Cooking machine for tomato meat sauce pasta

A cooking machine and tomato technology, which is applied in cooking utensils, household utensils, applications, etc., can solve the problems that the taste cannot be guaranteed to be stable, and manual firing is cumbersome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

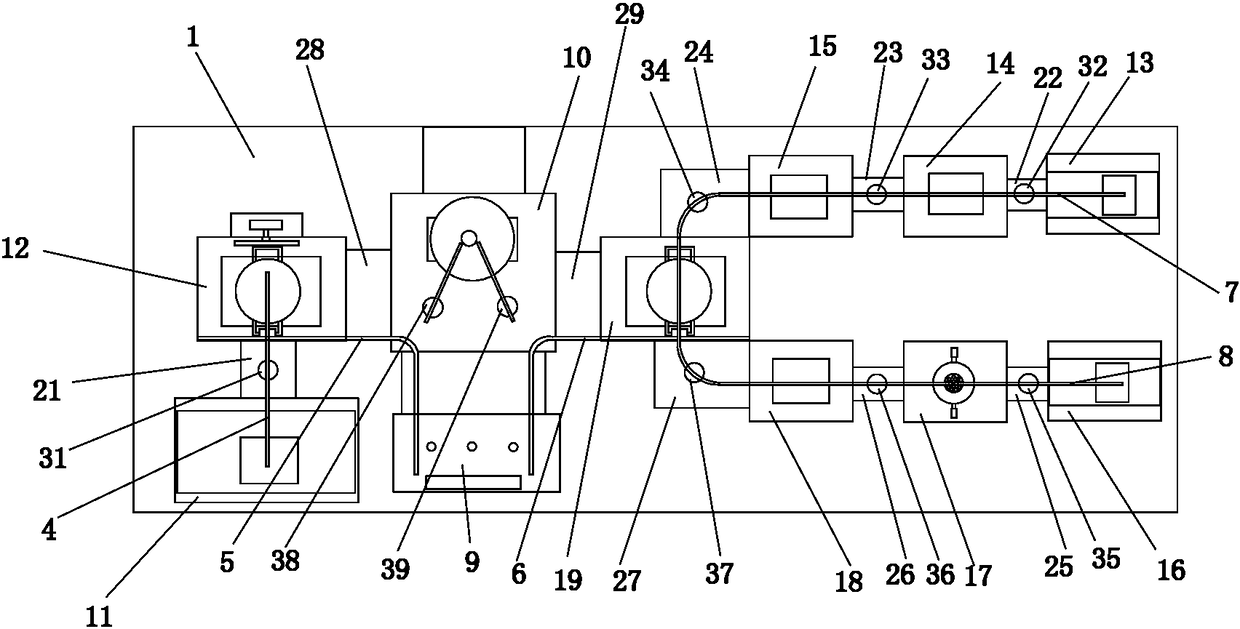

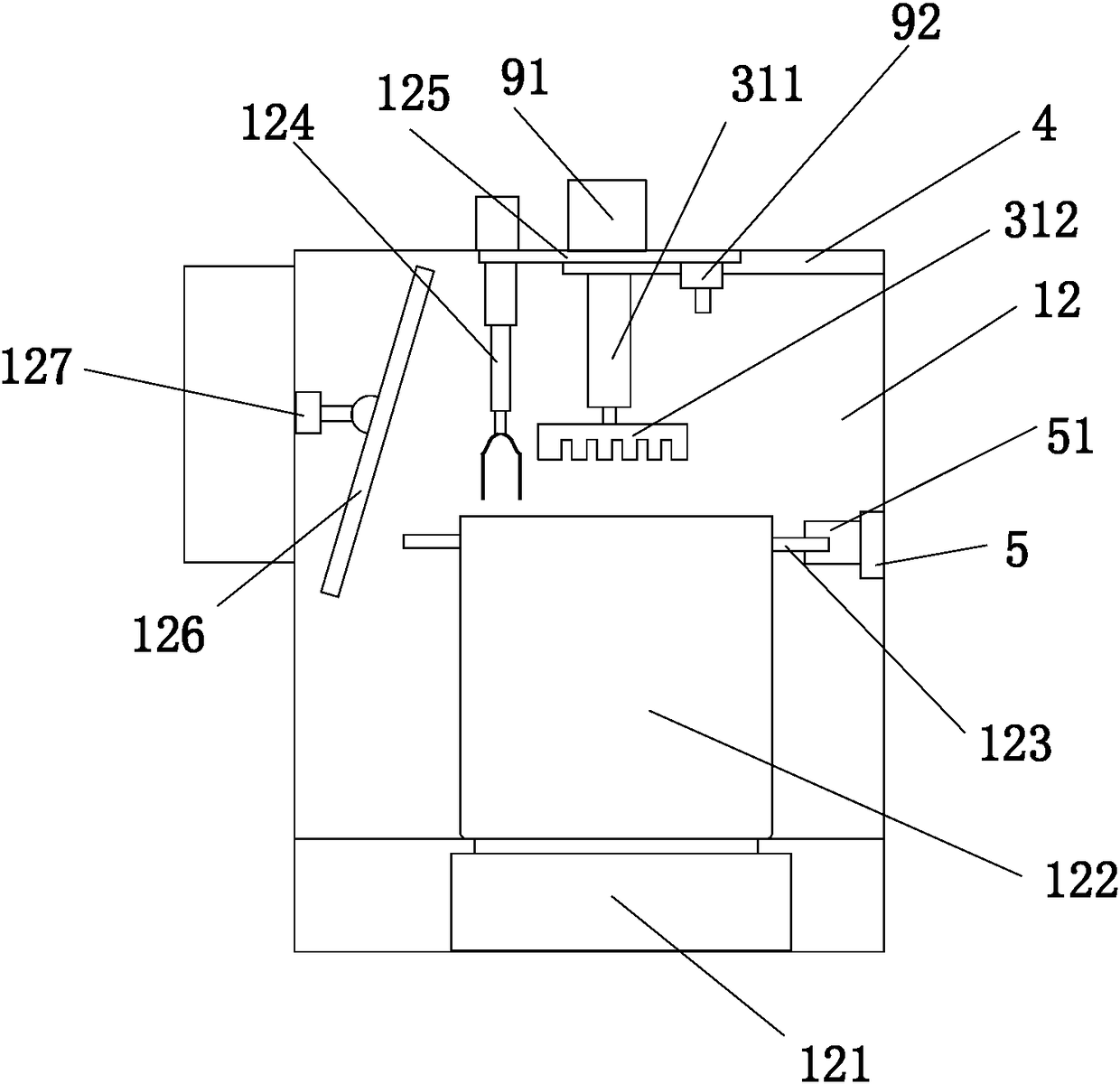

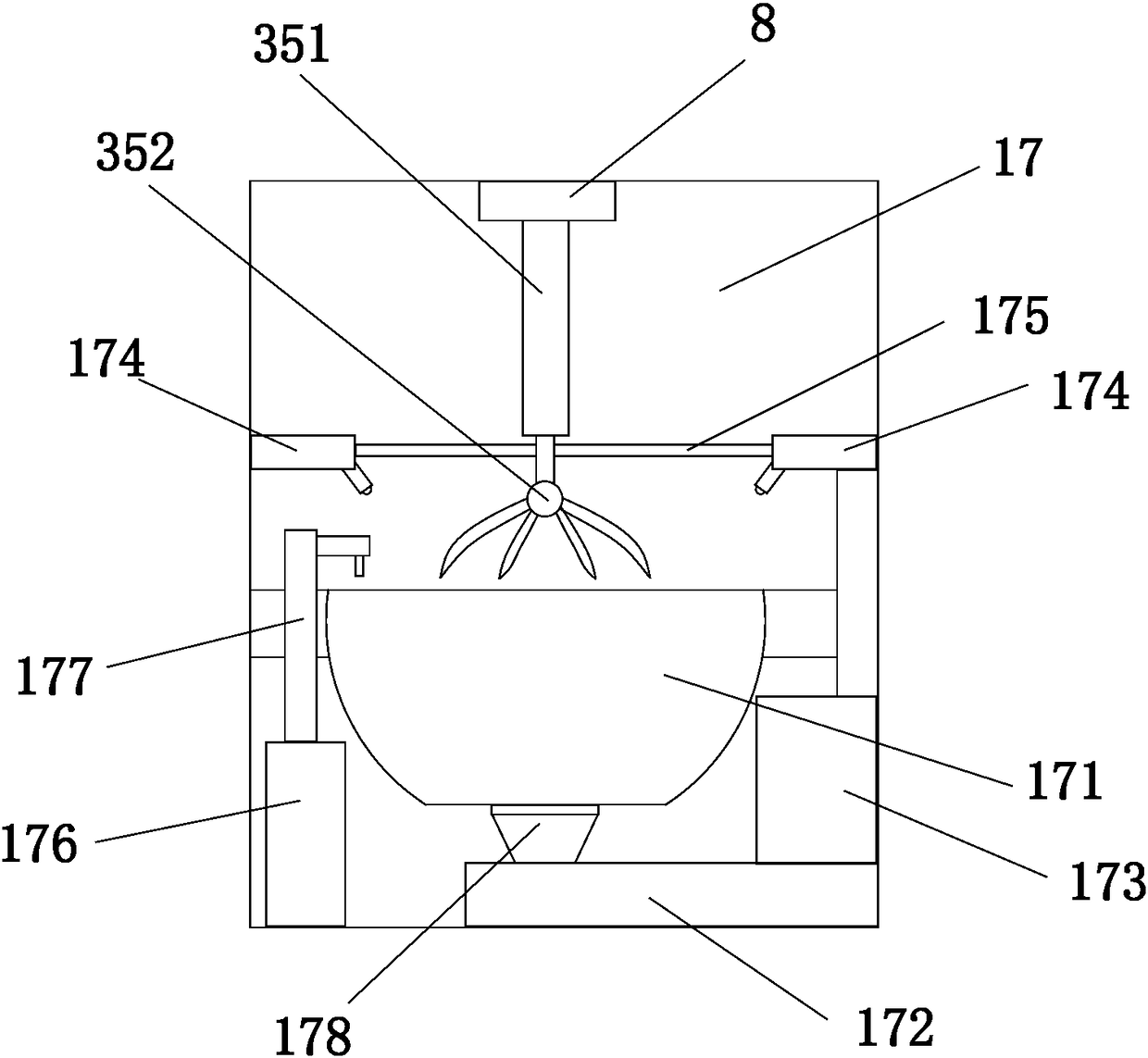

[0024] Such as Figure 1 to Figure 9 As shown, a kind of pasta cooking machine with tomato bolognese includes a main body 1, and the main body 1 is provided with a fabric box 11, a meat box 13, a side dish box 16, several seasoning boxes 91, a noodle cooking cavity 12, Vegetable washing pool 17, vegetable cutting case 18, cooking case 19, thawing chamber 14, meat cutting chamber 15, pot washing chamber 9 and blending chamber 10. The invention also includes a control computer and corresponding sensing equipment for controlling the overall operation.

[0025]A pasta channel 21 is arranged between the described fabric box 11 and the described noodle cooking cavity 12, and a movable pasta gripper 31 is arranged in the described pasta channel 21, and the described vegetable washing pool 17 and the described A vegetable channel 25 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com