Filter housing with locking cord member

A technology of ropes and components, applied in the field of filter components, can solve the problem of not providing any

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention relates to a filter assembly. figure 1 Machine 10 is illustrated having various systems and components that are suitable for use with aspects of the invention and that cooperate to accomplish tasks. Machine 10 may embody a stationary or mobile machine that performs some type of operation associated with an industry such as mining, construction, agriculture, transportation, power generation, or another industry known in the art. For example, machine 10 may be such as a backhoe ( figure 1 shown in ), bulldozer, loader, backhoe, motor grader, dump truck, or another earth-moving machine. Machine 10 may include an implement system 12 configured to move a work tool 14 , a drive system 16 for propelling machine 10 , and a power source 18 .

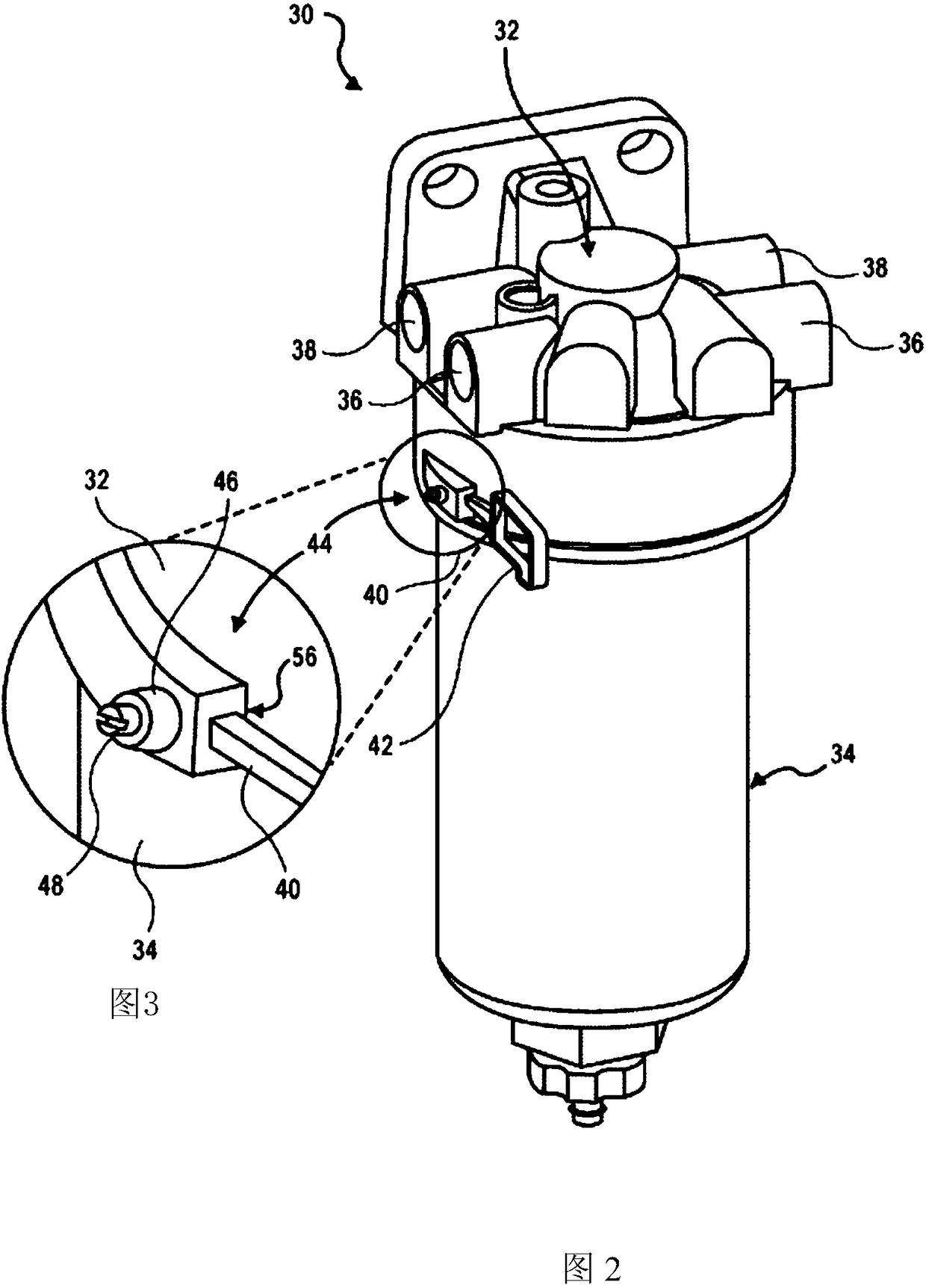

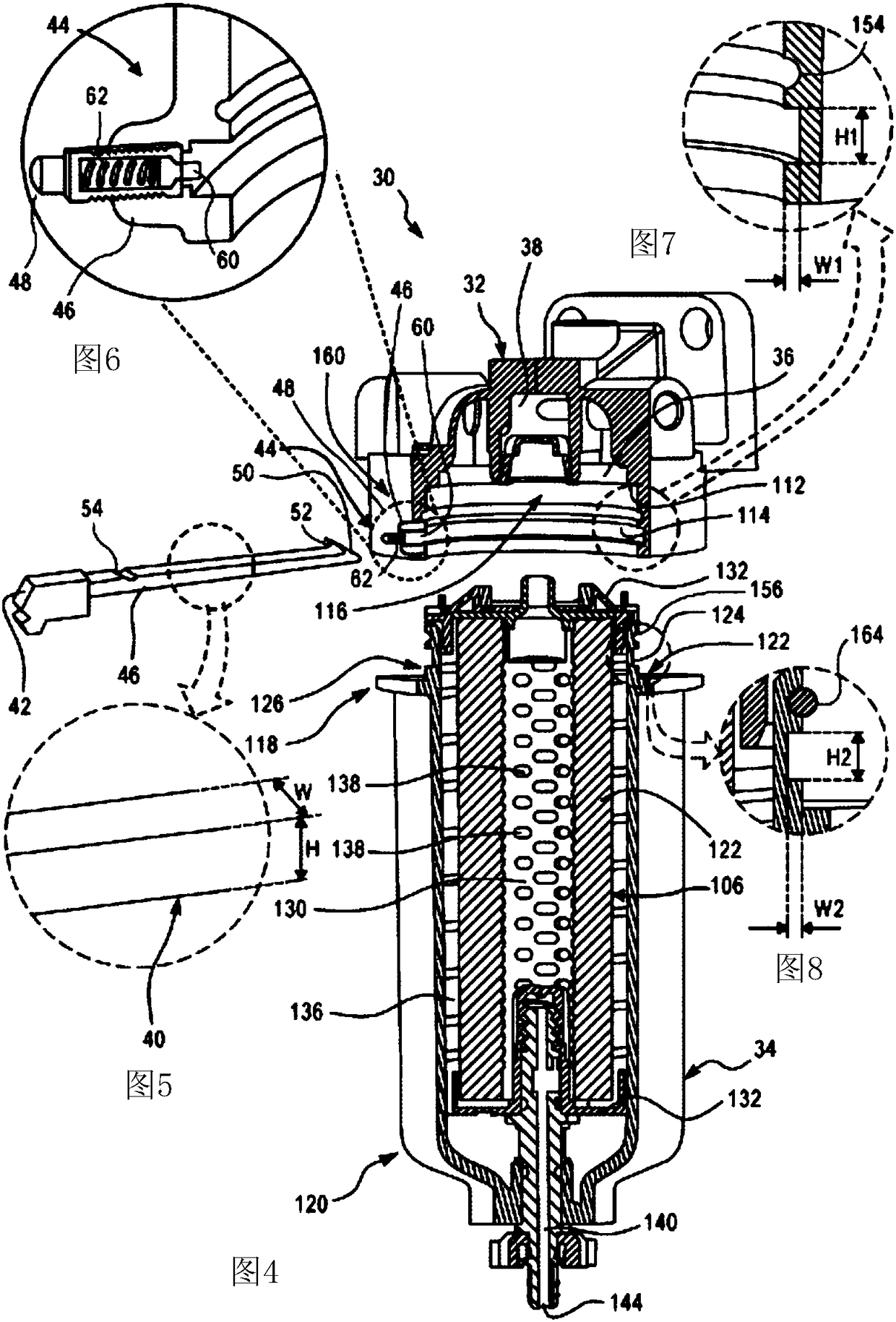

[0032] In a particular example, power source 18 includes an engine configured to combust a fuel, such as diesel, and the fuel is filtered at filter assembly 30 . As fuel passes through the filter assembly 30 , cont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap