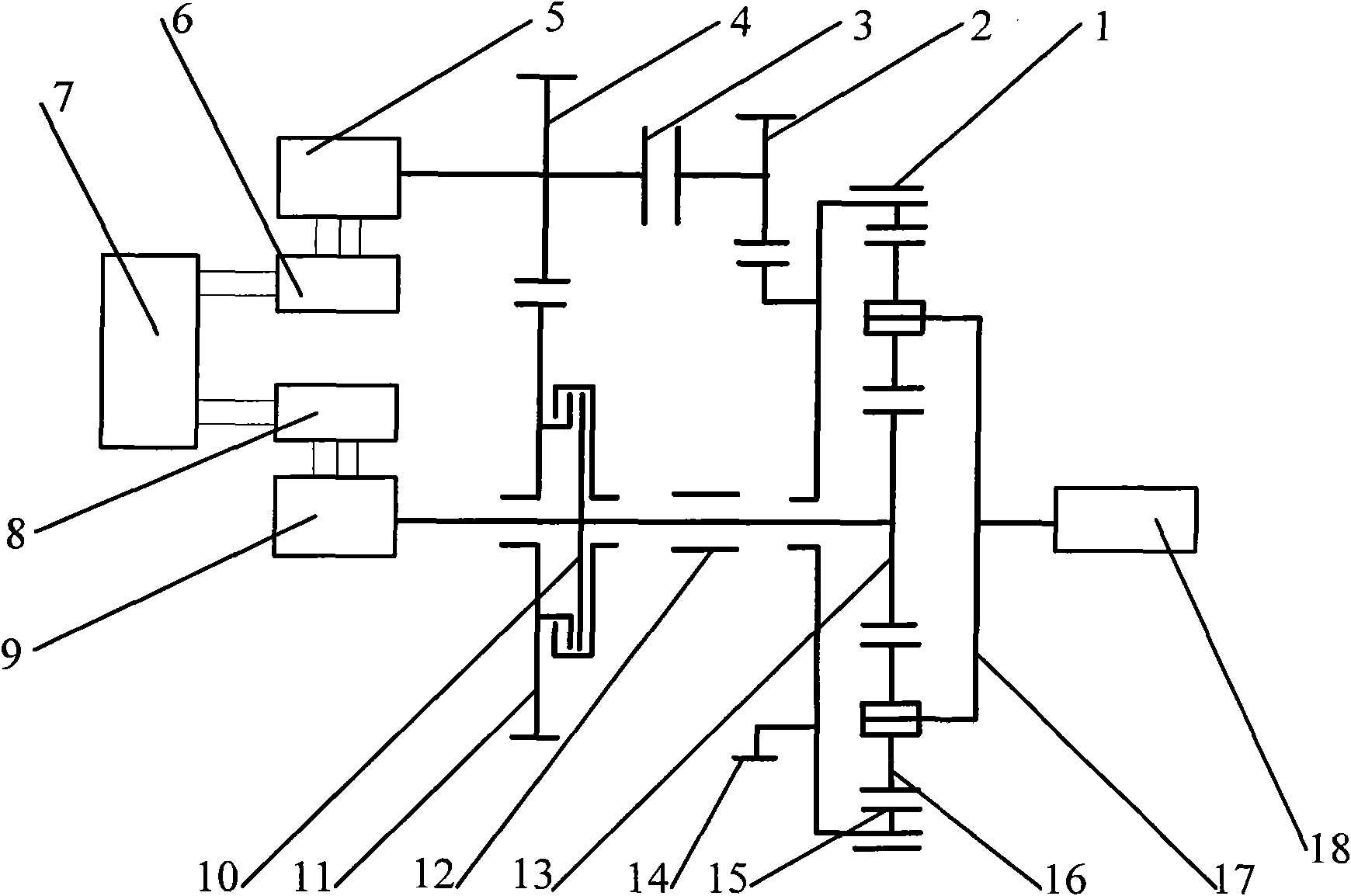

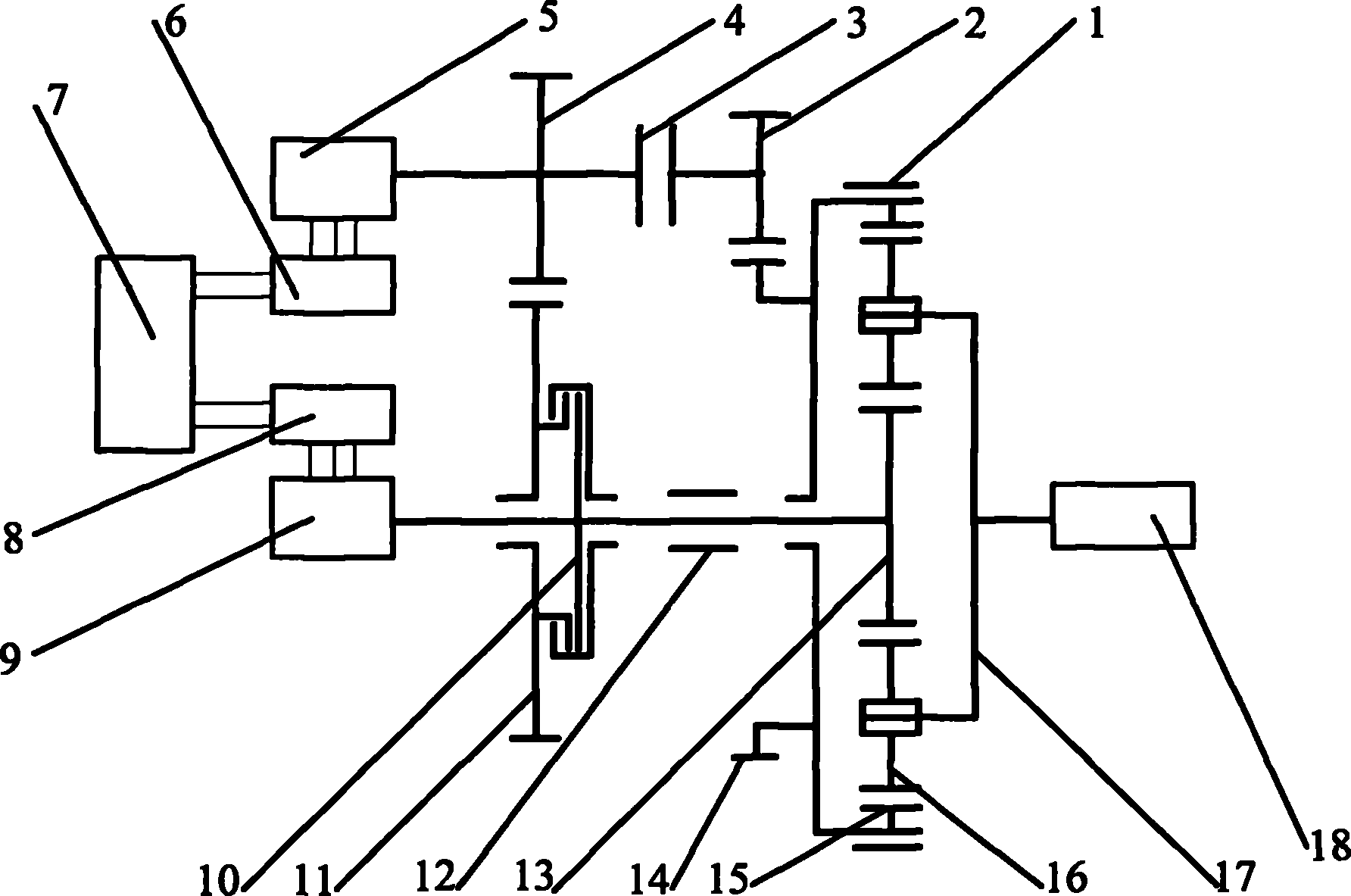

[0008] Now further illustrate in conjunction with accompanying drawing.

[0009] The present invention consists of locker 1, gear 2, clutch 3, gear 4, auxiliary motor 5, auxiliary motor controller 6, energy storage device 7, main drive motor controller 8, main drive motor 9, clutch 10, gear 11, Locker 12, sun gear 13, ring gear outer teeth 14, ring gear inner teeth 15, planetary gear 16, planet carrier 17, driving wheel 18 are formed. The main drive motor 9 and the auxiliary motor 5 are arranged on the same side of the power coupling device, and the shafts are arranged in parallel.

