A method for identification of rolling bearing fault damage degree

A damage degree and rolling bearing technology, which is applied in the testing of machines/structural components, testing of mechanical components, instruments, etc., can solve the problem of difficulty in accurately describing the complexity of signal forms, insufficient ability to distinguish failure modes, and unsatisfactory identification of fault damage degrees and other problems, to achieve the effects of good practicability, improved efficiency, and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

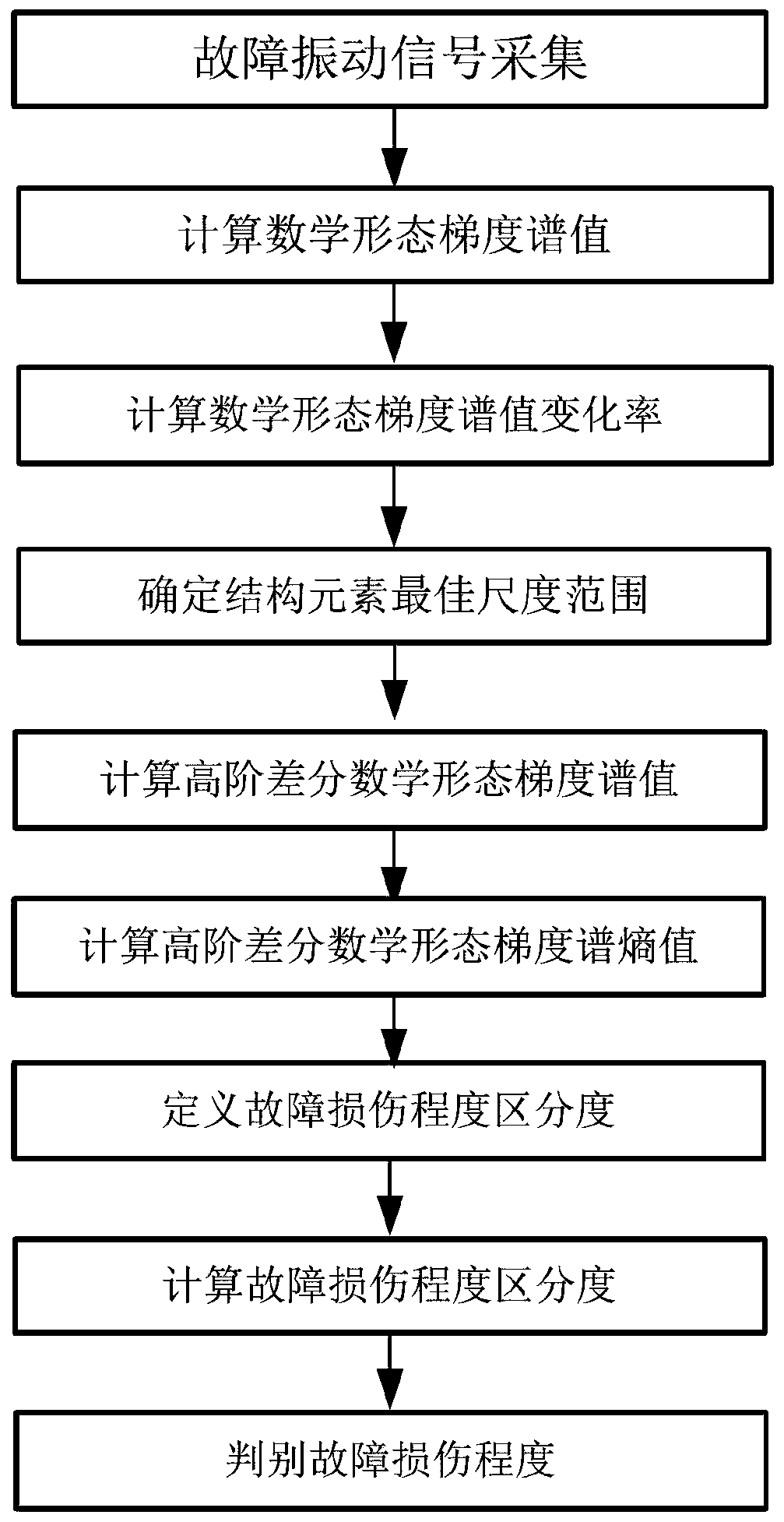

[0058] The invention provides a method for identifying the degree of damage to a rolling bearing fault, which is combined below figure 1 The schematic flow chart of the present invention is described.

[0059] Such as figure 1 As shown, the technical solution of the present invention is: a rolling bearing fault damage identification method, comprising the following steps:

[0060] Step 1, using the acceleration sensor to collect the vibration acceleration signal of the rolling bearing under the running state of the motor;

[0061] Step 2, λ is the analysis scale, change λ from 1 to 50, and calculate the mathematical form gradient spectrum value of the vibration acceleration signal measured in step 1 under different scales;

[0062] Step 3. Change λ from 1 to 50, and calculate the change rate of the mathematical form gradient spectrum value of the vibration acceleration signal measured in step 1 under different scales. The formula for the change rate of the mathematical form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com