Split forming mixed flow turbine

A mixed-flow and split-body technology, applied in the field of turbines, can solve problems affecting turbine performance, affecting turbine operation, weakening turbine output pressure and flow, and achieving the effect of improving air supply performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

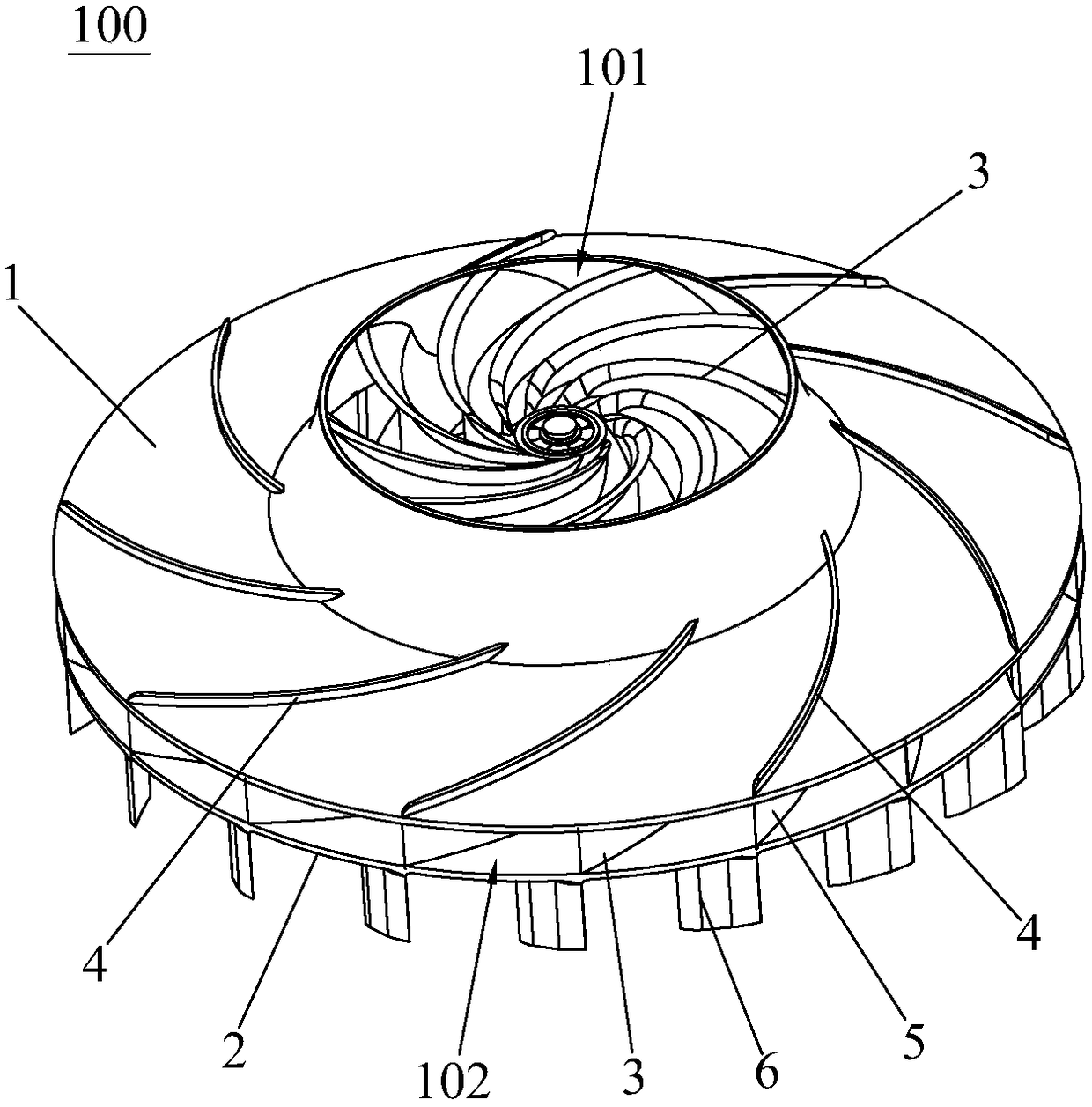

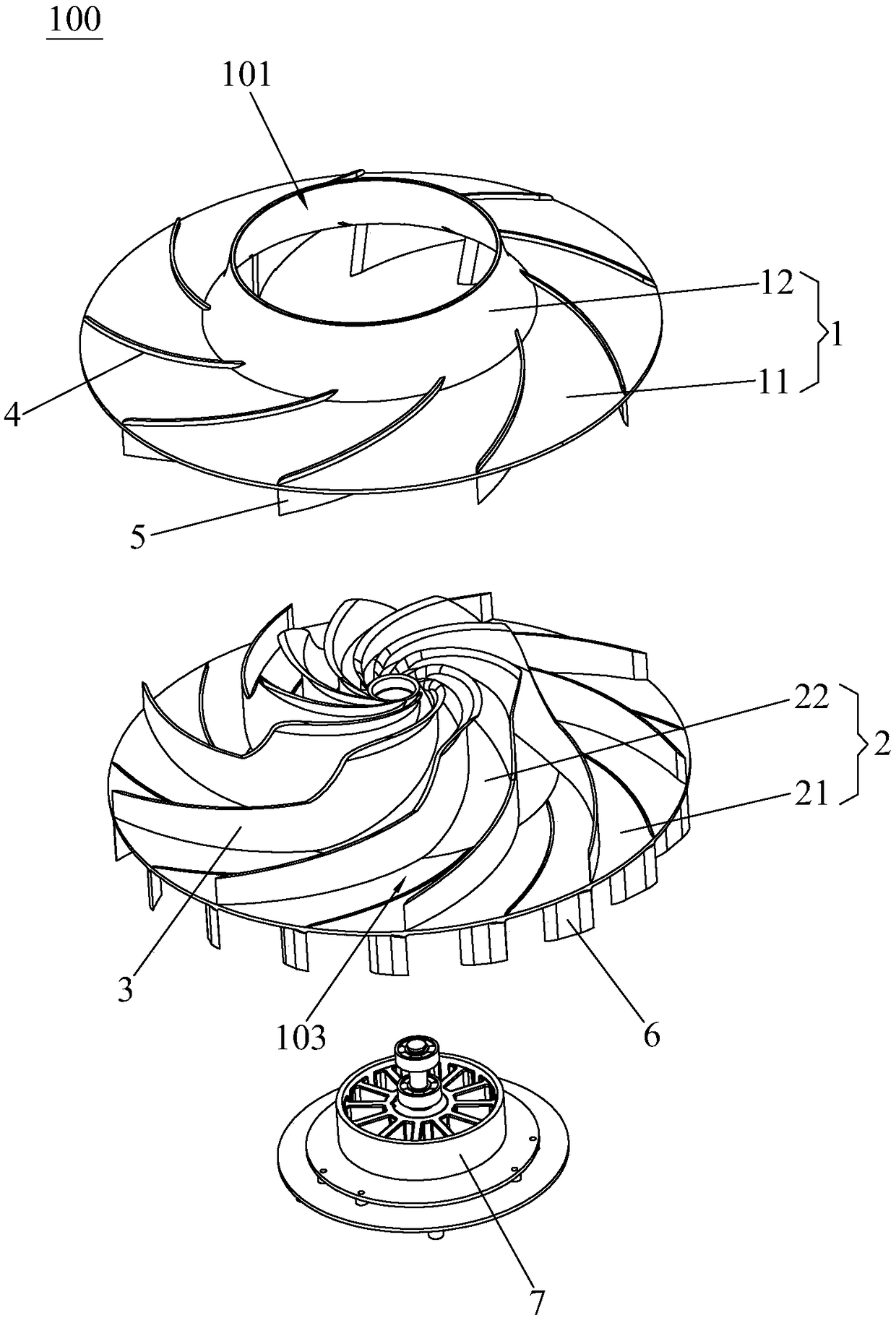

