Smoke exhaust type pressing fixture for laser welding plane welding

A plane welding and laser welding technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of inaccurate welding position positioning of fixtures, false welding, and fume weakening energy, etc., to ensure stability and safety, The effect of avoiding false welding or virtual welding and avoiding the phenomenon of smoke and dust explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

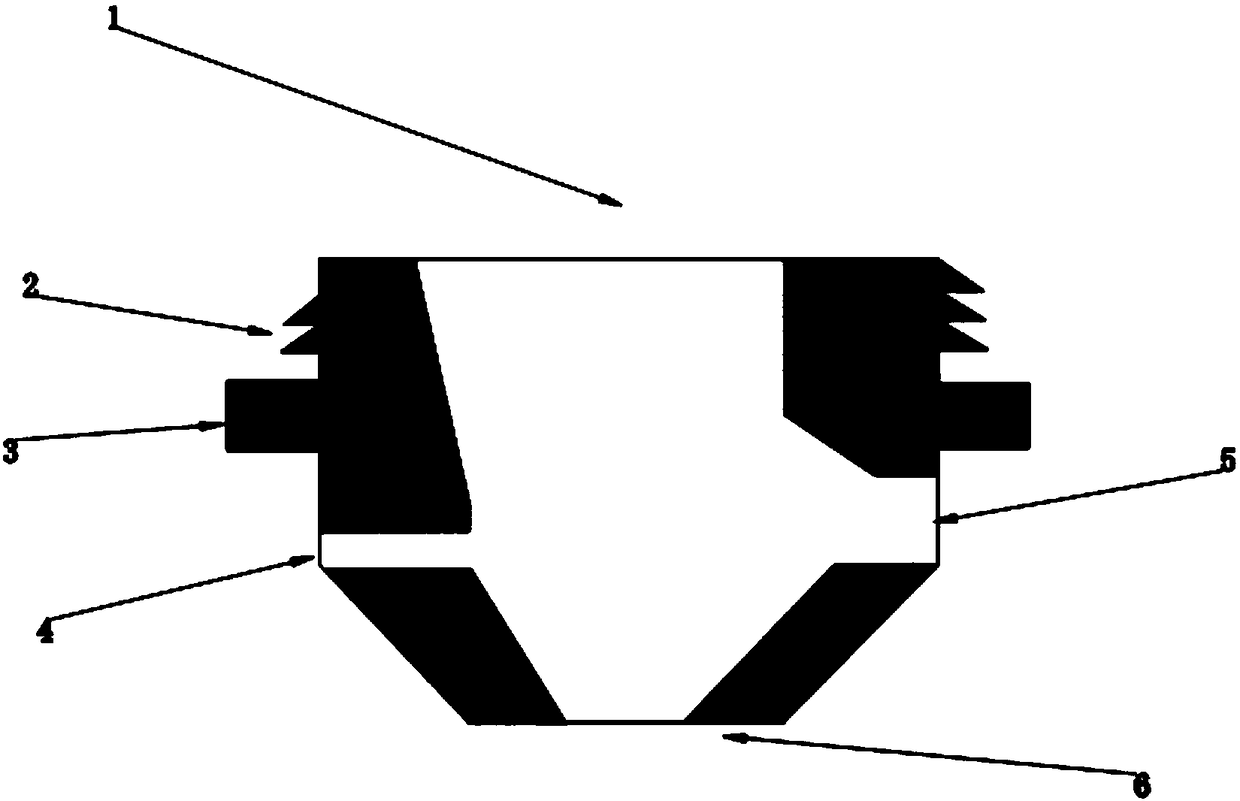

[0021] This embodiment is a smoke exhaust type compression fixture for laser welding plane welding:

[0022] Including the installation thread 2 and the installation limit stopper 3 constituting the installation assembly for installation on the equipment;

[0023] It is the same direction and intercommunicating laser inlet 1 and the contact and compression product welding port 6. The laser inlet 1 is designed with a unilateral wide opening, and the contact and compression product welding port is designed with 6 shrinkages;

[0024] The air inlet 4 and the smoke exhaust port 5 are in the same direction and communicate with each other. The smoke exhaust port 5 is designed with an inner wide mouth, and the aperture is three times the aperture of the air inlet 4;

[0025] The channel formed by the air inlet 4 and the exhaust port 5 is perpendicular to the channel formed by the laser inlet 1 and the welding port 2;

[0026] The entire laser welding plane welding smoke exhaust type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com