Perpendicularity adjusting device for ultralow-position steel pipe pile adopting top-down construction method and correction method thereof

A steel pipe pile, ultra-low technology, applied in the direction of construction, infrastructure engineering, etc., to achieve the effect of saving materials, shortening the construction period, and facilitating transportation and on-site loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

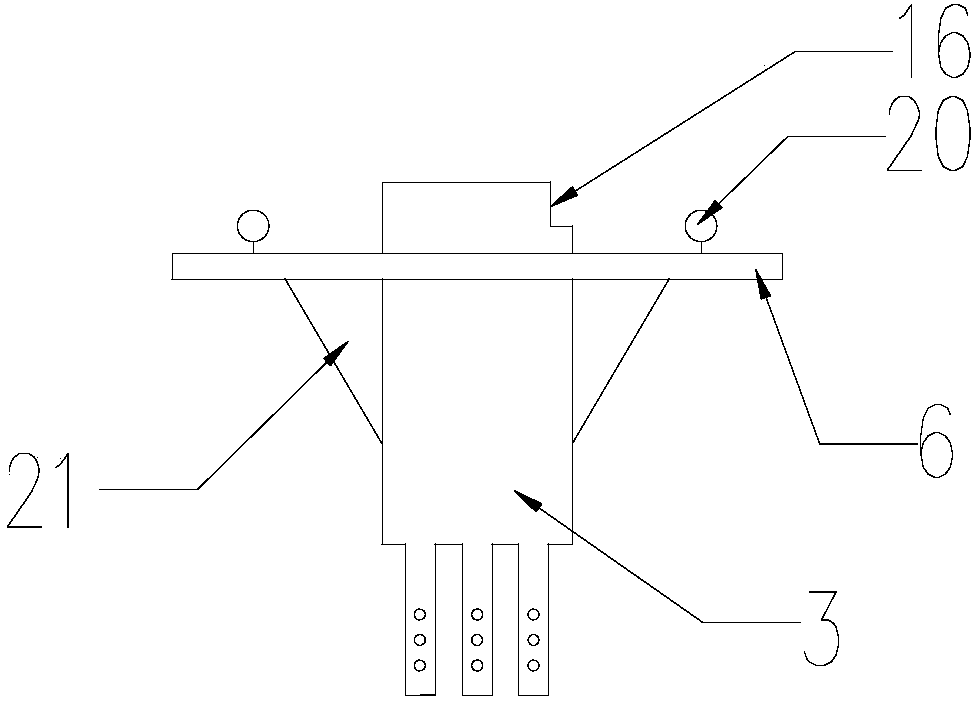

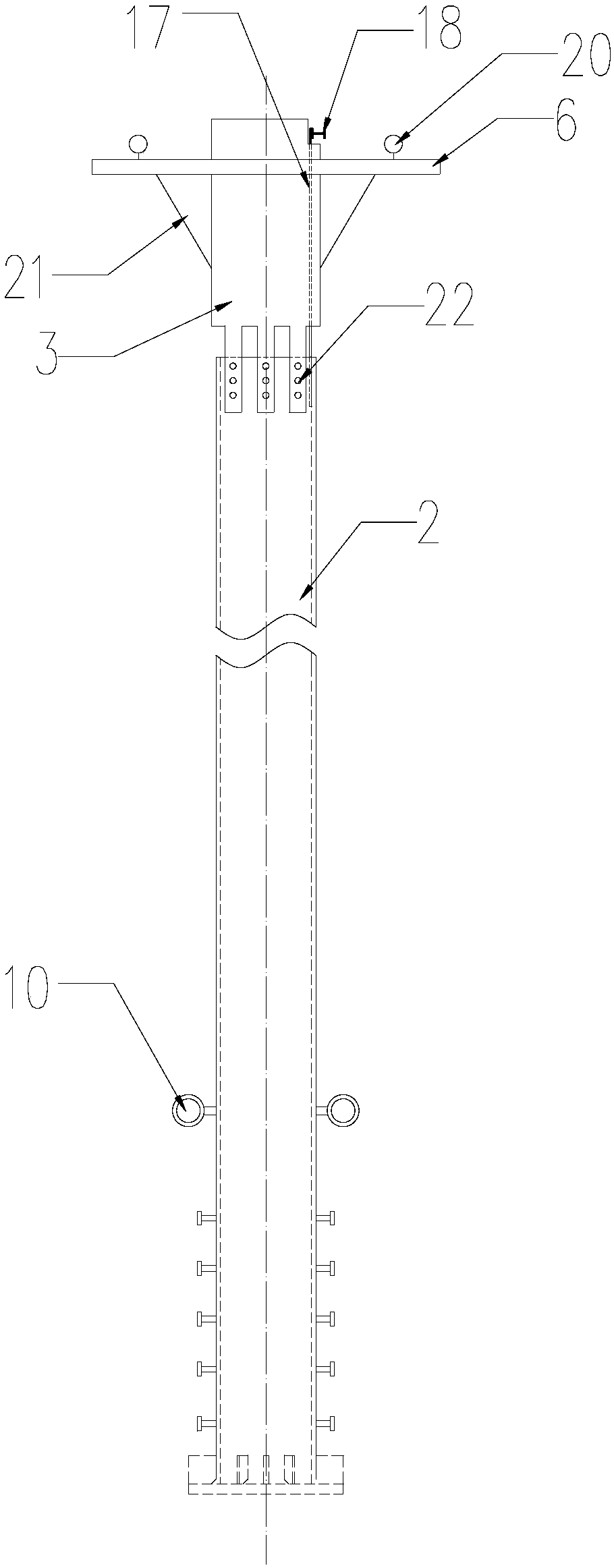

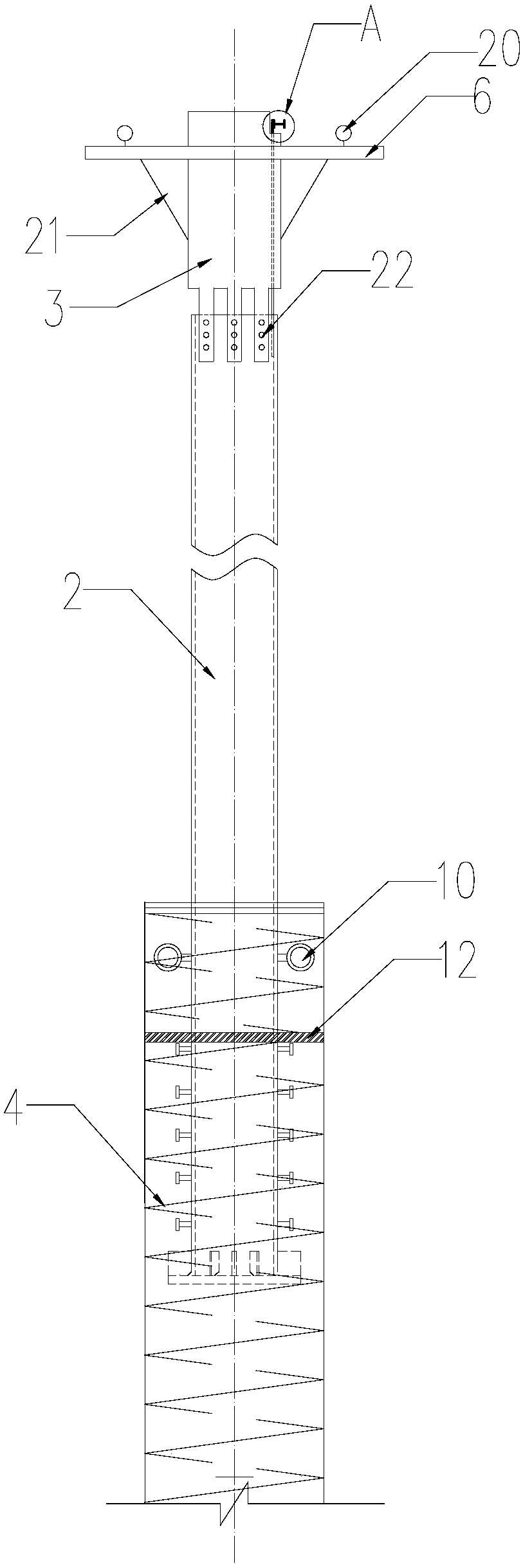

[0039] Example: refer to Figures 1 to 5 , Figure 12 , Figure 13 As shown, a vertical adjustment device for ultra-low-position steel pipe piles in the upside-down method, including the original section 2 of the steel pipe pile placed in the pile hole 1, which is set on the top of the original section 2 of the steel pipe pile and whose upper end extends out of the pile hole The long section 3 of the steel pipe column of 1 is placed in the pile hole 1 and is set on the steel cage 4 at the lower end of the original section 2 of the steel pipe pile, and the inclination measuring instrument 5 is arranged at the top of the long section 3 of the steel pipe column; The upper end of the long section 3 is provided with a support end face 6, and two symmetrically arranged through holes 61 are provided on the support end face 6, and a verticality adjustment frame 7 is provided on the side of the pile hole 1, and the support end face 6 is placed on the vertical On the adjustment frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com