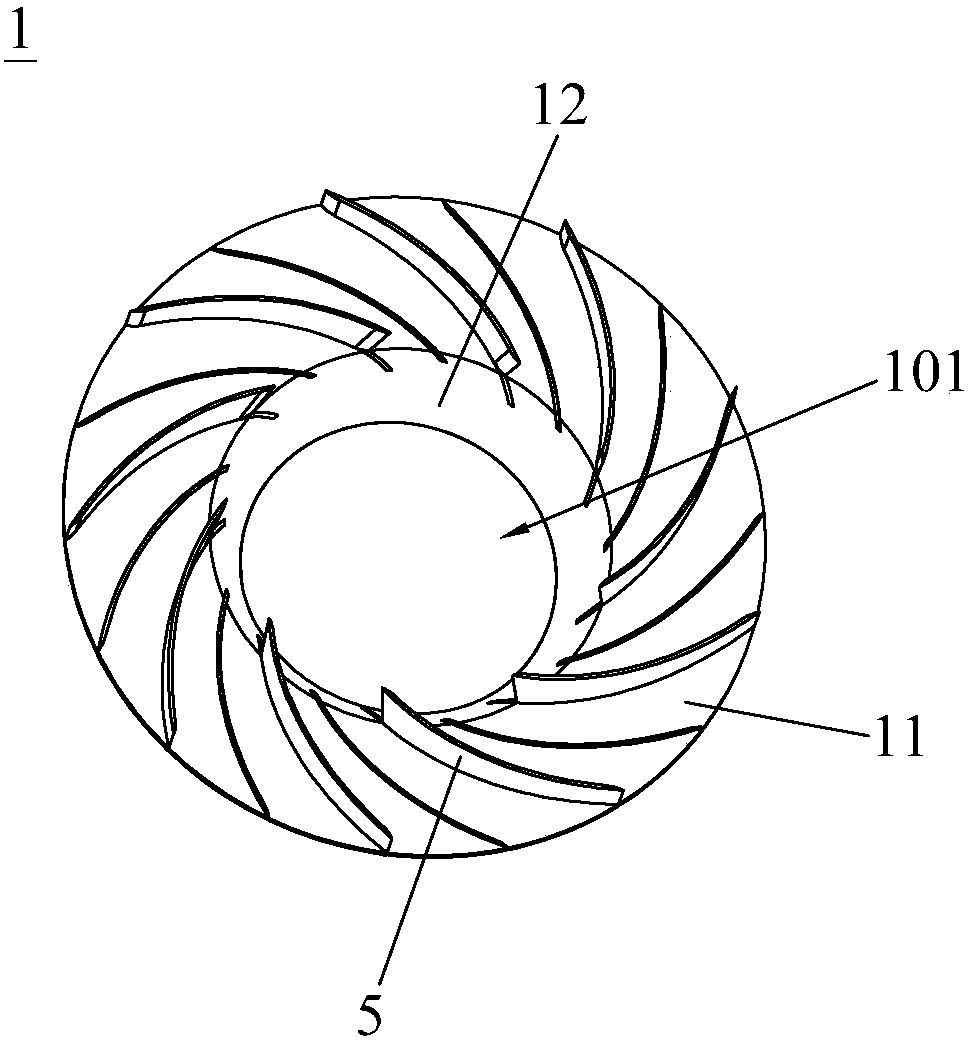

[0027] Such as Figure 1 to Figure 4 and Figure 7 As shown, the split-molded mixed-flow turbine 100 of Embodiment 1 of the present invention is installed in the outer cover 200, including the outer shroud 1 and the inner shroud 2, and the outer shroud 1 has an arc-shaped busbar. The first outer cover body 11, and the second outer cover body 12 formed by bending upwards from the inner edge of the first outer cover body 11; the inner shroud 2 has a first inner cover body 21 that is flat, and The inner edge of the first inner cover body 21 is bent upward to form a tapered second inner cover body 22 . There is a gap 201 between the outer shroud 1 and the outer shroud 200, and the inner wall of the outer shroud 1 and the outer wall of the inner sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com