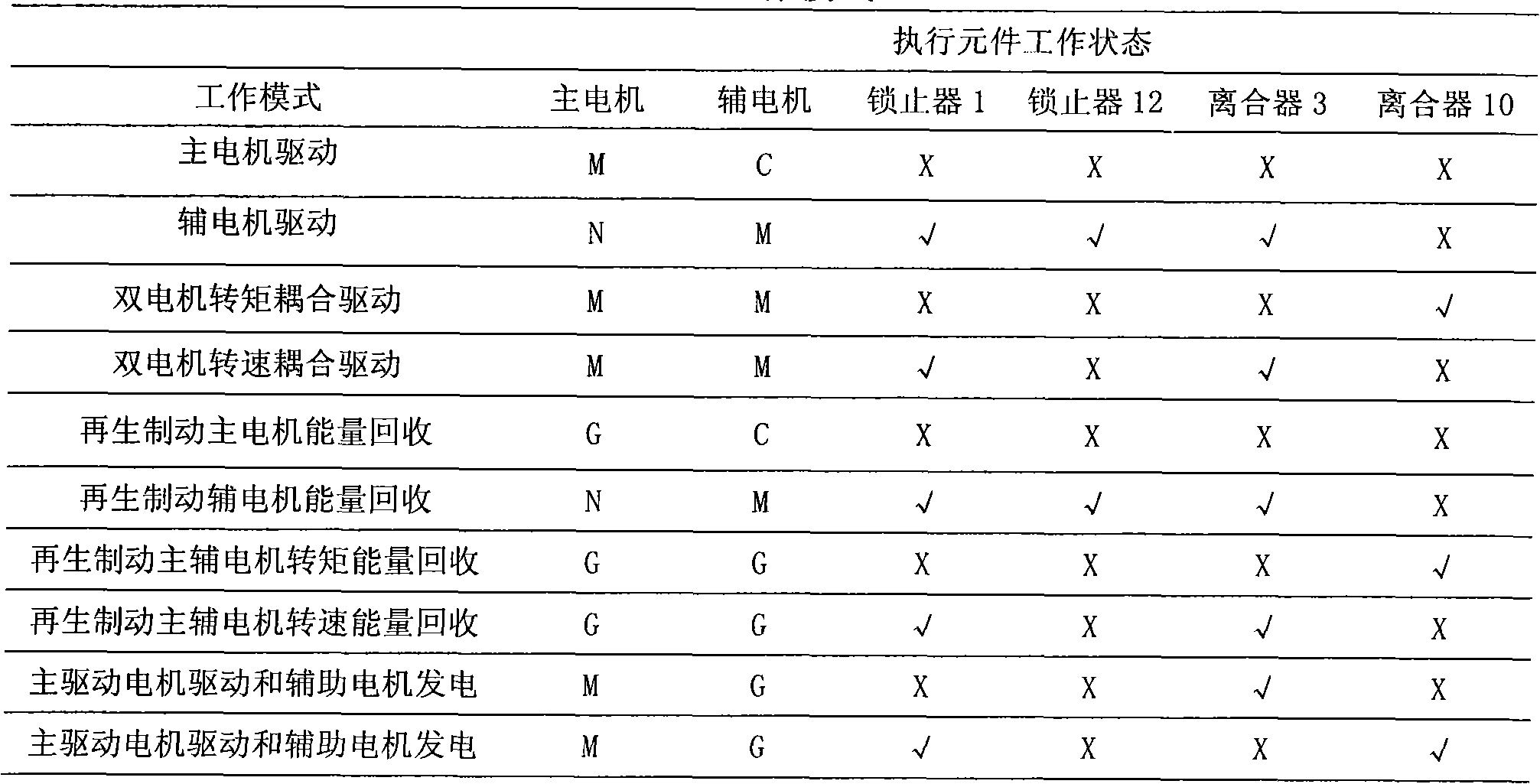

[0010] The main drive motor controller 8 controls the working state and power output of the main driving motor 9, the on-off of the power output of the main driving motor 9 is realized by controlling the locker 12, and the auxiliary motor controller 6 controls the working state and power output of the auxiliary motor 5 The on and off of the power output of the auxiliary motor 5 is specifically re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com